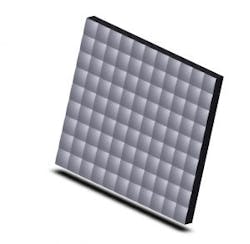

Microstructure lens arrays, also referred to as microlens arrays, are meticulously crafted arrangements of sub-lenses at the nanometer scale, assembled in a specific sequence. Each sub-lens in the array possesses its own independent optical axis. However, when viewed as a cohesive unit, these sub-lenses form a shared main optical axis. This remarkable characteristic sets microstructure lens arrays apart from conventional compound lenses, granting them an exceptional degree of parallelism. As a result, each sub-lens can transmit light sources independently and without interference.

The application of microstructure lens arrays lies within the realm of optics, particularly in the domain of microlens arrays. This innovative technology comprises a uniform pattern of countless micro lenses incorporated into the screen panel, effectively curbing the loss of light caused by internal reflections. Consequently, the screen’s brightness levels are significantly enhanced, enabling a more vibrant and captivating visual experience for the user. Distinct from this, microlens arrays represent a type of diffractive microlens and lens array featuring surface phase relief structures and discontinuous surface shapes. While there may be some overlap in their applications, microstructure lens arrays focus on tiny, lens-like structures as opposed to individual lenses, offering diverse functions in optical systems.

Application – Microstructure Lens Array

Microstructure lens arrays find their greatest utility in tailor-made applications such as beam shaping, beam homogenization, fiber coupling, and 3D imaging. Additionally, they serve indispensable roles in a multitude of fields, including medical devices, wavefront sensors, optical communication, laser optics, and metrology, among others. The versatility of microstructure lens arrays ensures their valuable presence in an array of cutting-edge technologies and industries, contributing to advancements and improvements in various optical systems.

How does a microstructure lens array achieve uniform light? What are the advantages?

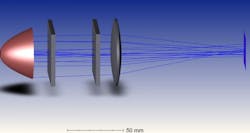

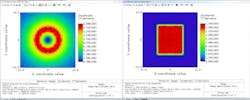

In the homogenization principle, depicted in the accompanying illustration, a laser beam passes through each individual microlens. As the light traverses these microlenses, they effectively homogenize the beam, resulting in a uniform and consistent output. This uniformity ensures a more precise and reliable optical performance, making microstructure lens arrays particularly beneficial in various applications.

How many types of microstructure lens arrays are there? What are their advantages?

Microstructure lens arrays are primarily categorized into two types: refractive microlens arrays and diffractive microlens arrays.

1. Refractive MicroLens Arrays: These function based on the refraction principle in geometric optics. As light encounters the interface of two transparent media with different refractive indices, it bends towards the region with the higher refractive index. Materials possessing higher refractive indices exhibit stronger abilities to refract incident light. Refractive microlens arrays are predominantly employed in applications involving beam shaping and beam transformation, offering tailored solutions for various optical requirements.

2. Diffractive MicroLens Arrays: Operating on the diffraction principle in physical optics, diffractive microlens arrays present a different approach. When laser light passes through each microlens, it undergoes diffraction and generates interference at a certain distance, resulting in a specific light intensity distribution. These lenses find significant utility in optical communication, medical aesthetics, and other fields, where precise light distribution patterns are crucial.

As optical technology continues to evolve, microstructure lens arrays further enhance their capabilities by combining customization and diversified beam patterns with traditional optics. The ongoing progress in laser applications augments the significance and demand for microstructure lens arrays, ensuring their steady growth in the foreseeable future. Please contact us if you’d like to schedule a free consultation or request for a quote on your next project.