Enabling digital-signal processing and forward error correction

Roberto Marcoccia began his career at San Jose State University in California, where he studied electrical engineering. As a kid, he was gifted the Apple II, sparking his interest in building computers and tinkering around with electronics—the rest is history.

In 1988, Marcoccia started his first job as a software manager for Condor Systems, an intelligence-gathering company. While the applications of his work were secret, the fundamental basics of communications and digital processing remain the same. This opportunity opened up the world of radio data and provided him with a variety of experiences.

After spending his initial career in radio-frequency communications, Marcoccia joined Calient Networks as “employee number 30,” curious about the hot optical market of the late 1990s. While he didn’t work on the MEMS side of the company, he ran the systems engineering, the routing and protocol, and the hardware groups. But then, the telecommunications market bubble burst. This was a challenging, yet exciting, time for the industry, and he was deep in the thick of it. He describes this period as a “freeze,” where customers were hesitant to take on 40G long-haul communications. It was the turn of the century and customers were worried about their investments and uncertain about the future of the industry.

Marcoccia set out to establish a group that could really work well together and predict what would happen in 40G long-haul communications. In mid-2001, Marcoccia led his new group, Stratalight Communications, as the vice president of engineering. The freeze eventually thawed, with Stratalight positioned to supply a product needed by the industry. The company started off with only one room, but Marcoccia recruited a talented set of engineers he had previously worked with. Investors came on board not because of the funding, but because of the strong team Marcoccia was able to build. Those relationships from 20 years ago are so strong that one of the engineers now works with Marcoccia at EFFECT Photonics. He concludes that to have a successful company, “you must have the right team in place and the right people to make it happen.”

Stratalight gets acquired

For the next 10 years of his career, Marcoccia worked at Stratalight, but the company was acquired by Opnext in 2009. He describes the experience as “bittersweet.” During this time, there was the excitement of being acquired and a reward for all of the hard work the team had put in, but there was the bitter realization that Stratalight would not be Stratalight anymore. It was an emotional journey for Marcoccia and his team. Their biggest accomplishment occurred in 2009, when Stratalight, alongside AT&T and Cisco, demonstrated the world’s first real-time optical coherent operation.

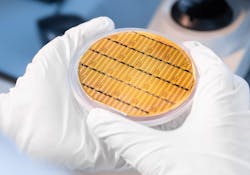

In 2010, Marcoccia moved to Juniper, where he worked for 10 years, starting as the senior director of optical systems technology and finishing as vice president of engineering for silicon photonics. Marcoccia accomplished a lot during his time at Juniper, from putting together the “How to Qualify Optics” to starting Juniper’s first 100G coherent optical transceiver to leading the effort to acquire Aurrion (2016) to commercializing silicon photonics. The acquisition of Aurrion provided Marcoccia the opportunity to work on silicon photonics for the first time. He was tasked to produce something that cost 25 cents per gigabit. Applying both silicon photonics and the heterogeneous integration Aurrion developed was the key to achieving this goal. Regardless of the type of interface, indium phosphide is required to generate light at the wavelength of choice for telecommunications in the coherent world. This was a paradigm shift for the industry!

A Dutch adventure

After his time at Juniper, Marcoccia reached out to some colleagues, and it became clear that coherent pluggable transceivers were the future—soon to be deployed not just in core networks, but also into access and data center networks. This idea sparked his interest again in coherent communications, and Marcoccia connected with James Regan, the previous CEO of EFFECT Photonics.

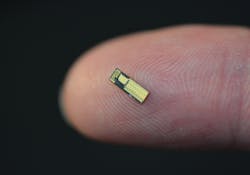

In January 2021, Marcoccia joined the Netherlands-headquartered company to develop indium phosphide-based photonic integrated -enabled transceivers. At EFFECT Photonics, Marcoccia had the opportunity to further develop indium phosphide lasers, the most critical component of the coherent interface. In April 2022, Marcoccia and his team acquired coherent DSP and FEC assets from Viasat, a team focused on optical DSP and forward error correction (FEC) technology. This acquisition was a marriage between light and digital and opened the door for EFFECT Photonics to disrupt the optical coherent communications market.

EFFECT Photonics today

With roughly 100 employees, EFFECT Photonics is an emerging company working with indium phosphide foundries and outsourced assembly and test (OSAT) manufacturing partners—Fabrinet and Jabil. In addition, EFFECT has also recently announced a collaboration with Credo on the co-development of 100G Coherent DSPs.

EFFECT Photonics is currently working on bringing coherent optical communications to different end users: data centers and access. But Marcoccia sees the future going toward coherent communications everywhere as bandwidth demands increase. He identifies two types of coherent products: one meant for performance and longer distances, and one focused on shorter distances and connecting with the data center and access. The focus on the latter will be trying to get the lowest power and cost per bit.

A great debate: Why indium phosphide?

There is often a debate within the community on how and when coherent optical interfaces will enter the data center.

Marcoccia believes indium phosphide is the best solution because it has the ability to integrate other photonics devices with the laser, which provides an advantage over other solutions. At EFFECT Photonics, the team can leverage the microelectronic ecosystems and also support the silicon photonics ecosystem from an assembly perspective because of the integration potential of their indium phosphide platform. In turn, this strategy provides a power- and cost-per-bit advantage. He notes, however, that no matter the application, light is always needed. EFFECT Photonics has the light source and is able to integrate other functions with that light on the indium phosphide platform. The company recently introduced the development of a pico tunable laser assembly (pTLA) that can also be used by the silicon-based ecosystem.A pandemic economy

Marcoccia views virtual online meetings as very productive—working for a global company headquartered in the Netherlands while living in California without the virtual component would be very difficult. But online meetings can’t replace the face-to-face interactions that are crucial to building relationships.

While Marcoccia is very efficient in the virtual setting, there is nothing like flying to see his colleagues based throughout the world. He envisions many more trips in the future as EFFECT Photonics continues to grow and open new offices worldwide.

Road ahead

Today, companies are focused on using the microelectronics ecosystem to enable integrated photonics. EFFECT Photonics takes the approach of using its indium phosphide platform and leveraging the industry’s progress with the integration of silicon photonics and electronics. Marcoccia notes that this challenge will never disappear but will continue to change forms.

Currently, EFFECT Photonics is using its indium platform to generate light and leveraging its digital processing capabilities. Generally, all applications require light creation, light detection, and data processing. In 10 years, Marcoccia envisions the company working on additional applications beyond optical communications, such as sensing and quantum key distribution. He views the applications as endless.

Marcoccia’s advice: “Put together a team that is better than you are.” He says the people he works with “are way smarter” than he is. He leads by getting out of his team’s way and letting them do their jobs. “As a leader, your job is to make sure the vision is understood and the team believes in it,” Marcoccia says.

Jose Pozo | Chief Technology Officer, Optica

Jose Pozo joined Optica in March 2022, and has spent more than 25 years working in photonics. He earned a PhD in quantum physics from the University of Bristol (U.K.), and an M.Sc. and B.Eng. in telecom engineering from UPNA, Spain / VUB (Belgium). Prior to joining the European Photonics Industry Consortium (EPIC) in 2015 as CTO, Jose was a Senior Photonics Technology Consultant with PNO Consultants, with some of the main accounts such as CERN, Thales, and TE Connectivity. He has worked at TNO, The Netherlands Organization for Applied Scientific Research, and as a postdoctoral researcher at the Eindhoven University of Technology in the Netherlands, where he contributed to the early development of EFFECT Photonics.

Ana Fowler | Market Research Analyst and Coordinator, Optica

Ana Fowler is market research analyst and coordinator at Optica (Washington, DC).