RALPH DELMDAHL and KRISTIAN BUCHWALD

While fiber Bragg grating (FBG) technology has been available for decades, commercial use of these devices, especially in sensing applications, has been relatively limited for two reasons. The first is that, historically, interrogation systems for use with FBGs were quite expensive. However, prices on these have dropped substantially over the past two to three years. The second limitation has been the production methods for FBGs themselves.

Specifically, sensing FBGs are still often fabricated in research labs in small quantities. The result is long lead times and high unit costs. This situation makes their use particularly problematic for sensor manufacturers since the development of a new product may require dozens of design iterations, each with slight variations in FBG properties. And, after that, it is difficult to obtain production quantities of FBGs having consistent performance characteristics.

This situation is now being addressed with a new, automated system from Northlab Photonics (Nacka, Sweden) that enables essentially pushbutton FBG production. The benefits of this system are twofold. First, it substantially reduces the unit cost for FBG production, and second, it delivers FBGs with excellent unit-to-unit consistency and quality, which greatly simplifies the task of the system integrator. This article reviews the construction, operation, and use of this system.

FBG background

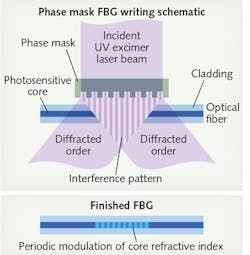

A FBG is formed by producing a periodic modulation in the refractive index of the core of an optical fiber along the direction of propagation. The periodic pattern creates a Bragg grating that acts as a filter, which because of interference reflects some of the incident optical field. Acting in a manner analogous to a high-reflection thin-film coating, the magnitude, center wavelength, and spectral bandwidth of the FBG reflectance can be precisely controlled by varying grating parameters. Specifically, these include the grating period, depth of refractive-index modulation, and FBG length.

The most obvious use for FBGs is as integrated mirrors or spectrally selective filters. They have been widely deployed for these tasks in telecommunications applications, where they can be fused directly onto the end of another fiber, eliminating the need for individual bulk components. For this same reason, they are also used extensively in fiber laser systems as resonator end mirrors.

Any change in grating period or effective refractive index, which can be introduced by either ambient temperature changes or mechanical strain, will shift the center wavelength of the FBG reflectance band. This leads to their utility as temperature and pressure (or mechanical movement) sensors.

In this role, FBGs offer several advantages over other sensor types. In particular, they are insensitive to magnetic and electromagnetic fields, and can operate without difficulty in high temperature and high pressure environments. They are largely immune to corrosive chemicals, and even nuclear radiation. In addition, they do not require electrical power and can be easily physically embedded within other structures without significantly compromising the mechanical characteristics of the material. This makes them ideal for use in a variety of extreme settings, such as nuclear plants, downhole in the oil and gas industry, and in proximity to magnetic resonance imaging (MRI) scanners, as well as being built directly into buildings and bridges.

Manufacturing FBGs

Fabrication of FBGs benefits from the fact that the core of most optical fibers is doped with germanium (to increase the refractive index), which makes it photosensitive in the ultraviolet (UV). Specifically, photosensitivity means that exposure to UV light will induce a permanent refractive-index change. In some cases, photosensitivity is created or further increased by hydrogen loading.

The most common method for FBG fabrication is to expose a photosensitive fiber to an interference fringe pattern in UV light. This is usually accomplished by directing the output of an excimer laser through a phase mask (essentially a diffraction grating; see Fig. 1). The phase mask diffracts the incident laser light into various orders, which overlap and optically interfere with each other in the mask vicinity. This interference creates stationary, alternating zones of high and low laser intensity whose spacing is either equal to the phase-mask period or half of this value, depending upon the exact exposure geometry.

While this process is conceptually straightforward, in the real world there are several significant barriers to overcome when producing FBGs. The first is cost, specifically of the excimer laser as well as the phase mask. Next is holding and positioning all the components such that a grating having precisely the right spacing and index variation characteristics can be produced at exactly the correct place along the fiber. And, if the goal is to produce a large number of FBGs with each having consistent characteristics, the system must have some way to accommodate the batch-to-batch variations in the index of the optical fiber used.

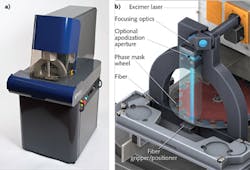

The automated system by Northlab Photonics was developed to meet the need for cost-effective, flexible manufacturing of high-quality, consistent FBGs on a production basis (see Fig. 2). Their NORIA tool integrates a Coherent ExciStar XS excimer laser operating at 193 nm, beam-conditioning optics, up to 16 Ibsen Photonics phase masks (uniform or chirped), automated mechanics, and control software to deliver pushbutton FBG manufacture.For example, the phase masks are all held on a rotating disc to enable switching between fabrication of different FBG types without operator handling. The optical fiber is mounted in a modular fixture and is positioned on a linear stage that allows FBGs to be written along the fiber in a precise position in an automated fashion. Moreover, the total system cost is less than what would be spent to procure all the components individually. Several aspects of how this system delivers operational flexibility and a consistent product merit examination.

