FIBERS FOR SENSING: Fiber-optic Fabry-Perot sensors take the strain under high temperature

YUN-JIANG RAO and ZENG-LING RAN

Using a custom-designed 157 nm excimer laser micromachining system, our group at the University of Electronic Science & Technology of China and WuXi ChengDian Optical Fiber Sensing Technology have created a series of novel micro fiber-optic Fabry-Perot interferometric (MFFPI) sensors. Because these micro fiber-optic sensors are directly engraved on silicon or sapphire fibers through formation of high-quality, in-line Fabry-Perot etalons, they have many outstanding advantages such as very small size, self-temperature compensation, high-temperature (>300ºC) survivability, remote-measurement distance capability (>10 km), and are amenable to mass production. These sensors can easily measure strain, pressure, refractive index, temperature, and acceleration in harsh environments.

Under strain

Harsh-environment sensors, especially when temperatures are high, are needed for numerous applications including experimental mechanics, aeronautics, metallurgy, and for downhole oil/gas sensing. However, creating these sensors remains a very challenging mission. The use of electrical sensors in high-temperature environments is greatly confined by the drawbacks of an electrical device such as short lifetime under high temperature, nonlinear distortion, susceptibility to electromagnetic interference (EMI), limited temperature range, and limited measurement distance.1 Fiber-optic sensors can overcome these drawbacks due to their numerous advantages over electrical transducers such as EMI immunity, high temperature tolerance, and longer remote-measurement distances.

Optical fibers used for creating high-temperature sensors are generally silica or sapphire fibers that possess excellent high-temperature stability. Even so, it is still not easy to realize a fiber-optic sensor with good high-temperature performance. Although fiber Bragg grating (FBG) and Fabry-Perot (F-P) interferometric sensors have been successfully commercialized, FBG sensors written by ultraviolet (UV) laser exposures have poor long-term stability at temperatures >300ºC.2 And while temperature-insensitive fiber-optic F-P sensors are considered suitable for high-temperature applications, these devices are typically assembled using multiple optical components easily subject to failure in harsh environments.3-5

To create a successful fiber-optic sensor, three main criteria should be met. First, a qualified high-temperature sensor should be an all-fiber, integrated, monolithic device in a miniaturized format and not constructed by separated components. Since silica or sapphire optical fibers are broadband gap materials, it is very difficult to precisely fabricate all-fiber in-line F-P sensors using conventional means. Second, the device should compensate automatically for a temperature range up to 1000ºC. And finally, the sensor should be mass-producible with good repeatability and low cost—attributes nearly impossible to realize using conventional manual-assembly methods.

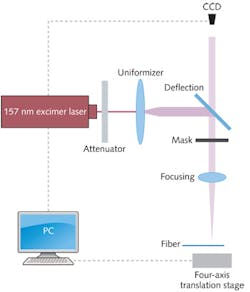

Our team solved these problems by fabricating highly integrated micro F-P sensors on the fiber directly using a custom-designed 157 nm laser micromachining system (see Fig. 1). We found that the optical absorption coefficient at 157 nm has a high value of up to approximately 20000 cm-1, making it possible to achieve high-quality cool machining of silica or sapphire fibers.6 The laser micromachining system consists of a 157 nm pulsed laser, an optical focusing system with 25X demagnification, and a precise translation stage used to mount the fiber to be engraved. The maximum single pulse energy, pulsewidth, and pulse repetition rate of the 157 nm laser was 35 mJ, 15 ns, and 50 Hz, respectively.

Two sensor types

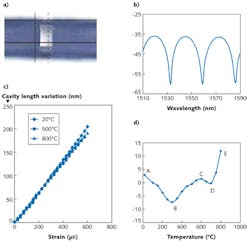

Using the 157 nm micromachining system, the first type of MFFPI sensor is fabricated with a micro-rectangular notch structure inside a silica fiber with a typical size of tens of microns. The 157 nm source light is projected onto the fiber through a rectangular steel mask that is 25 times larger than the notch to be engraved. The notch fabricated inside the fiber forms an F-P interferometric cavity with two smooth and parallel reflective interfaces. An excellent fringe visibility of up to approximately 26 dB was achieved and precise strain measurement under high temperatures up to 800ºC was demonstrated (see Fig. 2).This sensor measures strain by measuring the cavity length variation, given as ε = ΔL/L, where L and ΔL are the real cavity length and variation to original length, respectively. More importantly, this sensor has the unique feature of temperature self-compensation due to the unique cavity structure. The thermal expansion of the fiber core reduces the cavity length since the fiber core is free along the longitudinal direction due to the air gap, while the thermal expansion of the fiber cladding increases the cavity length due to the existence of the cladding that remains after laser ablation. The two effects cancel each other as temperature is varied.

