Researchers at Sun Microsystems Physical Sciences Center (San Diego, CA), Sun Laboratories (Menlo, Park, CA), and Luxtera (Carlsbad, CA) have built the lowest-energy-per-bit silicon (Si) communications transmitter (modulator plus driver circuits) to date using all complementary metal-oxide semiconductor (CMOS) processes.

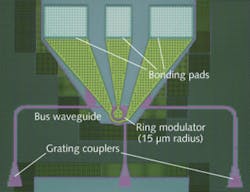

The key elements of an energy-efficient Si-based interconnect for inter- and intra-chip optical communications are a low-power modulator, a low-power driver circuit, and efficient integration of these two components. For the modulator, the researchers fabricated a ring resonator (15 µm in radius) using the Luxtera-Freescale 130 nm silicon-on-insulator (SOI) CMOS process, with grating couplers used for the optical input and output ports with surface-normal coupling. The modulator was then integrated with a separate driver circuit fabricated in its own CMOS process using flip-chip integration. The hybrid assembly was die-attached and wire-bonded to a printed circuit board and placed on a heat sink for thermal stability. Using an off-chip laser source, stable error-free transmission with a bit-error rate lower than 10-15 at a data rate of 5 Gbit/s was achieved with a power consumption of 1.95 mW, representing a record-low energy consumption of less than 400 fJ/bit. Contact Ashok Krishnamoorthy at [email protected].