OPTICAL FIBER SENSING: Improved sapphire fibers raise prospects for harsh-environment-sensing

The thermal, mechanical, and structural stability of single-crystal sapphire makes it an excellent candidate for optical sensing applications in harsh environments, such as downhole temperature/pressure sensing for the petroleum industry or for use in combustion applications in gas turbines with temperatures greater than 800ºC.

But for sapphire-based optical fibers to be used in harsh-environment temperature, pressure, or dynamics sensing applications, thin-film coatings or external cladding structures must be applied to the sapphire-fiber core to mitigate light transmission losses. Unfortunately, these cladding structures typically cannot withstand high-temperature thermal cycles without losing integrity. Furthermore, it is difficult to find cladding materials or any artificial structures that meet the low-refractive-index requirement and have a low thermal expansion to prevent thermal-stress-induced delamination of the cladding structure from the sapphire fiber surface under high-temperature conditions.

But a new method that uses ion implantation and annealing developed by researchers at the College of Nanoscale Science and Engineering (CNSE) at the University at Albany–SUNY (Albany, NY) is dramatically raising the prospects for using sapphire fibers as photonic sensing devices in harsh environments.

Inducing nanometer-scale voids

To avoid the need for applying a separate cladding material to the sapphire fiber, the ion-implantation and annealing process intrinsically alters the refractive-index profile of the sapphire through structural modifications in the form of nanometer-scale voids (typically 10–20 nm in diameter) that cause a decrease in material density and a subsequent decrease in refractive index of several percent.

The proton-implantation step is performed on either sapphire wafers or sapphire optical fibers. The location and width of the optical-barrier (low-refractive-index) layer formed below the sapphire surface can be controlled by the proton energy. For example, implantation of 1 MeV protons in sapphire results in an optical barrier approximately 10 μm below the surface.

Prism-coupling measurements on a single-crystal sapphire plate processed by proton implantation and thermal annealing at greater than 1000ºC show dips in the reflection curves, indicative of waveguide modes existing in the sapphire plate due to light confinement and propagation in the layer between the sapphire surface and the proton-implanted layer.

For fibers, a proton beam of an appropriate energy is rastered over the fiber surface while the sapphire fiber is continuously rotated about its axis, allowing a continuous, radially symmetric cladding layer to be created in the single-crystal sapphire fiber. Subsequent annealing at temperatures from 600° to 1800ºC can induce refractive-index reductions ranging from 0.5% to nearly 4.0%, respectively.

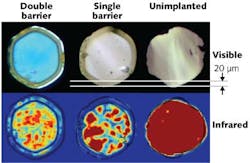

When light is launched into sapphire fibers with cladding made by proton ion implantation and annealing at 1700°C, the resultant cladding structures strongly confine light to the core region of the sapphire fiber in similar fashion to conventional multimode-clad silica fibers (see figure). The research team has also used the method to fabricate a dual-core (or double-cladding) structure in single-crystal sapphire fibers whereby the light propagates in the thin core layer between two proton-implanted layers. This method is promising for production of single-crystal sapphire fibers with only a single or a small number of propagation modes—a crucial requirement for fiber-Bragg-grating (FBG)-based sensing applications.

“The lack of thermally robust cladding and the unavailability of singlemode or even few-mode light propagation due to the difficulty in growing small-sized single-crystal sapphire fiber have been the major hurdles to deploying such optical fibers for sensing applications in harsh environments,” says Mengbing Huang, an associate professor at CNSE, University at Albany–SUNY. “The proton implantation method will provide a viable solution to these problems and help open up new opportunities for harsh-condition fiber-optic sensing.”

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.