Opto Diode’s Family of Ultraviolet-Enhanced Photodetectors for Medical Applications

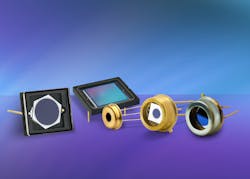

CAMARILLO, Calif. – August 15, 2022 - Opto Diode Corporation, an ITW company, provides a wide variety of ultraviolet-enhanced detectors specially designed for vital medical applications. The UVG family of photodiodes operate from 190 nm to 400 nm, and are available in two different configurations, circular and square.

The UVG100 is a large, square photodetector with an active area of 100 mm² and operates from 190 nm to 400 nm. It exhibits an excellent UV response with 100% internal quantum efficiency.

There are four circular active area photodiodes in Opto Diode’s UVG product family and they also feature superior UV response with 100% internal quantum efficiency. The UVG20C has a 20 mm² circular active area in a TO-8 package and is ideal for electron detection between 190 nm and 400 nm. The UVG5S has 5 mm² circular active area and provides detection from 225 nm to 400 nm; the UVG 20S features a circular 24 mm² active area with detection from 190 nm to 400 nm; the UVG12, with a 13 mm² circular active area and no cap (for maximum responsivity), operates from 193 nm to 400 nm.

Opto Diode’s UVG photodiode configurations are easy to integrate into new and/or existing systems. They are successfully used in laser power monitoring, photolithography, and other high-power density systems that utilize ultraviolet light.

For additional technical information and data sheet links, please go to: https://optodiode.com/photodiodes-uvg-detectors.html.

To learn more about Opto Diode’s full line of high-performance, reliable, and highly durable photodiodes, sensors, optoelectronic modules, visible and infrared LEDs, and photonics assemblies for critical applications, visit: www.optodiode.com.

Opto Diode Corporation (Camarillo, CA - www.optodiode.com), an ITW Company, delivers industry-leading sensors, photodiodes, IR detectors, photonic modules, assemblies, and LEDs.

In a recent poll, our customers cited why they chose Opto Diode over our competitors. The most important reasons were product quality and dependability, followed by flexibility and our willingness to help, even when it is the customer’s internal issue. Reliable product lifetime is also very important to our customers.

We pride ourselves in being a team player, offering real-world solutions to our customers. With long-lifetime product reliability, superior quality and fast delivery, Opto Diode delivers advanced performance sensors from the extreme ultraviolet (UV) to the mid-infrared (mid-IR). Our products provide unparalleled high-energy particle, electron, X-ray, and UV detection along with superior sensitivity to discriminate trace gases or detect heat, sparks, or flames in the mid-IR spectrum. Other products include high performance LEDs with radiometric emissions from 365 to 940 nm and IR emitters covering 1 to 10 microns.

In addition, Opto Diode can customize the entire product quality system to test, qualify, and document parts and write procedures to the customers’ own internal guidelines and specifications. This includes a paper trail, every step of the way, when needed.

Opto Diode serves a variety of industries including aerospace, automotive, biotechnology, food processing, medical, military/defense, semiconductor equipment manufacturing, and test & measurement. Our manufacturing process is in a cleanroom environment, from start to finish. Opto Diode’s domestic U.S. facility is optimized for design and manufacturing with an on-site wafer fabrication, class 1,000 to class 10,000 clean rooms, extensive assembly capabilities and packaging expertise. From prototyping to high-volume production, we manufacture wafers-to-components then package and assemble photonic modules-to-optoelectronic sub-systems. For more information, visit www.optodiode.com.