What Are Achromatic Waveplates?

Ever wondered how light waves can pass through a glass plate without being blocked? It’s all thanks to an achromatic waveplate! This nifty technology might sound like something out of science fiction, but it has real-world applications that make our lives easier. This blog post will explore various achromatic waveplates and explain why they are vital for modern electronic devices. We’ll also discuss some of its unique features and common applications in everyday life. Ready to learn more? Let’s get started!

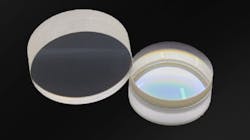

What Are Achromatic Waveplates?

Achromatic waveplates, also known as achromats, are complex pieces of technology that are often forgotten due to optics technology’s highly advanced and expansive nature. These waveplates are unique because they perform the same phase-shifting operation on light regardless of wavelength or polarization. Achromatic waveplates work in optical applications as linear polarizers, modulators, and retarders with minimal birefringence, making them much more efficient than other waveplate options.

Waveplates have been commonly used in large-scale projects such as astronomy, night vision optics, and projection systems because the modified beams of light are more precise and controlled. Without achromatic waveplates, these crucial projects would not have been successful. The ingenuity behind this underappreciated technology is truly remarkable.

Types of Achromatic Waveplates

There are various types of achromatic waveplates. Here are some of the most common:

Circular Waveplates: These are dynamic and versatile optical waveplates developed to advance to the conventional static waveplates. These waveplates are useful in several applications, ranging from laser stabilization to imaging polarimetry. While installation can prove tricky, their expansive range and ability to perform without additional external power make them an easy choice for the technologically curious. Circular waveplates offer superior achromatic performance while responding quickly to external fields.

Zero-Order Waveplates: This waveplate is made with two cylindrical or prismatic plates with no optical power. This makes zero-order waveplates highly suitable for applications involving low aberration and improved image quality. They are also advantageous in that they can be used to adjust the polarization state of light quickly, with little drift over time. They include the quarter-wave plates and half-wave plates, which are used to rotate the polarization of a laser beam by 90° and 45°, respectively.

Multiple-Order Waveplates: Multiple Order Waveplates are designed with multiple layers of crystals or film materials strategically layered together for improved performance. They can be used for multi-wavelength applications and exhibit low retardance dependency on wavelength and temperature, making them highly accurate and efficient compared to other waveplate types.

High-Temperature Waveplates: These specialized waveplates are designed for high-temperature applications and can withstand temperatures of over 100 degrees Celsius. They offer superior achromatic performance in the visible region and exhibit stable retardance values in various environmental conditions, making them an ideal choice for tough environments.

Visible/Infrared Waveplates: This type of waveplate is designed to work with both infrared (IR) and visible light, giving it greater versatility and compatibility than most other types of waveplates. It allows highly accurate beam steering with minimal birefringence while providing excellent clarity in imaging systems and laser stabilization processes.

How Do They Work?

Achromatic waveplates pass light waves through a glass plate with a specific thickness and orientation. The difference in the refractive indices of ordinary and extraordinary light causes birefringence in the material, which splits the light into two separate beams. Each beam will travel through a different optical path within the material designed and crafted to achieve phase-shifting effects between these two beams.

This feature helps maintain an even phase shift across all wavelengths of visible radiation, making it useful for various applications. In addition, a wide range of coatings can be applied to provide additional properties such as UV protection or anti-reflection. Additionally, materials such as quartz are also used in manufacturing achromatic waveplates as they provide superior performance compared to other materials due to their greater precision when cutting out specific wavelength ranges from incident white light rays.

Conclusion

Achromatic waveplates are an invaluable technology that allows us to break the barrier between light and glass. Their versatile nature makes them great for many applications, from medical imaging to laser stabilization. Additionally, their superb achromatic performance ensures accuracy in various environmental conditions.

As our understanding of optics technology increases, so does our appreciation for the achromatic waveplate. All in all, there’s no doubt that this remarkable invention will continue revolutionizing how we use light!