LASER BEAM COMBINING: Beam-combining improvements optimize laser-diode pump sources

D. WILSON, R. DUESTERBERG, L. XU, and J. SKIDMORE

High-power, high-brightness (emitting greater than 3 MW/cm2-sr) fiber-coupled diode pump modules are enabling components for fiber lasers and direct-diode systems, which are targeting industrial applications such as welding, cutting, and etching, as well as medical and graphic arts applications.1 Laser-diode pump sources based on spatially combined single emitters coupled into a common fiber-pigtail output are becoming increasingly attractive due to their higher brightness, efficiency, and small size compared to traditional laser-diode-bar-based systems. For fiber lasers, high-power/brightness diode pumps are advantageous in several ways that include reduced gain-fiber length, reduced number of fiber combiners, smaller footprint, simplified fiber management, elimination of an amplifier stage (in some designs), improved performance, and reduced overall system cost.

Pump platforms based on ensembles of single emitters offer advantages over those derived from monolithic diode arrays due to their high power-conversion efficiency (PCE) and proven diode reliability. Compared to laser bars, advantages of discrete diodes include negligible thermal crosstalk between neighboring emitters and protection against cascading failed emitters. A “green” trend for increasing thermal efficiency is to operate diodes at higher case temperatures, which is more easily realized with distributed architectures due to heat spreading. Finally, the high PCE afforded by distributed architectures also provides for a lower junction temperature, which improves diode reliability.

Beam-combining techniques

While many commercially available fiber lasers continue to deploy single-emitter pumps, advances in single-emitter beam-combination methods have raised the state-of-the-art performance level to 100 W output power from a 105-µm-core fiber. These methods include wavelength, polarization, and spatial beam multiplexing (with the last being most common) or a mixture of these. In spatial beam multiplexing, diodes are stacked into a “staircase” formation so that the output emission can be spatially multiplexed. Each diode typically has a corresponding fast-axis collimating (FAC) and slow-axis collimating (SAC) lens to collimate—and a mirror to point—the emission beam. Collimated output from all emitters is then focused onto the output fiber, which has a matching numerical aperture (NA).

Laser diodes and their associated beam-combining optics have been reported in various configurations that optimize cost per output power (usually stated in dollars per watt), PCE, or footprint, based on optimizing around a specified output power level and brightness while maintaining high reliability.

The total fiber-coupled output power is given by the number of diodes inside the package (N) multiplied by the power per emitter (P) and the coupling efficiency (CE). The total aperture height (h) of the “staircase” inside the package is simply h = N * t, where t is the step height. The fiber NA is defined by application, so the coupling-lens focal length fcl = (h/2)/NA. The fast-axis magnification (My) is chosen to be ≤40 to avoid overfilling the core while remaining below the fiber NA. In the horizontal (slow) axis, the emitter aperture and far-field divergence approximately match the fiber core diameter (105 µm) and NA (0.15), so the slow-axis magnification (Mx) is near unity. Focal lengths of the FAC and SAC lenses are ffacand fsac, respectively. The key formulae are approximated simply as

fcl = (h/2)/NA, where h = N * t (1)

My = fcl/ffac≤40 and Mx = fcl/fsac~1 (2)

Based on the diode near-field and far-field characteristics and other constraints such that acceptable coupling efficiency is achieved, a practical limit of between five to seven diodes can be combined. However, the brightness can be nearly doubled by polarization-beam-combining (PBC) two banks of emitters. For example, IPG Photonics (Oxford, MA) has reported greater than 100 W with 50% PCE into 0.12 NA in a compact form factor.2

High power and brightness at lower cost

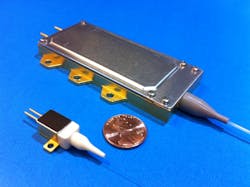

We have developed a high-power pump platform with a 9XX nm (900–1000 nm range) output that produces more than 100 W of optical power from a 105-µm-core, 0.15 NA fiber. When placed next to a standard 10 W single-emitter diode, the compact size of our high-brightness pump is evident (see Fig. 1), as is its spatial efficiency in comparison to that of an array of several single-emitter diodes. Off-the-shelf optical components were selected for the optical train, with the goal of optimizing brightness and PCE while minimizing cost in dollars per watt. The platform was designed to replace ten 10 W single emitters with no penalty in thermal performance.

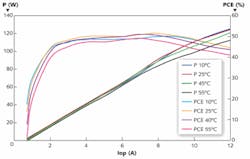

Example data show optical output and PCE versus electrical current for this device operating at a base-plate temperature of 25°C (see Fig. 2). At an operating current of 10 A, 110 W of light at 915 nm is delivered from 0.15 NA fiber with a PCE of 48%.Damaging feedback energy is a pervasive concern for pump modules. Diode pumps at 9XX nm may induce self damage from backreflected high-order modes or from cladding light launched back into the pump source. JDSU first introduced a solution to this problem in 2008 by placing a dichroic filter inside the diode package that only passes 9XX nm light. A similar isolator is incorporated within the high-brightness pump, providing isolation of 30 dB and 25 dB in the 1060–1100 nm and 1050–1150 nm wavelength ranges, respectively.

To achieve maximum module power and brightness, optimizing coupling efficiency into the fiber is critical. Laser-diode divergence parallel to the junction plane typically increases with drive current, thus limiting the power that can be coupled into low-NA fiber. At such high power levels, the limited fiber NA can result in increased risk of overheating the fiber-coating material or other components in or near the optical path. As such, improved package reliability and higher PCE have been enabled by improving the near-field pattern and far-field divergence of multimode laser diodes.3

In many fiber lasers and direct-diode lasers, the pump modules may dominate the bill of materials. Due to their manufacturing and component simplicity, single-emitter pumps have the lowest cost from a strictly dollars-per-watt perspective. However, higher-power modules eliminate many of the subsequent manufacturing challenges that accompany the handling of numerous discrete emitters. For example, because beam combining is performed inside the module, the need for downstream combiners is diminished and the footprint allocated to pumps may decrease considerably.

Innovative beam-combining technologies enable an effective means for approaching higher-power, higher-brightness regime of laser-diode pump modules. Ensembles of single-emitters within a mutual package have been shown to address thermal, reliability, cost, and footprint concerns—providing for an interesting alternative to large arrays of fiber-coupled single-emitter or bar-based higher-power architectures, particularly when targeting direct-diode sources and fiber-laser pumping at kilowatt-class levels.

REFERENCES

1. H. Injeyan and D. Goodno, High-Power Laser Handbook, McGraw-Hill Companies Inc. (2011).

2. V. Gapontsev et al., “High-brightness 9XX-nm pumps with wavelength stabilization,” Proc. SPIE, 7583 (2010).

3. R. Duesterberg et al., “100W high-brightness multi-emitter laser pump,” Proc. SPIE, 7918 (2011).

D. Wilson is product line manager, R. Duesterberg is engineering project manager, L. Xu is senior engineering development manager, and J. Skidmore is director of package development at JDSU, 430 N. McCarthy Blvd., Milpitas, CA 95035; e-mail [email protected]; www.jdsu.com.