PHOTONIC-BANDGAP LASERS: Fiber laser emits from its surface

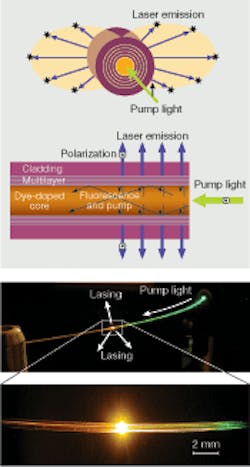

Researchers at the Massachusetts Institute of Technology (MIT; Cambridge, MA) and the University of Washington (Seattle, WA) have designed, fabricated, and characterized a photonic-bandgap (PBG) fiber laser with emission that is radially directed from its circumferential surface-unlike all other fiber lasers, which emit along the fiber axis (see figure).1 With demonstrated lasing at nine different wavelengths throughout the visible and near-IR spectrum, the surface-emitting fiber laser enables new applications in photodynamic therapy, in vivo molecular imaging, and textile fabric displays.

The surface-emitting fiber laser comprises a gain medium in the core surrounded by a PBG structure made of 58 layers of 59 nm thick amorphous arsenic selenide (As2S3) semiconductor alternating with 89-nm-thick layers of a high-glass-transition-temperature polymer, polyetherimide, with the outermost and innermost layers terminated by a 29.5-nm-thick layer of As2S3 to eliminate surface modes. By pumping the gain medium axially, the PBG structure provides the resonant cavity necessary for laser emission from the whole surface in the radial direction and at the same time is responsible for guiding the pump light.

Although a wide variety of gain media could be used within the fiber core, the researchers chose a series of organic laser dyes with different dye concentrations incorporated in a copolymer matrix. Experiments at different pump energies confirmed that the emitted radiation is indeed laser light with a pump threshold as low as 86 nJ, and not amplified spontaneous emission. The PBG fiber, which has a 70 µm core diameter, supports many cavity modes in the transverse plane. A measured Q (quality) factor of 640 is lower than expected, mostly due to limited spectral resolution of the measurement setup and losses caused by an imperfect cavity structure.

Dipole-like radiation pattern

The emission properties of the dyes used and the design of the resonant cavity produce a unique dipole-like radiation pattern for the fiber laser’s output. This radiation pattern can be modified and controlled by rotating the polarization state of the pump beam. Furthermore, tuning of the core size, dye concentration, and PBG structure allows laser light to be emitted from a spatially extended surface area along the fiber; for example, full-width-half-maximum emission along a 5 mm length is obtained for a 200 µm core fiber and 100 parts-per-million dye concentration. In addition, several dye-doped gain media can be placed in a single hollow-core fiber for selected lasing along the length of the fiber with multiple wavelength emission. Finally, shifting the bandgap by simply scaling the PBG structure and using different dyes as gain media allows lasing in the visible and near-IR wavelengths.

“Unlike commercially available photonic-crystal fibers, this fiber has a complete photonic bandgap that enables for the first time the simultaneous confinement of the transverse laser oscillations as well as the guidance of a pump beam,” says researcher Ofer Shapira. “The advantage of having a large-area, mechanically flexible laser source that can be molded to any geometry might be of great importance in several applications. In both fluorescence imaging and diffusive optical imaging, a large-area laser source that can be shaped to the geometry of the imaged object is of great importance. Other applications are flexible displays, as well as light-emitting textile clothes that can be operated both in the visible and in the near-IR (the latter with military applications in mind).”

REFERENCES

1. O. Shapira et al., Optics Express14(9) 3929 (May 1, 2006).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.