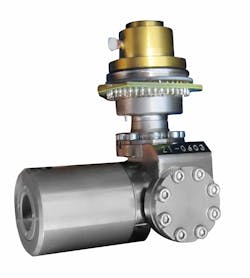

The L-HOT midwave-infrared integrated detector cooler operates at 150 K (-123°C), 60 K higher than standard mercury cadmium telluride IR detectors in the 3 to 5 μm waveband, and consumes <2 W, providing a long detection range for military applications. It has noise-equivalent temperature difference better than 20 mK and 5 μm cutoff.Sofradir

Chatenay-Malabry, Francewww.sofradir.comMore Products ----- PRESS RELEASE Sofradir boosts performance of High Operating Temperature (HOT) infrared detector Sofradir’s L-HOT MWIR demonstrator offers thermal equipment makers power efficiency with no trade-off in detection range Châtenay-Malabry (near Paris), France - Sofradir, the number one developer and manufacturer of a key class of infrared detectors for military, space and industrial applications, announces today that it will demonstrate at Eurosatory, the biennial international Land Defence and Security exhibition near Paris, a prototype High Operating Temperature L-HOT MWIR integrated detector cooler assembly (IDCA) that offers a significantly improved detection range over earlier models. The L-HOT MWIR demonstrator meets system integrators requirements to reduce SWaP (Size, Weight and Power) in military equipment. “Producing infrared detectors that are compact, lighter and save energy is driving much of our developments at Sofradir,” said David Billon-Lanfrey, VP R&D at Sofradir. “L-HOT MWIR ensures that customers get a high operating temperature IR detector with all the gains and no trade-off in image quality and NETD in order to keep the highest detection range.” NETD (Noise-Equivalent Temperature Difference), the signal over noise ratio of the IR detector is an important attribute for evaluating image quality and detection range (the ability to see smaller objects at greater distances in all weather conditions). An IR chip with high standard NETD performance is more apt at detecting slight differences in temperature between objects. This provides more detail and more accurate images, which is desirable for users looking for SWaP reductions in hand-held thermal imagers, small gimbals for small Unmanned Aerial Vehicles (UAVs) as well as long endurance systems, such as border surveillance or 24hr surveillance. Yet, with high operating temperature IR detectors and increased power efficiency comes dark current (useless information like noise) that can interfere with NETD. By using a p-on-n MCT (Mercury Cadmium Telluride) photodiode technology, Sofradir has overcome the dark current problem, while keeping the nominal five-micron cut-off wavelength. “To achieve a cut-off wavelength at five microns that enables L-HOT MWIR to offer low power consumption in a full performance IR detector with no trade-off in NETD, Sofradir switched to a p-on-n photodiode technology,“ said David Billon-Lanfrey, VP R&D at Sofradir. “With a cut-off wavelength at four microns obtained with other technologies, there are fewer input photons on the IR detector and the NETD is degraded. Our L-HOT MWIR prototype has a cut-off wavelength of five microns at 150K and that is a significant achievement.” TV format 15 micrometre pitch L-HOT MWIR integrated detector cooler assembly (IDCA) prototype operates at 150K (-123°C), 60K higher than standard MCT IR detectors (90K, -183°C) in the three to five-micron waveband and consumes less than two watts. Today, it achieves the same NETD (better than 20mK) as Sofradir’s standard full performance mid-waveband IR detectors. About Sofradir Sofradir develops and manufactures advanced infrared (IR) detectors for military, space and commercial applications. It specializes in cooled IR detectors based on a sophisticated high performance technology, Mercury Cadmium Telluride (MCT), for which it has the market lead. Its vast product portfolio of scanning and staring arrays covers the entire infrared spectrum. Sofradir also offers QWIP detectors developed in cooperation with Thales. Sofradir's headquarters are located in Châtenay-Malabry, near Paris, France. Its manufacturing facilities and those of ULIS, its subsidiary that manufactures mass volume uncooled IR detectors, are located in Veurey-Voroize, near Grenoble, France. Sofradir EC, the company’s US subsidiary, operates in Fairfield, NJ. Sofradir, ULIS and Sofradir EC employ more than 550 people. The annual turnover in 2011 was EUR 150 million (approx. USD 200 million). For more information, visit http://www.sofradir.com -----Follow us on TwitterSubscribe now to Laser Focus World magazine; it's free!

