The first in China! 500W single-mode continuous green laser

Material vs. Laser Wavelength _

Since the birth of the first laser in 1960, after more than 60 years of development, laser, as the sharpest and most delicate knife, has been gradually applied in our lives. Combining laser with biology, medical treatment and diagnosis, and pharmaceutical science, laser therapy, laser surgery, and laser diagnosis have gradually penetrated into daily life. In the field of equipment manufacturing, high-power laser equipment is playing an increasingly important role in cutting, welding, measuring, marking and other links in high-end equipment manufacturing fields such as aviation, aerospace, automobiles, high-speed rail, and ships. In terms of fine micromachining, ultrashort pulse lasers have played an important role in the fields of photovoltaics, liquid crystal displays, semiconductors, LEDs, OLEDs, etc. substitute role. With the rapid development of semiconductor pumping technology , after years of development, near-infrared lasers with a wavelength of 1um have formed a complete industrial chain and occupy a pivotal position in industrial processing applications. In particular, the 1um near-infrared fiber laser has become the most widely used laser type because of its wide power coverage, excellent beam quality, stability and reliability.

Copper is the third most widely used metal in the world after iron and aluminum. As a modern industrial processing, copper material is one of the most widely used metal materials. The terminal demand structure of the copper industry chain covers more than 30 sub-sectors such as aerospace, high-speed trains, intelligent terminal products, electronic communications, and automobiles , and is the main indicator of high-end industrial applications. At present, the infrared fiber lasers in the 1 micron band used on a large scale have weak absorption of copper, and there are deficiencies such as large spatter and uncontrollable penetration depth in the processing of copper materials.

Figure 1 is the absorption curves of commonly used metal materials for different wavelengths of laser light. It can be seen that the absorption rate of different metals for laser light is very different at different wavelengths. Figure 2 shows the comparison curves of absorption rate at different wavelengths for metallic copper alone. At room temperature, copper absorbs less than 5% of the near-infrared wavelength (about 1 micron), so the efficiency of processing copper with infrared light is extremely low, and 95% of the laser light will be reflected and damage the laser itself ; while the absorption rate of copper for green light wavelengths ( 515nm and 532nm ) is as high as 40% . The selectivity of the material itself to the laser wavelength determines that the ideal wavelength for precision processing of high-reflection materials is a short wavelength ( ≤700nm )

Fig.1 Comparison of absorption coefficients of different metal materials

Figure 2 Comparison of the laser absorption rate of metal copper for different three wavelengths

Quoted from "New Advances in Green Laser Processing"

Compared with the short wavelength of ultraviolet laser, the current bottleneck limitation of material science cannot support the realization of stable high-power ultraviolet laser output, and ultraviolet lasers exceeding one hundred watts are extremely rare. On the contrary, through the efforts of scientists from various countries, commercial green lasers have made great progress in recent years. Trumpf of Germany and IPG of the United States have obtained ultra-high power green light output of more than 3 kW and 1 kW through disk laser technology and fiber laser technology respectively.

High-power continuous green lasers play an extremely important role in the two important problems in current industrial applications —the 3D printing of copper materials and the application of precision welding .

2. Application prospects and advantages of high-power green light

At the 14th China International Battery Technology Exhibition in 2021, Trumpf launched its 3 kW high-power continuous green disc laser. The average output power of this product is as high as 3 kilowatts, which represents the strongest power in the current green laser series, and is very suitable for welding high-reflective materials such as copper and aluminum. Especially in the lithium battery industry represented by new energy vehicle power batteries, Trumpf green laser ( 1000-3000W) can achieve up to 120 layers of copper foil welding with almost no spatter and precise and controllable penetration depth. In addition, high-power green light also has outstanding advantages in the application of 3D printing of pure copper materials. At present, there is still a blank in the country on high-power green lasers.

2.1 High anti-metal welding

Due to the superior conductivity of copper materials, copper materials are widely used in the lithium battery industry, especially in new energy vehicle power batteries. At present, the mainstream is to use high-power infrared fiber lasers for copper welding. Compared with the infrared band, the welding efficiency of copper with green light will be higher , and there is almost no spatter. Splash is fatal to battery processing, and spatter will affect the production safety, performance and life of the battery .

Figure 3. During the formation of small holes, the absorption of infrared laser light changes when copper changes from a solid state to a molten state.

Quoted from "New Advances in Green Laser Processing"

Figure 3 shows the absorption of 1064nm infrared laser by copper . It can be seen from Figure 3 that as the melting temperature increases from 0 to 1 400K , the absorption of infrared light by copper slowly increases from 5% to about 10% ; when copper reaches the melting point ( 1 400K ) , the absorptivity of copper to the infrared band laser will rise stepwise from 10% to about 17 % , and then as the temperature continues to rise, the absorptivity will increase slowly. This sudden change in absorption around the melting point can cause some of the molten material to be expelled in the form of splashes, and can also cause the pores to collapse, forcing the entire process to start over. Especially for the post-process welding of lithium batteries, the yield rate of welding has a direct impact on the cost of batteries.

