Sapphire-core glass-clad fiber has 'atomically smooth' core, low loss

Crystalline-core fibers have potential as both active and passive optical devices. Researchers from National Dong Hwa University (Hualien, Taiwan), National Taiwan Ocean University (Keelung, Taiwan), and National Chi Nan University (Nantou, Taiwan) have fabricated sapphire crystalline-core, glass-clad optical fibers that have a core surface variation of only about 1.9 Å, which they call "atomically smooth." The smoothness of the core/cladding interface results in an experimentally measured propagation loss through the fiber of on the order of 0.01–0.1 dB/cm, which is the lowest loss ever measured for conventional Ti:sapphire channel waveguides and ultrafast-laser-inscribed waveguides, according to the researchers. This low loss makes the fiber attractive for high-power devices and possibly low-threshold lasers.

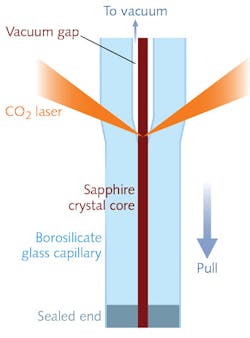

To make the fiber, a commercially available sapphire rod was heated and drawn to produce a 40-μm-diameter sapphire crystal fiber, then annealed. After placing the sapphire fiber into a borosilicate glass cladding capillary with inner and outer diameters of 50 and 320 μm, respectively, the glass capillary was laser-heated so that it collapsed and bonded to the sapphire core. To examine the core/cladding interface, the researchers viewed cross-sections of the interface with a scanning electron microscope and a field-emission high-resolution transmission electron microscope. In addition, bright-field views of the output end of the fiber were taken with an optical microscope and back-scattering spectral measurements were made of the fiber using a laser and confocal Raman spectrometer. Results showed no voids or pores at the interface or other defects, while the sapphire maintained high crystalline quality. Reference: C.-C. Lai et al., Opt. Express (2016); http://dx.doi.org/10.1364/oe.24.020089.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.