Glass multimode fiberoptic links are being considered that can be set up by ordinary consumers for very high-speed home networking (10 Gbit/s and greater). Today’s bend-resistant glass optical fibers are designed for use in data centers and to be handled by professional technicians; to be suitable for use by ordinary people, bend-resistant fibers should be made even tougher than what’s available now. Researchers at Corning (Corning, NY) and Intel (Santa Clara, CA) have come up with a candidate that has a short-term 3 mm minimum bend diameter (for network setup clumsiness) and a seven-year 10 mm bend diameter (for survival afterward).

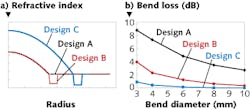

Three designs were considered, two with and one without low-index trenches. The chosen 0.29-numerical-aperture fiber has an 80 μm core diameter, a parabolic graded-index profile, a narrow low-index trench, and a 10 μm cladding, totaling to a mere 100 μm glass diameter (smaller is better for bend resistance). Bend loss for a 3-mm-diameter bend is only about 1 dB. The fiber has a power penalty of about 0.1 ± 0.1 dB at lengths up to 50 m and a bandwidth greater than 800 MHz•km, and is designed to be used in conjunction with inexpensive vertical-cavity surface-emitting lasers (VCSELs) and photodiodes. Contact Paulo Dainese at [email protected].

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.