Figure 4: Absorption of laser light in different wavelength bands by copper in solid and molten states

(Image credit: S. Kohl , German Institute for Photonics Technology)

Figure 4 shows the absorption curves of copper for different wavelengths (infrared, green and blue) at different temperatures. The green lines in the figure represent the absorptivity of copper to green light at 20 °C (solid state) and 1600 °C (melt state ) . At a room temperature of 20 ° C, when copper is in a solid state, the absorption rate for the green light band is about 40 % , but when the temperature rises to 1600 ° C and the copper is in a molten state, the absorption rate drops by about 5%. That is, the absorption of green light decreases slightly after the copper is melted. This feature helps to achieve a stable small hole and almost zero spatter when machining copper. This is the obvious advantage of green laser over infrared laser welding.

2.2 3D printing of pure copper material

Copper materials are widely used in high-end manufacturing due to their excellent thermal conductivity, electrical conductivity and other excellent properties. For example, in aerospace, high-speed train, automobile industry and other fields, there is a direct application demand for 3D printing technology of pure copper materials .

Figure 5 3D printing sample of pure copper material

Quoted from "New Advances in Green Laser Processing"

The laser light source for 3D printing of metal materials currently mainly uses 1um near-infrared single-mode fiber lasers. Due to the absorption coefficient of copper material, the 1um near-infrared single-mode fiber laser has the disadvantages of low absorption coefficient and great influence with temperature, resulting in low density of printed samples and poor process robustness. Green laser, as the best light source for 3D printing of highly reflective metal materials, 3D printing of pure copper materials can solve related problems well and achieve a density greater than 99.9 5 %.

Figure 6. Comparison of 3D printing light source effects of pure copper materials (cited from 3D Science Valley)

3. High-power continuous single-mode green light from Gongda Laser

Shenzhen Gongda Laser Co., Ltd. is mainly engaged in the R&D, production and sales of "advanced short-wavelength fiber lasers " and "laser precision processing solutions" . and application solutions for laser companies . At present, the main products are 5 0-500W high - power single-mode green laser and 1 00-1000W MOPA single - mode pulsed fiber laser .

Gongda Laser has been focusing on the research and development of high-power short-wavelength fiber lasers, and is the first to launch a 500W single-mode green laser: GCL-500, which can be used for high-reflective metal 3D printing and precision welding in China. GCL-500 green laser adopts the scheme of all-fiber fundamental frequency plus extra-cavity frequency doubling, and obtains a single-mode continuous green light output of up to 500W, which fills the gap of this type of product in China.

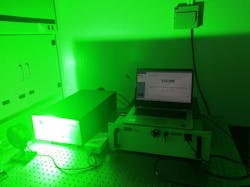

Figure 7. 500W continuous green light output power test

The main laser properties measured are as follows:

(1) Basic parameters of GCL-500

Table 1 GCL-500 basic parameters

(2) Power -fundamental frequency curve

Figure 8 500W continuous green light-frequency doubling power and efficiency curve

(3) Power stability

Figure 9 24 -hour power stability test curve

(4) Output beam quality

Figure 10 530W power output, GCL-500 beam quality M 2 test results

(5) Output spot energy distribution

Figure 11 530W power output, GCL-500 output spot test results - 2m away from the output port

4. Committed to the advanced application of short-wavelength high-power lasers

The GCL-500 CW single-mode green laser has good output power stability, excellent beam quality, and high absorption rate for high-reflection materials, especially copper, so it is expected to be applied to 3D printing of pure copper materials. By further adding a spatial modulator, pulsed green light with high-speed modulation frequency can also be obtained, which makes it also have broad application prospects in precision cutting and welding of high-reflective materials.

GCL-500 CW single-mode green laser adopts free space output, which is beneficial to ensure excellent beam quality. The laser can also provide a flexible transmission mode coupled to the optical fiber, which is more convenient to match the automatic control, and is applied to the welding process of high-reflective materials. After a long period of exploration in the laser welding process, it has been shown that a better welding effect can be obtained by using output spots (beam shaping) with different energy distributions. In addition, based on the GCL -500 single-module single-mode green laser of Gongda Laser , multi-module space or fiber beam combining can also be performed. On the one hand, green light output with flexible beam energy distribution can be obtained; on the other hand, continuous fiber green light output of thousands of watts or even tens of thousands of watts can be obtained, providing core high-quality laser welding for high-quality, high-efficiency, and high-yield Power short wavelength light source .

The continuous high-power green laser can provide an effective solution in the processing of copper materials, and is expected to shine in pure copper 3D printing and high-reflective metal precision welding.