Image Processing Case Study

Let’s look at the transportation industry-based case of extensive image processing.

Two video cameras were looking at the boxes moving fast on the conveyor belt. To provide high enough image resolution the cameras were placed close to the belt but they could not cover all the belt cross-section. They were placed on the sides of the belt, and could see parts of the boxes. Customer wanted good images of the texture on the top of the boxes, so the images from the two cameras needed to be stitched.

Two cameras see the same object at different angles and distances. Before merging the images from the different cameras the images must be transformed from the coordinate systems of the cameras to one common coordinate system, and placed in one common plane in XYZ space. Our developed software performed transformation automatically, based on the known geometry of the camera positions relative to the conveyor belt.

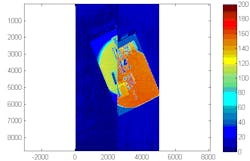

Still, after such transformation, multi-megapixel grayscale images from the left and the right cameras are shifted in common plane relative to each other:

Here grayscale images from the two cameras are shown in false color. The scale on the right demonstrates the relation between 8-bit pixel signal strength and the false color. We see that the two images also have different brightness.

Our algorithms adjust the brightness and shift the images from the left and right cameras to make merging of two images into one image possible. The resulting combined image is shown using different choice of false colors:

Right image pixels are shown using magenta, and the left image pixels are shown using green color.

Here is the zoomed version of the overlap region of the stitched image:

If the stitching would be perfect, then in the overlap region all the pixels would be gray. Our engineer saw that while there are small fringes of color on the edges of black digits and stripes, the overall stitching accuracy is good. This is not trivial, as stitching of the images obtained by different cameras, looking at nearby object from different angles, is not easy.

For comparison, here is an example of a not very successful stitching:

Avantier Inc.’s engineering team with over 30 years of experience developed software for the customer to perform all the necessary transformations automatically, without any operator intervention.