Beam Delivery: Self-centering nanospikes deliver high-power laser light to optical fibers

Anyone who has worked in the optical-fiber industry understands that fiber-to-fiber alignment to maximize light coupling is no small task-engineers have devoted tens of thousands of hours to this challenge. But a clever new means of easily delivering laser light into a hollow-core optical fiber has been developed by researchers at the Max Planck Institute for the Science of Light (Erlangen, Germany). The technique uses the principles of optical trapping combined with a tapered, terminated optical fiber or "nanospike" to permit lensless, reflection-free, self-stabilized, and self-aligned coupling from a standard single-mode fiber to a hollow-core photonic-crystal fiber (HC-PCF) with nearly 88% coupling efficiency.1

Feeling the force

The phenomenon known as optical tweezers uses gradient forces induced by laser light in the presence of a nanoparticle to manipulate the motion of that particle. Recently, it was discovered that nanoplasmonic structures can be engineered to manipulate even nonspherical particles using relatively small laser powers in a process called self-induced back-action. Here, the magnitude of the trapping force on the object or particle is amplified by feedback from a photonic-crystal cavity or a nanoaperture in a metallic film.

A structure often used to deliver laser light into a cavity is an optical-fiber taper, whereby the fiber is heated, stretched, and sometimes etched such that light entering the taper experiences mode expansion as it travels through the tapered region. For this experiment, the researchers started with a standard 125-μm-diameter single-mode fiber (SMF), thermally tapered it to a diameter of around 400 nm, and then used hydrofluoric-acid etching to form a tip with 150 nm final diameter and less than 1 mm long.

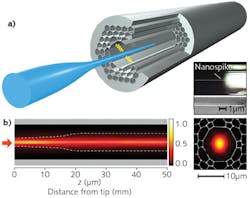

In an experiment designed to quantify the forces on the nanospike, the tip is controlled by a 50 nm step-size piezoelectric x-y-z stage and inserted into the 12.1-μm-diameter core of the HC-PCF (see figure). Light at a 1064 nm wavelength from a Nd:YAG laser is launched into the fiber tip and a 99:1 coupler monitors the input power as well as backreflections from the nanospike. The near-field profile of the resultant beam transmitted from the HC-PCF is recorded by a CCD camera and a quadrant photodiode follows the transverse motion of the nanospike as it is inserted inside the hollow core. To control ambient pressure, the nanospike and the 30-cm-long HC-PCF are contained within a vacuum chamber.

As the light travels along the nanospike (whose diameter becomes smaller than the wavelength itself), the mode-field diameter increases beyond the taper and starts to extend into the hollow core of the HC-PCF. As the tip is inserted deeper into the core, the researchers calculate the forces on the fiber because of the optomechanical interaction between the nanospike and the hollow core. It turns out that these centering forces are much stronger than a standard Gaussian beam with waist matched to the hollow core, indicating that the hollow-core structure induces a stronger back-action restoring force than typical optical tweezers, enabling self-centering and mode-matching to take place for the tip (with nearly zero Fresnel reflections).

Launch efficiency and applications

For an input power of 450 mW, a launch efficiency of 87.8% (0.57 dB insertion loss) was observed after taking into account the transmission loss of the taper (0.31 dB) and the HC-PCF (0.13 dB/m). The self-centering aspect of the adiabatic taper is encouraging for researchers needing to launch light into optical fibers without requiring optomechanical systems.

"We offer a completely new solution for coupling light into hollow-core fibers, with the unique features of self-stabilization and self-alignment," says Shangran Xie, postdoctoral fellow at the Max Planck Institute for the Science of Light. "These features are more pronounced when the laser power is higher; therefore, this technique may find potential applications in high-power laser cutting and welding. In the future, we would like to apply this technique on other hollow-core fiber systems, including gas-filled or liquid-filled HC-PCF, so that it can be extended to applications such as UV light generation and biological cell trapping."

REFERENCE

1. S. Xie et al., Optica, 3, 3, 277–282 (Mar. 2016).

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.