Five-junction photovoltaic cell has 44.5% efficiency

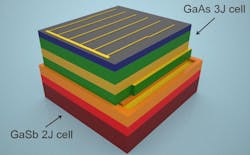

Scientists at George Washington University and the U.S. Naval Research Laboratory (both in Washington, DC), Sotera Defense Solutions (Annapolis Junction, MD), Semprius (Durham, NC), and the University of Illinois Urbana-Champaign have designed and constructed a prototype for a new solar cell that has five semiconductor junctions—three in a gallium arsenide (GaAs)-based section and two in a gallium antimonide (GaSb) section.1

The two overlapping types of photovoltaic cell each capture a different portion of the solar spectrum, allowing conversion of direct sunlight to electricity with 44.5% efficiency, giving it the potential to become the most efficient solar cell in the world. By comparison, the ubiquitous silicon solar cell converts only a quarter of the available energy into electricity.

The new device is a concentrator photovoltaic (CPV) cell that uses optics to concentrate sunlight onto a microscale solar cell at a concentration ratio of 744 suns. Because of their small size (less than one millimeter square), solar cells utilizing more-sophisticated materials can be developed cost-effectively.

"Around 99% of the power contained in direct sunlight reaching the surface of Earth falls between wavelengths of 250 nm and 2500 nm, but conventional materials for high-efficiency multijunction solar cells cannot capture this entire spectral range," says Matthew Lumb, lead author of the study and a research scientist at George Washington University. "Our new device is able to unlock the energy stored in the long-wavelength photons, which are lost in conventional solar cells, and therefore provides a pathway to realizing the ultimate multijunction solar cell."

The approach has two novel aspects. First, it uses a family of materials based on GaSb substrates, which are usually found in applications for infrared lasers and photodetectors. The novel GaSb-based solar cells are assembled into a stacked structure along with high-efficiency solar cells grown on conventional substrates that capture shorter-wavelength solar photons. In addition, the stacking procedure uses transfer-printing, which enables three-dimensional assembly of the devices with a high degree of precision.

This particular solar cell is very expensive; however, the researchers believe that it was important to show the upper limit of what is possible in terms of efficiency. Despite the current costs of the materials involved, the technique used to create the cells shows much promise. Eventually a similar product may be brought to market enabled by cost reductions arising from the use of very high solar concentration levels and technology to recycle the expensive growth substrates.

The research builds off of the advancements made by the MOSAIC Program, a $24 million research project funded by the Advanced Research Projects Agency-Energy (ARPA-E) that funds 11 separate teams across the U.S., each seeking to develop technologies and concepts to revolutionize photovoltaic performance and reduce costs. The researchers note that funding for this type of research is essential for developing viable commercial technology in the future.

REFERENCE:

1. Matthew P. Lumb et al., Advanced Energy Materials (2017); doi: 10.1002/aenm.201700345

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.