Understanding Silicon Carbide Optics

Silicon Carbide Optics

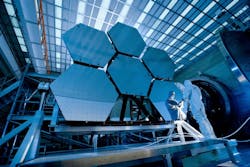

There’s a reason that silicon carbide optics are becoming more and more prevalent in the semiconductor industry as well as in aerospace, astronomy, and high energy laser applications. If you work with high temperatures or in thermally variable environments, it’s a substrate you don’t want to miss.

SiC is a non-toxic material, and it can be formed into almost any shape desired. It has low density, a low coefficient of thermal expansion and excellent thermal stability, and it also has high specific stiffness and some important resonant frequency advantages. It can transmit heat a hundred times faster than glass, and exhibits more than four times the resistance to gravity deformation. What’s not to like about silicon carbide?