Impact of DWDM on passive optical network component choices

The continued adoption of dense wavelength-division multiplexing (DWDM) technology is revolutionizing the telecommunications industry. In fact, some analysts project the DWDM system market to reach a value of $18 billion by 2032, up from $8 billion in 2022. This multiplexing technology increases the bandwidth of new or already-installed fiber networks by enabling the transmission of multiple active wavelengths of light over a single fiber.

As network engineers strive to meet the ever-growing demand for bandwidth, their choice of passive optical network (PON) components, including connectors, splitters, and muxes/demuxes, becomes critical. In this article, we explore how the increased trend toward DWDM is impacting the need for customizable components that can support higher-density deployments both indoors (central offices, data centers, or micro-edge data centers) and outdoors (outside plants).

Connectors

The adoption of DWDM technology has significantly impacted the telecommunications industry, meeting the network operator’s need for higher bandwidth but also resulting in greater traffic volumes across existing networks. This led to a critical focus on high-density deployments and more efficient use of space in rack units. As a result, equipment manufacturers have innovated upon legacy connector technology to meet these evolving needs.

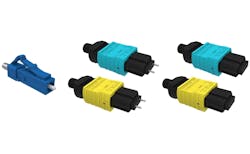

The SC or “square connector,” one of the earliest connectors to use ceramic ferrules, emerged in the 1980s as a reliable choice for fiber optics. Initially developed by Nippon Telegraph and Telephone (NTT) for gigabit ethernet networking, it became standardized in 1991 and was widely used due to its excellent performance. But as the demand for higher-density and smaller-form-factor connectors grew, the industry began to produce alternatives.

The LC connector, manufactured by Lucent Corp., introduced a smaller ferrule size and latch mechanism. This advancement enabled a significant reduction in the connector’s footprint compared to the SC, making it highly popular as a small-form-factor connector for high-density patch applications within the fiber-to-the-home (FTTH) space. But while SC and LC connectors became popular choices for network operators, the trend toward high density spurred even more innovation in recent years.

To meet the need to support more fibers in individual ferrules, the industry introduced the multiple fiber push-on/pull-off (MTP/MPO) connector. Based on the MT ferrule connector developed by NTT, the MTP/MPO connector can support up to 24 fibers in a single ferrule. Its larger size allows for increased fiber capacity, making it ideal for high-density environments like data centers. Although lab termination is required for MTP/MPO connectors, they have become extensively used at both single-mode and multi-mode wavelengths. That said, MTP/MPO connectors must be mated to an opposing male or female connector, which can lead to higher inventory costs.

Beyond the MTP/MPO are the very-small-form-factor (VSFF) connectors, including the mini duplex connector (MDC) and SN connectors. Each offers triple the fiber density of a duplex LC adapter, meaning three SN or MDC connectors can plug into the same panel space as one duplex LC. Together, these connectors help MT ferrule connector network operators do more within the limited space they have available.

As network engineers strive to accommodate growing traffic volumes facilitated by DWDM technology, the selection of connectors will play a critical role in optimizing deployment speed, cost, and performance. Having a vendor partner that can advise, test, and customize connector solutions will be critical in avoiding potentially costly mistakes.

Splitters

For outside plants, PON splitters play a crucial role in enabling the distribution of signals from a single fiber to multiple endpoints in PON architectures. With the widespread adoption of DWDM, the demand for higher-capacity splitters has significantly increased. While conventional splitters like 1:2 and 1:4 were once prevalent, advancements in splitter technology beyond fused biconical (FBT) splitters have led to the development of options that support much larger splits in relatively smaller footprints, such as 1:64 planar lightwave circuit (PLC) splitters.

Whereas a PLC splitter is a single, small device capable of large splits, FBT requires multiple splitters to be spliced together to obtain a higher split. For example, leveraging FBT technology, a 1:32 split would require 31 1:2 50/50 splitters in it along with 30 splices, which each require a protective splice sleeve. This takes up a significant amount of space, considering that a 1:32 PLC splitter is only about the same size as three FBT 1:2 splitters. When factoring in the time and labor involved in creating all these splices and fitting it all into a useable device, it becomes clear that, for higher-density needs, PLC splitters have a significant advantage.

