Optical System Design and Challenges

At Shanghai Optics, we use the optical design tool Zemax to design, analyze, and optimize optical systems, such as lenses, objectives, cameras, and other optical devices.

In the realm of optical system design, Zemax is a vital tool used to construct virtual optical systems by defining optical specifications (surface curvatures, thickness, refractive indices, etc.).

The following are the most common use cases of Zemax during the opto-mechanical system design phase:

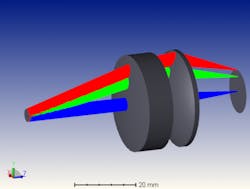

- For ray tracing, Zemax simulates the propagation of light rays through the optical system and evaluates the imaging performance of the system.

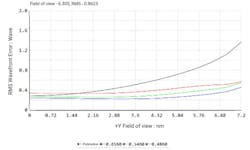

- For analysis, Zemax offers various analysis tools to calculate a variety of important parameters—ranging from the characterization of wavefront errors to the evaluation of Modulation Transfer Functions (MTF).

- For optimization, Zemax has the capability to enhance system performance. Through automated variable adjustments, encompassing lens positions and curvatures, Zemax can smoothly find the optimal configuration which meets the desired criteria and specified optimization goals. For tolerancing, Zemax performs tolerance analyses and is indispensable for the assessment of system performance repercussions stemming from manufacturing and alignment discrepancies.

In the contemporary world, optical systems have seamlessly woven themselves into the fabric of modern technology. These systems are foundational in everyday applications spanning from cameras and telescopes to medical equipment and automotive sensors. However, designing and manufacturing optical systems is a difficult task. Optical engineers find themselves immersed in a variety of formidable challenges during the design and production journey, such as correcting optical aberrations, achieving tight tolerances, and navigating complex global supply chains.

Correcting optical aberrations is one of the most difficult aspects of optical system design and manufacturing. Aberrations are imperfections in the imaging process that result in distorted or blurred images. These imperfections can be caused by a variety of factors, including lens curvature, material properties, and the refractive index. Correcting for these aberrations requires a deep understanding of optics, advanced mathematical models, and sophisticated manufacturing techniques. The following is a guide to how optical engineers navigate their way through the intricate process of correcting optical aberrations.

- To correct for optical aberrations, optical engineers use a combination of techniques such as geometrical optics and ray tracing. Geometrical optics is a more straightforward approach that models the behavior of light as it passes through an optical system. Conversely, ray tracing is a more complex approach that takes into account the refractive index of the materials used in the optical system.

- The design process for correcting optical aberrations involves several steps. First, the optical engineer must define the imaging quality requirements for the system. This involves determining the focal length, field of view, and other critical parameters. Next, the engineer must create a preliminary design using optical design software, which can calculate the expected aberrations in the system using aberration theory.

- Once the preliminary design is complete, the engineer will refine the design using a merit function (a mathematical formula that calculates the difference between the desired imaging quality and the actual imaging quality of the system). The engineer then uses this information to adjust the design parameters until the actual imaging quality meets the required specifications.

Another difficult aspect of optical system design and manufacturing process is

achieving tight tolerances. Optical systems are beholden to stringent specifications in terms of accuracy, precision, and repeatability. Achieving these tolerances requires highly specialized equipment and expertise in precision engineering, machining, and metrology.

One other aspect of the optical manufacturing process is managing the supply chains necessary for the production of optical components. These supply chains can be complex and often span multiple countries. First, raw materials such as glass, plastics, and metals must be sourced from around the world. Then, the multi-step manufacturing process begins, and this includes grinding/polishing lenses, coating surfaces with anti-reflective materials, and assembling the optical system.

In summation, the process encompassing the design and fabrication of optical systems is a journey filled with intricacy and challenge. With the many obstacles that emerge in the design and manufacturing process, a deep understanding of optics, mathematical models, and manufacturing techniques are an absolute must. In the backdrop of an expanding demand landscape for optical systems, the manufacturing industry and supply chain will evolve in tandem, evolving to meet the demands of a dynamic market.

Do not hesitate to contact Shanghai Optics today. We’d be more than happy to discuss your projects and how best they can become a success.