Toughened, Low Outgassing, One Component Epoxy Features Thermal Cycling Resistance

Master Bond Supreme 17HT is a single component, no mix epoxy system for bonding and sealing applications featuring an unlimited working life at room temperature. “This thermally stable formulation has a high glass transition temperature of 410°F (210°C) and retains its bond strength at elevated temperatures,” says Rohit Ramnath, senior product engineer. “As a toughened system, it is ideal for bonding dissimilar substrates. Supreme 17HT’s unique combination of properties makes it suitable for applications involving repeated exposure to thermal cycling.” It also meets NASA low outgassing specifications per ASTM E595 testing.

Supreme 17HT possesses high bond strength properties with lap shear strength of 1,900-2,100 psi and tensile strength of 7,000-8,000 psi. This system is a reliable electrical insulator with volume resistivity of over 1015 ohm-cm at ambient temperatures and over 1012 ohm-cm at 400°F. It is serviceable from -100°F to +550°F (-73°C to 288°C). Along with its simple handling properties, Supreme 17HT offers a moderate viscosity of 100,000-150,000 cps.

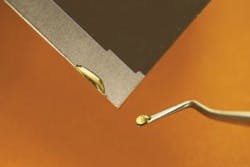

Supreme 17HT cures at elevated temperatures with cure schedule options including 300°F for 5-6 hours or 350°F for 4-5 hours. It is available in standard packaging ranging from ½ pint to 5 gallon containers as well as specialty packaging including cartridges and syringes.