These high-split ratio splitters have become instrumental in modern FTTH networks. As FTTH deployments continue to expand, the need for efficient use of optical infrastructure becomes paramount. High-split ratio splitters allow network engineers to serve a larger number of subscribers without the need for dedicated fibers between the head-end and end-users. This reduces deployment costs and simplifies network management.

But the use of splitters comes with its own challenges. For example, poor splitter performance (i.e., bit error rates, increased return/insertion loss) due to bad splices or dirty/damaged connectors can be difficult to pinpoint and costly to fix. There are many issues, from cross connections to macro-bends, which can negatively impact splitter performance. This makes finding a vendor who can also provide ongoing support and systems integration expertise paramount.

Customization and overall performance are also key issues when it comes to splitters. FBT splitters are customizable, enabling splits like 1:3, 1:7, and 1:11. PLC splitters are not customizable and only support standard splits like 1:2, 1:4, 1:8, and so on to 1:64. From a uniformity standpoint, FBT splitters suffer increased insertion loss variation for splits past 1:8. PLC splitters do not have this kind of restriction and maintain much more uniform losses across all of the splits. Once again, having a vendor partner with plenty of proven systems integration expertise will be critical for network engineers as they work to make the right choices for their networks.

Muxes/demuxes

Passive multiplexer/demultiplexer (mux/demux) devices are critical in DWDM networks, because they combine and separate different wavelengths of light. The increased adoption of DWDM has resulted in the need for higher channel counts and improved rack space use. Initially, passive mux/demux devices were limited in their capacity, often supporting a few wavelengths. But advancements in fiber-optic technology have led to the development of high-density mux/demux solutions.

Modern passive DWDM mux/demux modules can support a vast number of wavelengths within a single rack unit, allowing up to 96 wavelengths to coexist on a single fiber. Because fiber is expensive to run, network operators need to be more efficient with how they use their fiber. Using passive DWDM mux/demux devices, network engineers can now efficiently manage the immense volumes of traffic generated by DWDM networks while simplifying network architecture and using minimal fiber.

Customization and support are key to avoiding costly misadventures

While off-the-shelf solutions for fiber connectors, splitters, and mux/demuxes are readily available from various manufacturers, optical network engineers often encounter unique requirements that demand customized solutions beyond standard offerings. This is where the importance of a vendor partner who is not only a product supplier, but also a systems integrator comes into play.

By partnering with a vendor partner that offers both engineering expertise and the ability to deliver custom-built solutions, network operators gain a significant advantage. This type of partner should possess both in-depth knowledge of optical network technologies and the expertise to design and manufacture customized components that align precisely with the operator’s unique needs. Whether it’s developing specialized fiber connectors or DWDM modules with specific channels that standard channel plans do not accommodate, a vendor with systems integration capabilities can deliver the optimal solution and tailor it to a network operator's requirements.

Moreover, a vendor that serves as a systems integrator offers a comprehensive approach to network deployment. They can provide end-to-end support, from designing and engineering customized solutions to managing the integration and installation process. This ensures a seamless deployment experience, promotes interoperability, and minimizes headaches of trying to troubleshoot issues with multiple vendors. Having a complete solution with one point of contact is a clear benefit over attempting to seek help from many companies.

About the Author

Jerold Bahr

Solutions Engineer, Precision Optical Transceivers (Precision OT)

Jerold Bahr is a solutions engineer at Precision Optical Transceivers (Precision OT; Rochester, NY). He has more than 20 years of experience in the fiber optics industry, from hands-on development of all things passive to creating and testing custom devices in a passive optical network. With a specialization in wavelength-division multiplexing (WDM) filter integration and a vast knowledge of the hardware and connectivity used throughout, Jerold provides inside and outside plant solutions with a customized approach.