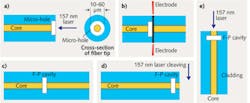

A second type of MFFPI sensor is based on a self-enclosed cavity structure, enabling fabrication of sensors that can measure high temperatures, strain, pressure, and refractive index.7-8 To form the self-enclosed MFFPI cavity, a circular micro-hole with a typical depth and diameter of tens of micrometers is first made at the tip of a cleaved optical fiber via laser micromachining (see Fig. 3).Next, an in-line MFFPI cavity is formed and enclosed by simply splicing the first fiber to another cleaved fiber (that is used as a strain sensor). This micro etalon can be operated at temperatures up to 800ºC due to its robust, stable, and reliable method of fabrication. This device is also insensitive to temperature change due to the hollow-core structure of the etalon and the ultralow thermal expansion coefficient of the silica.

To add pressure, temperature, and refractive-index measurement capability to this sensor, the fiber near the air-filled F-P cavity is cleaved precisely to form a pressure diaphragm (micrometers in size). Because the diaphragm is flat and of almost uniform thickness, its center deflection ΔL, under applied pressure ΔP, can be calculated by ΔL = 3(1 - μ2)R4ΔP/16Eh3,where L, R, and h are the cavity length, radius, and thickness of the diaphragm, respectively; E is Young’s modulus; and μ is Poisson’s ratio.

If cleaving the fiber near the air cavity with a much longer distance (more than 100 µm) to form an intrinsic F-P interferometer, refractive-index and temperature-monitoring sensors can be obtained simultaneously. Basically, there are two cavities: an air cavity and a much longer solid intrinsic F-P interferometer (IFPI). Based on this sensor head, refractive index and temperature can be measured by determining the fringe contrast and optical path difference of the IFPI, respectively.

And finally, the cleaved fiber can be micromachined once again on its endface using a designed mask pattern to form an acceleration sensor (see Fig. 4).9-11 This sensor is sensitive to the acceleration whose direction is perpendicular to the fiber endface due to its double-clamped acceleration-sensing structure. The cavity length variation is driven by the motion of the sensing mechanism induced by acceleration.These F-P sensors have many advantages over conventional fiber-optic sensors including direct formation and easy mass production with low cost, good reproducibility, excellent optical performance, and high temperature stability, making it possible to form a new generation of fiber-optic sensors for numerous applications that accurately measure strain, pressure, acceleration, and refractive index at high temperature.

REFERENCES

1. A.C.R. Grayson et al., Proc. IEEE, 92, 1, 6–21 (2004).

2. Y.J. Rao, Meas. Sci. & Technol., 8, 355 (1997).

3. A.D. Kersey et al., Opt. Comm., 45, 71 (1983).

4. Y.J. Rao, Optical Fiber Technol., 12, 227–237 (2006).

5. T.W. Kao and H.F. Tayler, Opt. Lett., 21, 8, 615–617 (1996).

6. Z.L. Ran et al., Opt. Lett., 32, 21, 3071–3073 (Nov. 1, 2007).

7. Y.-J. Rao et al., Opt. Expr., 15, 22, 14936–14941 (Oct. 29, 2007).

8. Z.L. Ran et al., Opt. Expr., 16, 3, 2252–2263 (2008).

9. Z.L. Ran et al., J. Lightwave Technol., 27, 15, 3143–3149 (Aug. 1, 2009).

10. Z. Ran et al., IEEE Sensors Journal, 11, 5, 1103–1106 (2010).

11. Z. Ran et al., 21st Intl. Conf. on Optical Fiber Sensors (OFS-21), Ottawa, ON, Canada, papers 7753–109, 7753–113, and 7753–114 (May 2011).

Yun-Jiang Rao is director and Zeng-Ling Ran is director assistant of the Key Lab of Optical Fiber Sensing & Communications at the University of Electronic Science & Technology of China, Chengdu, Sichuan 610054 China; e-mail: [email protected]; www.uestc.edu.cn. Rao is also CEO and Ran is CTO of WuXi ChengDian Optical Fiber Sensing Technology Co. Ltd., WuXi, JiangSu, China; www.cdofs.com.