Center wavelength accuracy

Probably the single most critical parameter for an FBG is the center wavelength of its reflectance band. This quantity is determined by two parameters: the FBG period (set by the phase mask used), and the effective refractive index of the fiber (which depends upon both the core and cladding index). The effective fiber index can be derived from the fiber numerical aperture (NA), the value of which is specified by the manufacturer for every fiber. Unfortunately, fiber manufacturers don't control core refractive index that tightly, resulting in significant batch-to-batch variations from their specified values, and sometimes even variations within a batch.

Because phase masks are expensive, the goal is to be able to consistently write production FBGs having a fixed target center-wavelength value using just a single phase mask, despite variations in the refractive index of the supplied fiber. The NORIA system accomplishes this by applying a force to physically stretch the fiber during the writing process (called "pretensioning"). When the fiber is subsequently released from this force, it springs back to its original length, thus changing the FBG period. Therefore, adjusting the pretensioning force enables FBGs over a range of periods to be written using the same phase mask.

In practice, the NORIA tool can shift FBG center wavelength as much as 4 nm (for a phase mask nominally centered at 1550 nm) using pretensioning, which is more than twice what is necessary to correct for the typical batch-to-batch variations in fiber NA. Control of the pretensioning force is precise enough to deliver a FBG center wavelength accuracy of 0.1 nm and a repeatability of ±50 pm in production.

Reflectance bandwidth

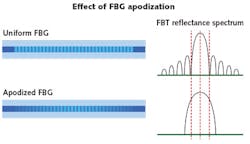

After center wavelength, the next critical FBG properties are typically reflectance bandwidth and the presence of any reflectance peaks outside of the nominal reflectance band (side lobes). The parameters that control reflectance bandwidth are FBG length and the modulation depth of the index changes.

For a grating with a uniform index modulation along its length, reflectance bandwidth narrows as the grating length increases. Unfortunately, the sharper the reflectance peak, the more energy is shunted into side lobes. This effect can be countered by varying the depth of index modulation along the FBG, which is called apodization. However, this does produce some increase in the center reflectance peak bandwidth because it decreases the effective grating length (see Fig. 3).The Coherent Excistar laser outputs a 3 × 6 mm beam that has a uniform (top hat) intensity distribution in the long direction and a Gaussian profile in the shorter dimension. Optics reshape the beam in the NORIA system such that it can write FBGs from 1 to 10 mm in length. The capability for beam apodization is directly built into the NORIA system. This is accomplished by using a shaped aperture in the beam path to convert the uniform distribution of the laser into a Gaussian (or other) profile. Currently, the system is configured with a Gaussian apodization mask that delivers a sidelobe-suppression ratio of at least 15 dB for a 10-mm-long FBG. The company can create custom masks for other configurations on request.

Mechanical stability and positional accuracy

Writing a uniform FBG with a center-wavelength transmission reduction of 20–50 dB might require as many as 1000 of the 5 mJ pulses from the laser. As this laser operates at 500 Hz, this means an exposure time of 2 s. Chirped FBGs (in which the grating period changes along the length of the grating) require much higher refractive-index contrast to reach the same level of reflectance, meaning even longer exposure times. Any relative motion between the phase mask and fiber over this period, even at the nanometer level, is enough to degrade FBG performance. To eliminate any relative vibrational motion in the NORIA system, the fiber is clamped securely during exposure against the phase mask, which is in turn attached to a relatively massive mechanical structure (the "U"-shaped piece seen in Fig. 2).

However, the fiber holding and clamping system must meet another important requirement. For sensing applications in particular, it's not uncommon to write multiple FBGs on a single fiber. Furthermore, the spacing between these individual FBGs must usually be controlled very precisely. But because each FBG is created serially, it is normally difficult to locate it again within 1 mm after it has been written.

The NORIA system utilizes its own clamping and positioning technology to position the fiber relative to phase mask with submicron accuracy. The system also integrates a translation stage that enables multiple FBGs to be written over a total fiber length of 250 mm with a positional accuracy of 0.1 mm. It has not been previously possible to accomplish this task with this level of accuracy and repeatability.

Widespread deployment of FBGs has been limited up until now partially because of the expense and difficulty of device fabrication. The new excimer-laser-based tool can write a single FBG in under 30 s, including fiber positioning, automatic phase-mask selection, exposure, and undocking of the fiber. This should dramatically reduce the unit cost of production FBGs while also delivering the unit-to-unit consistency critical to their successful use in sensing and other applications.

Ralph Delmdahl is product marketing manager at Coherent, Santa Clara CA; e-mail: [email protected]; www.coherent.com. Kristian Buchwald is vice president of the Grating Business Unit, Ibsen Photonics A/S, Farum, Denmark; e-mail: [email protected]; www.ibsenphotonics.com.