Super Polished Substrates or Mirrors

For some demanding applications like DUV (deep ultraviolet) lasers, ultra-high power laser systems, and ring laser gyroscopes, high reflection and low scattering properties of the mirrors are one of the most necessary and critical points, where substrates with micro-roughness values are required to produce the mirrors containing the demanding qualities.

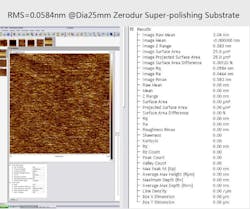

The super polishing technique is a fabrication technique often utilized to manufacture super polished mirrors substrates for optical applications. Hangzhou Shalom EO has developed an efficient and reliable super-polishing technique by modifying the classical super-polishing method, the optical substrates or mirrors produced by our technique features roughness less than 1Å on large production scales and guarantee fast delivery for our customers. Our inspection department incorporates Atom Force Roughness Measuring System and Zygo Interference Flatness Test Instrument, where we implement strict and standard quality control. Various super-polished mirror substrates of different materials including BK7, UV Fused Silica, ZERODUR, ZnSe, ZnS, Ge, Si, CaF2, MgF2, and Sapphire are available, in addition to the mirrors for Ring Gyro Lasers.

Unique classical polishing method

Although the magnetorheological(MR) fluid polishing technique( where optical surfaces are polished in a computer-controlled magnetorheological finishing slurry) seems a promising approach to achieve finishes of extremely low roughness in the fabrication of optics, its high cost and inefficient production rate make it unpractical for industrial applications. Therefore, most of the super-polished optics are made from classical polishing methods. A unique modification to the classical polishing technique is developed by Shalom EO for the production of super-polished mirrors and mirror substrates. In the processing procedure, pitch plates are configured as the mounting tool. Shalom EO is capable to realize super polished mirror and mirror substrates of <1Å roughness, 0/0 scratch/dig in the central area, and superior reflection through our state-of-the-art polishing technique. The testing results on atom force roughness measuring system shown in the top figure demonstrates that our substrates and mirrors function well in the Ring Laser Gyro Systems.