Latest Product in Laser Diode Arrays Makes Its Debut

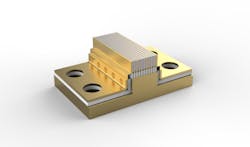

In line with the trend towards miniaturization, our company has introduced the conduction-cooled LM-808-Q2000-F-G10-P0.38-0 bar stack series. Leveraging advanced technologies such as vacuum coalescence bonding, interface material and engineering, and transient thermal management, these products achieve high integration, efficient operation, and upgraded thermal management, ensuring long-term reliability and extended lifespan.

As an essential pump source for semiconductor lasers, bar lasers face increasing demands for higher power density in the trend toward miniaturization. In response, our company has successfully developed the innovative LM-808-Q2000-F-G10-P0.38-0 model. This product precisely reduces the pitch of traditional bar products from 0.73mm to 0.38mm, significantly narrowing the width of the stack's emitting area. The number of bars in the stack can expand to 10 bars, enhancing the product's effectiveness with a peak power output exceeding 2000W, a substantial 92% increase in optical power density compared to traditional products with 0.73mm pitch.

Modular Design

The LM-808-Q2000-F-G10-P0.38-0 model combines precision and practicality, characterized by its compact, streamlined design and offering exceptional flexibility in utility. Its robust structure and high-reliability components ensure prolonged stable operation, significantly reducing downtime and maintenance costs. This is of immense value in industrial manufacturing and medical procedures.

Advanced Thermal Management Technology

For the LM-808-Q2000-F-G10-P0.38-0 model, high thermal conductivity materials, matched with the bar's CTE, are used to ensure material consistency and effective heat dissipation. Finite element methods are employed to simulate and calculate the device's temperature field, effectively controlling temperature variations through a combination of transient and steady-state thermal simulations.

Process Control

This model utilizes traditional hard solder welding technology. Process control ensures optimal heat dissipation within the set pitch, guaranteeing not only the product's functionality but also its safety and durability.

Customizable High-Power, Small Pitch, Semiconductor Laser Stacks

Our latest small-pitch, high-power semiconductor laser stacks are designed with exceptional scalability. These products can be customized according to specific client requirements, including the number of bars, output power, and central wavelength, showcasing their flexible configurability. Modular design allows adaptation to a wide range of applications, meeting diverse customer needs. This product demonstrates our relentless pursuit of innovation and customized solutions. Our company has developed higher power density bar products, offering customers an unprecedented product experience.