Improve Your Image Quality in Telescopes with Parabolic Mirrors

Astronomical telescope is a imaging device. Its imaging quality is strongly affected by its primary component. Imaging quality is defined by the relative image intensity, which is commonly called Strehl ratio.

“The Strehl ratio is a measure of the quality of optical image formation, originally proposed by Karl Strehl, after whom the term is named.[1][2] Used variously in situations where optical resolution is compromised due to lens aberrations or due to imaging through the turbulent atmosphere, the Strehl ratio has a value between 0 and 1, with a hypothetical, perfectly unaberrated optical system having a Strehl ratio of 1.”cite :<https://en.wikipedia.org/wiki/Strehl_ratio>

A mirror with wavefront error of 1/10 wave will have 67% of relative image intensity. For this mirror, the wavefront error is twice of the surface error since the surface error is passed twice in reflection. A mirror with 1/16 wave rms wavefront error will have relative image intensity of 86%, which is generally considered reasonable good quality. The small sized waviness on the mirror also affects the image quality. This waviness is strongly associated with the manufacturing method or tool size used in manufacturing. By combining traditional method, large tool, and computer controlled method, small tool, it is the best possibility to achieve the best and affordable quality in figure (rms error) and waviness.

Another important factors in achieving sharp and bright imaging quality is the surface roughness and slope rms. These characteristics will affect how much energy is directed into imaging sensor or human eyes. To achieve an efficient imaging system with relative smaller diameter, it is necessary to specify these characteristics of the primary mirror. With the perfect combination of large and small tool polishing, this primary mirror is manufactured to achieve the best possible performance with affordability.

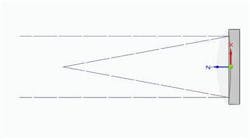

One of the primary component used in astronomical telescope is a parabolic or near parabolic shaped mirror with a f number typically larger than F4. With this f number and parabolic shape, there is a very small difference from the sphere mirror. But this small difference is key to having good image quality. Due to its small difference from sphere, this type of mirror is made with mostly traditional mirror manufacturing method combined with computer controlled figure correction method to achieve the best results.

In Parabolic mirrors the typical tolerance (wavefront) is:

1/16 wave rms or 40nm rms or better; better quality available on request

Coating: Protected aluminum; others available on request

Material: Quartz, Zerodur

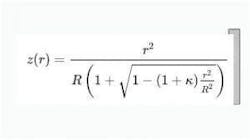

For parabolic, k=-1

Asphere Equation:

Let Shanghai Optic help you achieve the best image quality possible. For more information about custom mirrors, click here.

Learn More