Ultrathin graphene metamaterial serves applications from solar to cloaking

Researchers at Swinburne University of Technology (Hawthorn, VIC, Australia), the University of Sydney (Sydney, NSW, Australia), and Australian National University (Canberra, ACT, Australia) have collaborated to develop a solar absorbing, ultrathin graphene-based film with unique properties that has great potential for use in solar thermal energy harvesting. The work is published in Nature Photonics.

The 90 nm thick material can rapidly heat up to 160 °C under natural sunlight in an open environment, creating a pathway towards new thermophotovoltaics (the direct conversion of heat to electricity), solar seawater desalination systems, infrared light sources and heaters, modulators and interconnects for communication devices, photodetectors, color displays, and even 'invisible cloaking technology' through developing large-scale thin films enclosing the objects to be hidden.

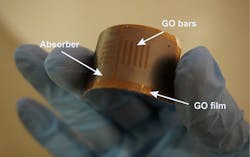

The 2.5 cm x 5 cm working prototype demonstrates the photothermal performance of the graphene-based metamaterial absorber and the researchers have also proposed a scalable manufacture strategy to fabricate the proposed graphene-based absorber at low cost.

"This is among many graphene innovations in our group," says professor Baohua Jia, research leader, Nanophotonic Solar Technology, in Swinburne's Centre for Micro-Photonics. "In this work, the reduced graphene oxide layer and grating structures were coated with a solution and fabricated by a laser nanofabrication method, respectively, which are both scalable and low cost."

"Fabrication on a flexible substrate and the robustness stemming from graphene make it suitable for industrial use," Keng-Te Lin, another author, added.

"The physical effect causing this outstanding absorption in such a thin layer is quite general and thereby opens up a lot of exciting applications," says Bjorn Sturmberg, who completed his PhD in physics at the University of Sydney in 2016 and now holds a position at the Australian National University.

"The result shows what can be achieved through collaboration between different universities, in this case with the University of Sydney and Swinburne, each bringing in their own expertise to discover new science and applications for our science," says professor Martijn de Sterke, director of the Institute of Photonics and Optical Science. "We have essentially developed a new class of optical material, the properties of which can be tuned for multiple uses."

SOURCE: Swinburne University of Technology; http://www.swinburne.edu.au/news/latest-news/2019/03/ultrathin-graphene-film-offers-new-concept-for-solar-energy.php

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.