Optical Design for High Performance and Cost Optimization

Optical design is the process of studying application requirements and designing optical systems to meet specific needs of optical instruments. For a complex device, the entire system may include many optical components, light sources, sensors, electronics boards, display device, etc. Every component plays a unique role in the system and has its contributions to the overall performance of the optical instrument. A complex device with many optical and optoelectronic components can be easily designed to have a very high production cost if the optical system design is not optimized.

Shanghai Optics engineering team has a sophisticated system level design knowledge and a deep understanding optical characteristics of optoelectronic components, optical system design, optical manufacturing tolerances and fabrication costs. We have more than 55 years of experience in helping our customers designing and manufacturing optical components / assemblies for cost reduction and improving the system performance.

Whether you need us to develop a diffraction limited optical system, build a prototype system, or redesign an optical component / assembly product for lowering the cost and improving the performance, our engineering team is ready to take on your most demanding optical challenges.

Case 1: Avoiding a Use of High-Cost Precision Aspheric Lens

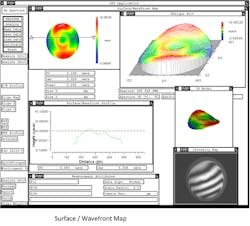

To improve optical performance, many researchers and engineers have been trying to use extreme precision aspherical lenses in optical systems without recognizing the aspherical lens cost. Understanding the complexity and cost of manufacturing and testing high precision aspheres can help us make the right decision when designing diffraction limited or high performance lens system. Shanghai Optics Inc. receives many customer inquiries about the possibility of lowering the cost of a high performance lens system which included a high precision asphere. Our engineering team will work with our customers for creating the most affordable and efficient solutions. For example, we received a customer request to lower the cost of an optical system which was specifically designed to use an extreme precision aspherical lens element for reducing the wavefront error. Shanghai Optics Inc. helped the customer re-design the high precision lens system for eliminating the use of the extreme precision aspherical lens. Based on the simulation, there was no difference in wavefront quality between the re-designed new lens system and the original lens system, but the newly designed lens system could be built with a much lower cost. The high performance lens system was successfully manufactured with our help. The figure below shows the test result of the surface figure error of a lens element which was used in the high precision lens system. The wavefront measurement error is smaller than 0.01 waves for the test setup.

Case 2: Using an Active Alignment Method

A precision lens product is expected to have a high level of performance. For achieving high MTF or resolution of a precision lens product, many customers have to specify tight tolerances for each lens element and mechanical component after performing a large number of Monte Carlo simulations for the lens MTF or spot size. Using tight tolerances can significantly increase the lens cost.

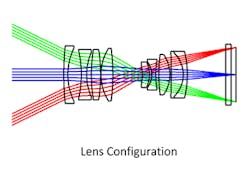

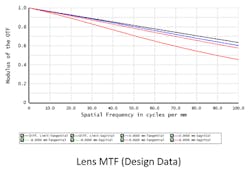

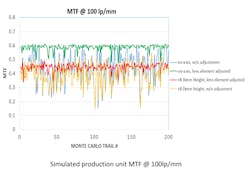

For most precision and high precision lens systems, using passive alignment techniques will not be able to meet the required high performance or the cost target. Shanghai Optics Inc.’s engineering team specializes in designing and manufacturing lens assemblies. We have requests from industrial customers who have built the lens prototype and want to maintain the high performance for the lens product. To achieve a high level of lens performance, there are some solutions such as designing a better lens, re-designing the mechanical structure for adding special features, adding centration adjustment, choosing custom spacer (spacing compensation method), using active alignment techniques, etc. We always select the method which is best suitable for customer’s situation. For example, we helped a customer to achieve the high MTF of an imaging lens product by using an active alignment method. We helped the customer redesign the lens mechanical structure for easily adjusting the position of one lens element to improve the lens MTF. Based on the 200 Monte Carlo simulations, the values of the lens on-axis MTF and off-axis (8.0mm Image Height) MTF both can be significantly increased if the active alignment method is used.

The figures below show the lens configuration, lens MTF (calculated from lens design data), and simulated optical performance (MTF@ 100lp/mm) of the lens built without using active alignment method and improved lens built with using active alignment technique.

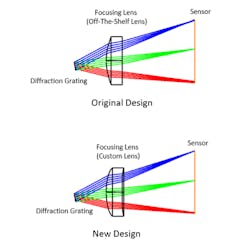

Case 3: Using a Drip-In Custom Lens

Researchers and engineers often use off-the-shelf lenses or lenses of the existing products to deliver a project faster or to reduce hours in completing a concept test or to build a prototype of a new product quicker. In some cases, a companies may use off-the-shelf lenses or lenses of the old products at the pilot testing stage of the new product or at the early production stage. As the off-the-shelf lens or the lens of the old products was not designed for this new product application, the lens cost can be high and the product performance can also be affected. Shanghai Optics Inc. receives requests from customers for redesigning the lens which could fit into the existing product design and also could improve the optical performance of the new product.

Recently we helped a customer re-design a focusing lens of a miniature spectrometer. The customer used an off-the-shelf lens for the prototype test. The objective was to reduce the lens cost and improve the spectral resolution of the spectrometer and wanted us to develop a drip-in custom focusing lens. Our engineer team worked with the customer closely when designing the new lens. The new lens is a custom aspheric lens which improve the spectral resolution and also easily molded at low cost. The Figures below show the lens performance of the original design and the new design separately.

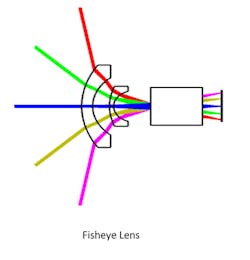

Case 4: Designing a New Lens

Shanghai Optics Inc. has more than 55 years of experience in designing and manufacturing optical components and optical assemblies for a wide variety of applications including laser 3D tracking application, 3D camera application, imaging camera application, inspection camera application, etc. The heart of any camera system or laser tracking system is the sensor. Should we use a large sensor or small sensor and how does the sensor selection affect the system performance or cost?

Many researchers or engineers select a small photodiode detector/sensor for its fast response time or select a small image sensor for its high speed image acquisition. The sensor lens usually can be small and cheap if a small sensor is used. In many cases, the sensor and sensor lens are just parts of the system. The entire system may include sensors, optical components, light sources, motorized modules, etc. For a complex system, it’s much more important to think about the system than about the individual sensor or lens component. The goal of the engineering design team usually is to develop a competitive product. We provide optical components and also consulting services to our customers for various applications. We have helped many customers make decisions on the sensor selection by providing the system level analyses of customers’ products.

For example, we helped a customer complete the optical system analysis of a new camera product for a 3D tracking application. For customer’s application, there were two types of sensors that could possibly be used and the customer was intended to use the small sensor and select an off-the-shelf camera lens. The customer contacted with us for purchasing an off-the-shelf fisheye lens.

Generally speaking, selecting a large sensor will increase the cost of the camera lens but can reduce the cost of the lighting system. We estimated the cost and provided the simulation result of the fisheye lens and LED lighting system for each sensor selection. The customer decided to use a large sensor and asked us to develop a new fisheye lens after reviewing the system performance and cost. The Figure below shows the optical design of the fisheye lens that we developed.