Chatenay-Malabry, Francewww.sofradir.comMore Products ----- PRESS RELEASE Sofradir boosts performance of High Operating Temperature (HOT) infrared detector Sofradir’s L-HOT MWIR demonstrator offers thermal equipment makers power efficiency with no trade-off in detection range Châtenay-Malabry (near Paris), France - Sofradir, the number one developer and manufacturer of a key class of infrared detectors for military, space and industrial applications, announces today that it will demonstrate at Eurosatory, the biennial international Land Defence and Security exhibition near Paris, a prototype High Operating Temperature L-HOT MWIR integrated detector cooler assembly (IDCA) that offers a significantly improved detection range over earlier models. The L-HOT MWIR demonstrator meets system integrators requirements to reduce SWaP (Size, Weight and Power) in military equipment. “Producing infrared detectors that are compact, lighter and save energy is driving much of our developments at Sofradir,” said David Billon-Lanfrey, VP R&D at Sofradir. “L-HOT MWIR ensures that customers get a high operating temperature IR detector with all the gains and no trade-off in image quality and NETD in order to keep the highest detection range.” NETD (Noise-Equivalent Temperature Difference), the signal over noise ratio of the IR detector is an important attribute for evaluating image quality and detection range (the ability to see smaller objects at greater distances in all weather conditions). An IR chip with high standard NETD performance is more apt at detecting slight differences in temperature between objects. This provides more detail and more accurate images, which is desirable for users looking for SWaP reductions in hand-held thermal imagers, small gimbals for small Unmanned Aerial Vehicles (UAVs) as well as long endurance systems, such as border surveillance or 24hr surveillance. Yet, with high operating temperature IR detectors and increased power efficiency comes dark current (useless information like noise) that can interfere with NETD. By using a p-on-n MCT (Mercury Cadmium Telluride) photodiode technology, Sofradir has overcome the dark current problem, while keeping the nominal five-micron cut-off wavelength. “To achieve a cut-off wavelength at five microns that enables L-HOT MWIR to offer low power consumption in a full performance IR detector with no trade-off in NETD, Sofradir switched to a p-on-n photodiode technology,“ said David Billon-Lanfrey, VP R&D at Sofradir. “With a cut-off wavelength at four microns obtained with other technologies, there are fewer input photons on the IR detector and the NETD is degraded. Our L-HOT MWIR prototype has a cut-off wavelength of five microns at 150K and that is a significant achievement.” TV format 15 micrometre pitch L-HOT MWIR integrated detector cooler assembly (IDCA) prototype operates at 150K (-123°C), 60K higher than standard MCT IR detectors (90K, -183°C) in the three to five-micron waveband and consumes less than two watts. Today, it achieves the same NETD (better than 20mK) as Sofradir’s standard full performance mid-waveband IR detectors. About Sofradir Sofradir develops and manufactures advanced infrared (IR) detectors for military, space and commercial applications. It specializes in cooled IR detectors based on a sophisticated high performance technology, Mercury Cadmium Telluride (MCT), for which it has the market lead. Its vast product portfolio of scanning and staring arrays covers the entire infrared spectrum. Sofradir also offers QWIP detectors developed in cooperation with Thales. Sofradir's headquarters are located in Châtenay-Malabry, near Paris, France. Its manufacturing facilities and those of ULIS, its subsidiary that manufactures mass volume uncooled IR detectors, are located in Veurey-Voroize, near Grenoble, France. Sofradir EC, the company’s US subsidiary, operates in Fairfield, NJ. Sofradir, ULIS and Sofradir EC employ more than 550 people. The annual turnover in 2011 was EUR 150 million (approx. USD 200 million). For more information, visit http://www.sofradir.com -----Follow us on TwitterSubscribe now to Laser Focus World magazine; it's free!

Sponsored Recommendations

Sponsored Recommendations

March 31, 2025

March 31, 2025

March 31, 2025

Voice your opinion!

Voice your opinion!