Refractive-index Profiling: Transverse interferometry characterizes refractive-index profiles of complex (even multicore) optical fibers

Interfiber Analysis (Sharon, MA) has improved its transverse-interferometry method for nondestructive in situ refractive-index profiling of optical fibers with complex internal structures, and has now commercialized its multifocus tomography technology with its IFA-100 multiwavelength optical fiber analyzer.

Most commercial fiber refractive-index profiling instruments probe the endface of a cleaved fiber and raster-scan its surface to reveal structural information. And while noncontact methods for measuring transversely through the side of an optical fiber have been known for decades, the ability to measure multicore and microstructured optical fibers has been elusive.

Previous tomographic algorithms were intended for nondiffracting beams such as medical x-ray CAT scans and were therefore unsuitable for high-resolution optical microscopy, where the depth of field is made extremely shallow by high-numerical-aperture imaging objective lenses. Interfiber's invention of a new class of multifocus tomographic reconstruction algorithm has enabled the IFA-100 instrument to measure the refractive index of complex structures, including multicore and microstructured optical fibers as well as complex waveguides written into optical fibers by femtosecond lasers.1,2

Transverse interferometry improvements

Measurement begins by placing an optical fiber in the path of an interferometric setup consisting of a spatially and temporally incoherent LED source, a Mach-Zehnder interferometer with high-numerical-aperture imaging objectives, a broadband array detector such as a silicon CCD, and a computer to process the data. The IFA-100 achieves refractive-index measurement accuracy and precision better than ± 0.0001 and spatial resolution better than 1 μm.

Since inventing the original measurement concept, Interfiber Analysis has patented and commercialized the multifocus algorithm for reconstructing the complete two-dimensional (2D) cross-section of complex optical fiber samples from transverse interferograms acquired at a multiplicity of fiber rotation angles. The data acquisition and processing is performed automatically, and makes no assumptions about fiber symmetry or internal structure. Both silica and nonsilica (for example, plastic, fluoride glass, and phosphate glass) fibers can be measured at wavelengths ranging from the ultraviolet through the visible and into the near-infrared.

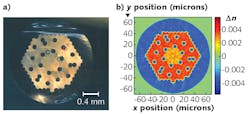

To display 2D cross-sectional refractive-index data, interferograms acquired at multiple rotation angles are coupled with tomographic algorithms to display false-color rendered images (see figure). Three-dimensional (3D) images can also be produced by reconstructing a set of 2D cross-sections at numerous closely spaced axial positions along the fiber length. Such 3D reconstructions are particularly effective for analyzing physical tapers or fusion splices between complex fibers or femtosecond-laser-inscribed waveguides inside such fibers. In addition to multicore fibers, the multifocus approach is effective for microstructured optical fibers such as photonic-crystal fibers and air-core fibers.

REFERENCES

1. See https://goo.gl/9R5g9H.

2. L. A. Fernandes et al., Proc. SPIE, 9740, 97400N (Apr. 1, 2016); doi:10.1117/12.2213597.

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.