Custom Optical Prism Application Examples

What is a prism?

An optical prism is a transparent optical element with flat, polished surfaces that are angled relative to each other. Prisms typically have the shape of a geometric solid with two parallel and congruent polygonal bases and rectangular or parallelogram sides.

How does a prism work?

Prisms are widely used in optical systems to manipulate and control the path of light. They are fundamental optical components, and their ability to bend, disperse, and reflect light makes them indispensable in a variety of applications.

Prisms work by exploiting the principle of refraction, which is the bending of light as it passes from one medium to another with a different refractive index. When light enters a prism at an angle, it bends, and this bending depends on the prism’s shape and material.

Prisms are used in optical instruments such as binoculars, cameras, and spectrometers, etc. Beam deviation, image inversion, and rotation are some of the effects prisms are used for. In ophthalmology, eyeglasses use prisms to correct problems like double vision. In a prism spectrometer device, a prism is used as a dispersive element that refracts light into different colors or wavelengths.

Custom Optical Prism Manufacturer – Shanghai Optics

Shanghai Optics is a custom optics design and manufacturing company, capable of tailoring the production of a wide range of prisms to meet our customers’ specific requirements. Shanghai Optics offers custom prism design, optimization, and fabrication services including customized prism coating solutions. Shanghai Optics produces many types of prisms including dove prism, penta prism, micro prism, right-angle prism, amici prism, corner cube prism, combination prism, etc.

Shanghai Optics manufactures prisms in a variety of substrates and offer custom combination prism solutions to support worldwide industrial customers and scientific researchers for best use in different applications. Below are two examples of the customized optical prisms that Shanghai Optics produced for use in scientific research applications.

Dual Amici Prism Application Example

Shanghai Optics makes custom Dual Amici Prisms for scientific research applications. The figure shows the configuration of a spectral image fusion system with Dual Amici Prism. In order to generate a high-spatial and high-spectral images, researcher designed a system with two imaging arms, i.e., multispectral imaging arm and hyperspectral imaging arm. With the use of custom dual amici prism, researchers successfully demonstrated their scientific research works through real experiments within the visible spectral range

The detailed prism design is introduced in the research article, below is a link

Dual Wedge Prism Application Example

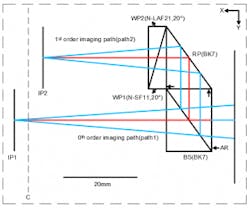

Shanghai Optics makes custom Dual Wedge for microscopy applications. The figure below shows the dual wedge prism (DWP) unit used in a 3D spectroscopic single-molecule localization microscopy (sSMLM) system. The DWP unit consists of a pair of wedge prisms, which include one with strong chromatic dispersion (WP1, N-SF11 glass, refractive index n = 1.791 at 550 nm) and another one with weak chromatic dispersion (WP2, N-LAF21 glass, refractive index n = 1.792 at 550 nm). With the use of customized dual wedge prisms, researchers successfully demonstrated a compact 3D sSMLM module with the monolithic imaging spectrometer that can readily transform a conventional optical microscope into an sSMLM.

The detailed prism design is introduced in the research article, below is a link:

https://www.degruyter.com/document/doi/10.1515/nanoph-2021-0541/html

Do not hesitate to contact Shanghai Optics today. We’d be more than happy to discuss your projects and how best they can become a success.