Sydor Technologies wins MM-PAD Phase II $1.15M Small Business Innovation Research (SBIR) grant from the US Department of Energy (DOE)

ROCHESTER, N.Y., [May 24, 2022] ‒ Sydor Technologies, a global leader in advanced x-ray detectors and diagnostic instrumentation for critical science missions and fundamental research, announced today that it has been awarded a Phase II Small Business Innovation Research (SBIR) grant worth $1,150,000 over 24 months by the US Department of Energy (DOE). With this additional award, Sydor Technologies will develop the next generation Mixed Mode, Pixel Array Detector (MM-PAD) for x-ray research.

The award leverages previous Phase I SBIR award results, which collaborating with the Cornell University team, produced an advanced Application Specific Integrated Circuit (ASIC) design. Proving MM-PAD pixel architecture capable of 10 kHz frame rates, the Phase I design introduced radiation hard elements meeting specifications. The new ASIC design also introduced efficiencies by allowing four-side tileable sensors and using commercial wire-bonding vendors. Reducing digital I/O per chip resulted in a compact MM-PAD2 design.

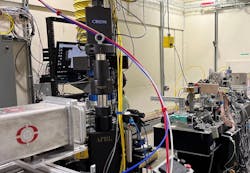

The Phase II work will develop and test a full-scale MM-PAD2 continuous imaging detector meeting the needs of synchrotron scientists. The results of this Phase II SBIR grant will provide scientists with a significant increase in frame rates and a wider dynamic range, allowing research that takes full advantage of faster and more intense x-rays now available. This in turn will provide beamline scientists and visiting users the ability to make important new measurements that help advance scientific discovery.

Proliferation of detectors with advanced performance will lead to better research data faster, resulting in exciting new discoveries. Sydor’s Technology Development Manager, Dr. Benjamin Martin, states “These developments will take the already enormous data collection capability of the MM-PAD to the next level.”