Holographic direct sound printing: Sound waves revolutionize 3D printing

A sound-based three-dimensional (3D) printing method has emerged as a groundbreaking technique in additive manufacturing, diverging from light- or heat-based printing methods by harnessing sound waves to solidify materials.1 It uses high-intensity focused ultrasound to trigger sonochemical reactions within a resin, which enables creating 3D structures without physical contact.

The core principle of direct sound printing (DSP) is its ability to focus sound waves precisely within the printing material, where it induces localized cavitation and polymerization—which selectively solidifies specific regions to form intricate structures.

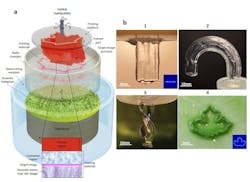

In our recent study, holographic direct sound printing (HDSP) advances DSP by introducing holographic acoustic fields that pattern ultrasound waves into complex 3D shapes to enable simultaneous printing of entire sections. Through acoustic holography, HDSP overcomes several limitations of traditional DSP to provide enhanced energy efficiency, faster printing times, and higher resolution.

HDSP’s compatibility with robotic arms also allows for greater degrees of freedom in extrusion, which expands its potential applications and versatility for complex manufacturing environments (see Fig. 1).

Potential applications for HDSP

HDSP’s unique capabilities make it suitable for a wide range of applications—from medical devices to aerospace components.

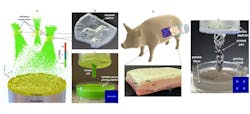

Objects at multiple planes. It enables printing objects at multiple planes, thanks to the ability of the acoustic hologram to encode cross-sectional images/information to create multiple target objects positioned at various distances from the hologram plane. This allows the simultaneous pattern formation and polymerization across different planes, based on the number of objects encoded within the hologram. HDSP also shows potential for multimaterial printing (see Fig. 2a and 2b).

Remote and challenging environment manufacturing. One of the most distinctive advantages of sound-based 3D printing, compared to conventional light- or heat-based methods, is that it can be used for remote material fabrication. This is possible because sound waves can penetrate barriers, unlike light, which is often obstructed.

HDSP’s ability to create solid structures without direct physical access to the printing area makes it well suited for manufacturing within remote or hard-to-reach environments. Figure 2c shows the printed part of our optically opaque resin. It means HDSP could enable over-the-barrier fabrication to facilitate components such as underwater for deep-sea applications.

In-body printing. In-body printing is a unique application derived from HDSP’s remote printing capabilities. This approach holds potential for noninvasive medical treatments, where precise structures can be formed in situ to facilitate targeted therapies and implants noninvasively (see Fig. 2d and 2e).

Robotic-assisted printing, printing unsupported parts. HDSP operates as a continuous solidification process due to the chain reaction of polymerization, which allows it to extend beyond a traditional 3-axis printing system. Moreover, robotic-assisted HDSP enables the creation of unsupported printed parts (see Fig. 3b) using flexible materials where the standard DSP lacks such concept. Due to the nature of the field, the over-print concept is also feasible in HDSP.

A leap forward for 3D printing

Our HDSP method represents a leap forward in 3D printing technology. By harnessing the power of ultrasound and acoustic holography, HDSP presents enhanced patterning, faster operation, and energy-efficient remote printing capabilities.

Through acoustic holography, HDSP enables multi-object and multi-material printing across multiple planes, which allows complex structures to be created remotely within challenging environments, such as in-body and underwater applications. HDSP’s integration with robotic systems also facilitates freeform, off-axis printing, which greatly expands design possibilities with more degree of freedom.

As HDSP continues to evolve with dynamic acoustic holography and 3D volumetric acoustic fields, it’s poised to revolutionize applications that demand precise, rapid, and noninvasive fabrication using sound-sensitive, advanced materials, from medical bioprinting and minimally invasive implants to resilient aerospace components and underwater structures.

REFERENCES

1. M. Habibi, S. Foroughi, V. Karamzadeh, and M. Packirisamy, Nat. Commun., 13, 1, 1800 (2022).

2. M. Derayatifar, M. Habibi, R. Bhat, and M. Packirisamy, Nat. Commun., 15, 1, 6691 (2024).

About the Author

Mahdi Derayatifar

Mahdi Derayatifar is a former PhD student in the Department of Mechanical, Industrial, and Aerospace Engineering at Concordia University (Montreal, QC, Canada).

Mohsen Habibi

Mohsen Habibi is an assistant professor in the Mechanical and Aerospace Engineering Department at the University of California, Davis (UC Davis).

Muthukumaran Packirisamy

Muthukumaran Packirisamy is a professor in the Department of Mechanical, Industrial, and Aerospace Engineering at Concordia University (Montreal, QC, Canada).