Lensed photonic-crystal fibers have long working distances

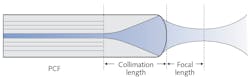

Lensed optical fibers (LOFs), which have small lenses joined to the fiber tips, are used for many purposes, including fiber-to-chip coupling, producing a collimated or focused exit beam from the fiber, and mode conversion. The lens is typically either a gradient-index (GRIN) lens or a convex tip (often made by fusing or melting); to fill the lens aperture, it is preceded by a beam-expanding region in the fiber itself, which is often a short section of coreless silica fiber (CSF). LOFs can also be fabricated from photonic-crystal fibers (PCFs), for example by heating a small length of fiber at the end to collapse air holes, naturally forming a CSF section, and melting the end to form a convex tip. However, pre-existing approaches such as the use of a discharge fusion splicer lead to inconsistent results and short collimation working distances.

Based on extensive computer modeling, researchers at Fudan University (Shanghai, China) have come up with an approach for making ultrathin lensed PCFs with long working distance, and have validated their approach using a furnace consisting of a U-shaped heated graphite element through which the fiber end is passed. For a PCF with a 125 μm diameter, the fabrication approach resulted in a fiber with an optimized collapsed length of 616 μm and a fiber-tip curvature of 170 μm; the result was a working distance of 4.84 mm, which is 4X as long as for previous methods of fabricating lensed PCFs. PCFs have large bandwidths; as a result, the experimental fiber had a large bandwidth of 770 nm (930–1770 nm, or the entire telecom wavelength range from O-band to U-band), measured by free-space-coupling two of the fiber ends and measuring the transmission loss. Reference: Y. Chen et al., early access, IEEE J. Lightwave Technol. (2021); doi:10.1109/jlt.2021.3050726.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.