Optical Fiber Amplifiers: Multimode, multicore EDFA supports space-division-multiplexed architectures

First demonstrated at the European Conference on Optical Communications (ECOC) 2015 in Valencia, Spain, a multimode and multicore erbium-doped fiber amplifier (EDFA) has now been functionally optimized and described in detail by researchers at Nokia Bell Labs (Holmdel, NJ), Université Laval (Québec, QC, Canada), the University of Central Florida (CREOL; Orlando, FL), and Tianjin University (Tianjin, China).1 The multimode EDFA is necessary to expand the bandwidth and transmission capabilities of space-division-multiplexed (SDM) networks.

Amplifying multicore fibers

As wavelength-division-multiplexed (WDM) architectures reach their transmission limits, many networking companies are developing SDM components wherein multimode or multicore optical fibers support multiple spatial modes to increase transmission capacity for each optical fiber deployed.

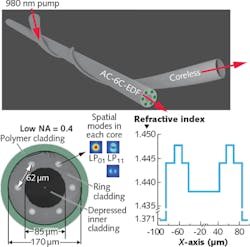

In this research, the cladding-pumped EDFA is comprised of six erbium-doped multimode cores that can each support three spatial modes, enabling amplification of 18 spatial channels simultaneously using just one pump laser diode (similar to the complexity of just one single-mode EDFA).

While typical core-pumped amplifiers usually require one laser pump diode per fiber core, cladding-pumped amplifiers can use one or a few pump lasers to amplify the signals in multiple cores. The pump is launched in the cladding modes of the fiber through a side-pumped configuration without requiring additional components such as wavelength-combining optics (see figure).

To increase pump-power conversion efficiency in the cladding-pumped scheme, the research team fabricated a special erbium-doped six-core optical fiber with an extended annular cladding region and a depressed-refractive-index inner cladding that prevents pump light from being wasted in the central region, maximizing its efficiency in the outer cladding.

For a coupled pump power of 15 W, the cladding-pumped EDFA has an output power of >20 dBm per fiber core and <7 dB noise over the entire C-band for the LP01 mode of the fiber. No pump-depletion-induced crosstalk was observed between the cores.

The researchers add that the depressed-cladding profile design can be refined and the number of cores could be increased to further enhance pump efficiency. The scalable EDFA is also amenable to different mode counts.

"In-line multicore and multimode EDFAs are critical components to the deployment of SDM links and this demonstration in a significant step in that direction," says Sophie LaRochelle of the Center for Optics, Photonics and Lasers (COPL) at Université Laval. "We believe that cladding pumping presents several advantages for these amplifiers by avoiding spatial channel demultiplexing/multiplexing at the amplifier input, as would be required for core pumping. The technique is also compatible with low-cost, high-power multimode laser diodes that, when injected in the cladding, provide a uniform pumping intensity across the area of each core."

LaRochelle adds, "With tailored doping profiles, cladding-pumping has also been proposed to reduce differential modal gain. But cladding pumping also presents challenges in terms of pump power efficiency and it is this aspect that our fiber design, with a ring cladding for the pump, addresses. It proposes a form of cladding pumping that concentrates the pump around the cores where it is needed."

The COPL, equipped with MCVD and drawing towers, is where the erbium-doped fiber was fabricated while system tests were performed at Nokia Bell Labs. LaRochelle says this project pushes the limits of current fiber fabrication techniques and has depended on a collaborative effort between multiple partners, who are now working on several improvements that will further refine the design and demonstrate higher spatial channel density.

REFERENCE

1. H. Chen et al., Nature Photon., 10, 8, 529–533 (Aug. 2016).

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.