Clean fiber optics are critical for laser performance and to prevent damage

Fiber-optic technology has revolutionized long-distance data transmission—using lasers to transmit information through thin glass or plastic fibers—to ensure high-speed and dependable communications. Maintaining cleanliness within these optical systems is paramount to their performance and longevity, so it’s important to avoid contamination such as the “fiber fuse effect,” which can have disastrous consequences.

Fiber fuse effect

Light signals travel through fiber-optic cables via the principle of total internal reflection. Laser light, which carries the data, is transmitted through the fiber’s core, bouncing back and forth between the core and cladding. This mechanism allows the light to travel long distances with minimal energy loss, while the laser's power and precision are crucial for maintaining the integrity of the information being transmitted.

High-powered lasers possess immense energy and precision, which makes them indispensable tools for various industries and applications. But the remarkable power of these lasers also underscores the importance of maintaining the cleanliness of the optical components they interact with—especially fiber optics.

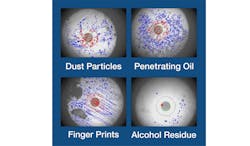

Microscopic dust, oils, or other contaminants on the fiber ends or along the cable length can severely degrade performance (see Fig. 1). Particulates and surface flaws scatter the laser light, which leads to uneven mode distribution and insertion losses. Contaminants also cause back reflections that interfere with the transmitting laser source. This causes the signal strength to drop, which reduces the range and information-carrying capacity of the link.

When a high-powered laser beam is directed toward a fiber-optic cable, the interface between the laser and the fiber end-face becomes a critical point. Any contaminants present on the fiber end-face can have detrimental consequences. This is primarily due to a phenomenon known as the fiber fuse effect.

If laser light encounters even minor impurities on the fiber end-face, it will not pass through effectively. Instead, it interacts with these contaminants and gets trapped, causing the light energy to convert into concentrated heat. This localized heat can become exceptionally intense, reaching temperatures of 1000°C.

This extreme heat serves as a focal point for the laser's energy, akin to how a magnifying glass concentrates sunlight to generate heat. The concentration of energy on these contaminants can result in multiple adverse effects, including the fusion of the contaminants onto the fiber core. As the contamination fuses with the core, it can create defects and irregularities within the fiber's structure.

In severe cases, this leads to the formation of small holes or damage within the fiber core itself. These flaws can significantly compromise the integrity of the fiber and impact its ability to transmit optical signals effectively. If not rectified promptly, the compromised fiber may exhibit increased signal loss, reduced bandwidth, and operational failure. It is so destructive that it can destroy entire miles of fiber within seconds.

This makes it critical to ensure fiber optics exposed to high-powered lasers are meticulously clean and free from contaminants. Regular maintenance and cleaning protocols can help prevent the fiber fuse effect and preserve the functionality and longevity of optical systems relying on high-powered lasers. Failure to do so can result in costly repairs, downtime, and disruptions for critical applications.

Effects on signal transmission and equipment

Contaminants on the fiber-optic cable’s end-faces can disrupt the transmission of laser light. Dust, dirt, or other particles interfere with the light's path—resulting in signal loss or reduced signal strength. Scratches or damage to the fiber end faces can also scatter laser light, which leads to distortion and interference.

Moreover, contamination can impact the transmitting components, including the laser and amplifiers along the fiber line. Optical energy can flow backward into the fiber, which affects the fiber cladding’s properties and can potentially damage the equipment. Equipment manufacturers meticulously engineer their systems to determine the appropriate power levels for the laser light source on a specific fiber link. A contaminant-free path is essential for these network systems to function properly.

Need for regular maintenance and cleaning

Fiber-optic splices and end-face connectors require regular maintenance and cleaning to maintain optimal performance and prevent damage. Microscopic but inevitable fiber contamination originates from multiple sources. Handling introduces oils and particulates. Component mating and unplugging generate wear debris between fiber end-faces. Environmental exposure leads to the accumulation of dust. Original manufacturing debris also sticks to cables and connectors. Static charge further exacerbates the attraction and adhesion of particles to fiber.

