Black germanium boosts infrared photodiode responsivity

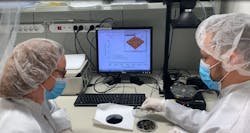

A team of Aalto University (Espoo, Finland) researchers led by Hele Savin, a professor of micro- and nanoelectronics, recently designed and built a black germanium infrared (IR) photodiode to detect IR radiation (see video).

Years ago, Savin was told it would be revolutionary to make high-sensitivity IR sensors and decided it was a challenge she wanted to take on.

“In the past, our research focused on visible and ultraviolet (UV) radiation detection—because our background is in photovoltaics and the highest sunlight intensity is found within this wavelength range,” Savin explains. “The results we’ve obtained within this wavelength range are so good that we launched a startup company called ElFys Inc. to commercialize our sensors.”

Shortly afterward, she received several requests from the semiconductor industry to also expand their research to IR radiation because it could extend the application range. And there weren’t really any good high-sensitivity solutions available—made of a material compatible with complementary metal-oxide semiconductors (CMOS)—at the time.

Germanium IR sensors

The team set out to select a CMOS-compatible material that absorbs IR, and chose germanium as their substrate material—despite the general consensus that high-performance sensors can’t be made from germanium.

Why choose germanium? It’s known to absorb IR light well, is cheap, and can be processed within the same cleanroom and on the same equipment as silicon devices.

“We’re not using a conventional p-n junction (boundary between two different semiconductor types) in our sensors to collect the signal,” Savin says. “Instead, we’re creating a signal-collecting electric field using a charged atomic-layer-deposited dielectric layer.”

Savin’s team uses special nanostructures at the surface of their sensors to eliminate reflectance losses, rather than a conventional antireflection coating. “The latter allows efficient IR photon capture, while the former enables efficient signal collection even at low light conditions,” she says.

Their sensors’ sensitivity is extremely high on a wide spectral range—from 200 nm all the way to 1800 nm. “The IR signal can be captured independent of the incoming angle, even at very low incident angles,” says Savin. “Our technology is fully CMOS compatible and uses existing processes and methods.”

Materials challenges along the way

The team faced many challenges—primarily materials-related—that had to be overcome, and it took them eight years to create functional devices.

“First, we had to find a good and stable surface passivation method, and then we needed to develop the process for nanostructuring germanium surfaces,” Savin says. “But the biggest challenge was to combine these two, for example, by developing a process for surface passivation of germanium nanostructures. After we achieved this, we knew the devices would work well and the rest was just normal process development for the other parts of our devices.”

There are still challenges ahead related to the dark current and speed of the sensors, which are “somewhat determined by the intrinsic material properties of germanium,” Savin says. But the team has ideas about ways to tackle these issues as well.

“In the beginning of our work, we were told that research into germanium sensors is a dead end,” Savin says. “But we believed in our original ideas and decided to push on. And it turned out to be a good decision because we obtained promising results on a material level.”

While the team believed their sensors would have high sensitivity compared to germanium sensors available today, “it was still a very exciting surprise to us that our sensor’s photoresponse exceeds even state-of-the-art indium gallium arsenide (InGaAs) sensors,” Savin adds.

Their germanium photodiodes outperformed all of the reference InGaAs photodiodes—both in terms of absolute quantum efficiency (EQE) at their peak wavelengths and broadness of the spectral range. Germanium photodiodes have a high photoresponse—from ultraviolet (0.2 µm) to near-infrared (NIR; 1.9 µm), with a peak responsivity as high as 1.19 A/W at 1.65 µm.

“From a scientific point of view, it’s very interesting to note that we even reached above 100 EQE when using high-energy UV photons,” says Savin. “This hadn’t been observed in germanium before because UV photons are usually absorbed within the dead layer just below the surface.”

Wide range of applications for germanium IR sensors ahead

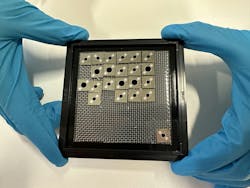

As far as potential applications for the team’s sensors, the list ranges from telecommunications to transportation to imaging to medicine. “So far, we’ve fabricated only sensor elements and detector chips,” says Savin. “We want to integrate them into final applications to see what happens. If anyone has an application where our chips could be used, please reach out because we’re more than happy to collaborate.”

What’s the next step for the team? “Scientifically, since so far we’ve made only single-pixel chips, now we want to apply our technology to imaging applications, for example, to make a matrix of the pixels. Eventually we’ll aim for infrared CMOS cameras integrated with silicon electronics,” says Savin.

Commercially, the team’s startup ElFys Inc. is already working to commercialize the technology. “Product development is already moving along, and we expect to release our first germanium IR sensors during 2025,” says CEO Mikko Juntunen.

FURTHER READING

H. Liu et al., Light Sci. Appl., 14, 9 (2025); https://doi.org/10.1038/s41377-024-01670-4.

About the Author

Sally Cole Johnson

Editor in Chief

Sally Cole Johnson, Laser Focus World’s editor in chief, is a science and technology journalist who specializes in physics and semiconductors.