Careful handling and rigorous cleaning protocols are necessary throughout the fiber system’s lifecycle. Specially engineered cleaning tools and fluids are crucial to ensure that the fiber-optic cables remain free from dirt, dust, and other particles that can affect laser light's transmission.

Choose the right technique

Effective cleaning begins with selecting an appropriate method. While seemingly convenient, dry wiping can backfire by introducing more contamination due to static build-up. Wet-to-dry cleaning, however, helps dissolve oils and eliminate particles and also dissipates electric charges to ensure thorough cleaning.

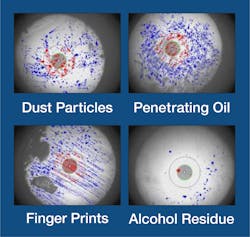

Quality fluids. The choice of cleaning materials is critical. Opt for only high-purity, optical-grade cleaning fluids to prevent residue and contamination (see Fig. 2).

Quick drying optical-grade fiber cleaning fluid helps reduce cleaning time. It also prohibits atmospheric moisture from being attracted to the fluid, which further reduces possible contamination.

Lint-free wipes. When using a wipe, lint-free varieties are essential to avoid scratching delicate fiber ends. Paper-based wipes can shed particles, which causes more harm than good. High-grade wipes will also help to reduce static charge, which may attract contamination to the fiber end-face. They are also highly absorbent to completely wipe away contamination without leaving residue or lint behind. It is also important to ensure the wipes come in sealed packages to ensure they are pure and clean prior to use.

When performing wet-to-dry cleaning using a premium-grade wipe, gently moisten a portion of the wipe with a static-dissipative cleaning solution. Be cautious not to excessively saturate the wipe, because excess cleaning fluid on the fiber can elevate the risk of re-contamination. Next, glide the end face over the wipe, moving from the dampened region to the dry section.

Fiber-optic cleaning sticks. When paired with a static-dissipating cleaning fluid, cleaning sticks represent the optimal choice for effectively cleaning end-faces with significant contamination, or to access hard-to-reach areas (see Fig. 3). The cleaning sticks must be non-linting and precisely engineered to match the end-face’s geometry to enable comprehensive cleaning without needing connector or adapter disassembly.

When using cleaning sticks, it is important to rotate the stick in one direction, usually in six rotations, and only use one stick per end-face to avoid cross-contamination.

Click-to-clean devices. Mechanical click-to-clean tools are ideal for cleaning end-face connectors with lighter contamination, or for scenarios demanding quick cleaning when time is critical. They offer exceptional convenience, rapid operation, and can effectively clean connectors of varying shapes and sizes with uneven geometries and convex configurations.

For wet-to-dry cleaning using a click-to-clean tool, moisten a wipe with cleaning fluid. Next, gently apply the tool's end to the dampened section of the wipe. Finally, insert the tool into the end-face and initiate the cleaning action by clicking. It is important to note that you should refrain from directly spraying cleaning fluid onto the end-face or the tool itself.

Don’t underestimate the importance of cleaning

The importance of clean fiber optics for laser performance and damage prevention cannot be overstated. Fiber-optic technology, with its reliance on lasers to transmit data through thin strands of glass or plastic fibers, has become a cornerstone of the modern world. But the precision and intensity of high-powered lasers also makes them particularly vulnerable to even minor contaminants that can lead to catastrophic consequences like damage to the fiber’s core structure.

To prevent contamination, consistent maintenance and cleaning are essential. Advanced cleaning tools and ultrapure fluids are vital for keeping fiber-optics free of dirt, dust, and debris that can obstruct laser light transmission. Robust cleaning protocols maintain peak performance and help avert catastrophic damage within the fragile fiber structure.

In a world growing ever more reliant on high-bandwidth, dependable communication and precise laser technologies, the importance of pristine fiber-optics cannot be overstated. Meticulous cleaning is paramount to optimize laser transmission and safeguarding these thin glass highways of light.

Rick Hoffman | Commercial Sales Manager, MicroCare

Rick Hoffman is commercial sales manager for the Sticklers Fiber Group, a division of MicroCare (New Britain, CT). He has more than 20 years’ fiber-optic network training and sales experience.