SPECIALTY FIBER: High-saturation-energy Yb fibers pump up pulsed fiber lasers

MICHEL BÉGIN and BERTRAND MORASSE

New materials processing applications in the industrial, medical, or solar markets require pulsed lasers with high energy and high peak power. To address these new opportunities, changing market conditions have increased the pressure on laser manufacturers to reduce prices and come up with more innovative and cost-effective technologies. As such, fiber lasers have shown great promise over the last few years and are increasingly capturing market share from solid-state and carbon-dioxide (CO2) lasers.

Pulsed fiber lasers for materials processing applications at a wavelength near 1 μm have typically relied on ytterbium (Yb)-doped silica glass. But the design of high-energy pulsed fiber lasers presents many challenges that cannot be easily overcome with traditional Yb-doped optical fibers. Fortunately, high-energy pulsed fiber lasers based on new Yb-doped fibers made from a high-saturation-energy glass matrix solve many of the limitations associated with traditional Yb-doped fibers, while simultaneously offering additional advantages.

Optical fiber considerations for fiber lasers

Silica-based optical fibers are particularly popular as a gain medium because of their excellent beam quality, large heat dissipation, high power handling, and robustness, giving them a significant advantage over traditional gas or crystal-based lasers.

For lasing in the 1 μm window, Yb-doped fibers are used given their high efficiency, high doping concentration, and wide pump absorption band. Furthermore, a double-clad optical fiber (DCOF) configuration allows a large amount of power from low-brightness, high-power pump diodes to be coupled in the DCOF fiber cladding, allowing the high-brightness signal to be amplified to high power levels in a small core with high beam quality. The availability of low-cost and high-brightness fiber-coupled semiconductor pump diodes that emit light in the 0.9–1.0 μm absorption band of Yb DCOF is making the use of fiber lasers even more attractive.

Choosing the best gain fiber to meet performance and cost requirements is of the utmost importance when designing a high-energy/high-peak-power pulsed fiber laser. Due to its long interaction length, a DCOF fiber is prone to nonlinear effects such as stimulated Raman scattering (SRS) and self-phase modulation (SPM) that must be properly managed.1 In a master oscillator power amplifier (MOPA) configuration, the semiconductor seed laser has modes with narrow-wavelength linewidths that can create stimulated Brillouin scattering (SBS) during the amplification process that must be suppressed adequately for reliable system operation.

To reduce these nonlinear effects, the choice of the active fiber is therefore critical. Gain fibers with the following characteristics and corresponding attributes are desirable: high saturation energy for lower pulse deformation and higher nonlinear effect threshold; high pump absorption allowing shorter fiber lengths for higher nonlinear effect threshold; high efficiency for reduced pump power budget and reduced heat-management issues; stable long-term output power to reduce degradation from photodarkening effects; and high-beam-quality output.

Looking at these parameters, one can see that some tradeoffs are necessary. For instance, high saturation energy comes with a larger core diameter that is usually detrimental to beam quality. High absorption can be achieved with either a larger core diameter or by increasing the Yb concentration. The latter, however, typically comes with increased photodarkening effects.

Traditional Yb-doped fibers

At high pulse energy (>50 μJ), pulse deformation can severely limit the desired output pulse shape and create unwanted high peak powers that will lower the nonlinear effect threshold. It is well known that nonlinear effects can be reduced through various pulse-shaping schemes of the seed diode signal. However, arbitrary pulse shapes may be easy to produce at the seed diode level but will be much harder to preserve when amplified at high output energy. When the amplification reaches the saturation energy of the power amplifier, the leading edge of the pulse depletes the gain and there is no amplification left for the remaining part of the pulse.

This phenomenon has been reported in fiber amplifiers by several authors and is due to the saturation energy of a gain medium, which is calculated with the following formula:

where h is the Planck constant, co is the speed of light in vacuum, λo is the wavelength of the signal in vacuum, A is the fiber core area, Γ is the portion of the signal mode profile that overlaps with the Yb ions, and σe and σa are the emission and absorption cross-section at the signal wavelength, respectively.2-6

For a fiber with 20-μm-core diameter operated at 1.06 μm and with an overlap factor near 1, the saturation energy is about 0.15 mJ for a traditional glass fiber. This means that any amplification close to or beyond 0.15 mJ will distort the pulse.

Though fiber amplifiers give excellent beam quality and easy integration, the small core area quickly limits the saturation energy of the system. Not much flexibility is possible for increasing the core area without degrading the beam quality or compromising fiber integration and packaging.

High-saturation-energy glass matrix

Another solution is to lower the cross-section parameters of the gain fiber, which depend on the glass matrix used. The use of a different glass host is particularly attractive since the Yb cross-sections may be up to two times lower than for traditional glass fiber while preserving the excellent mechanical and thermal properties of pure silica glass. It is also noteworthy to mention that the spliceability to standard silica glass fiber is not affected.

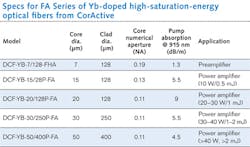

For example, a 20-μm-core fiber may have a saturation energy around 0.35 mJ with a different glass host—more than twice the value obtained with the silica glass used in traditional Yb-doped fibers. Other glass matrices could be used such as germanosilicate or fluoride glass but the photo-induced or mechanical properties are then less attractive. An alternative is the FA series of Yb-doped fibers made from a high-saturation-energy glass matrix, with different core/clad diameters to suit various high-power pulsed fiber laser applications (see table).

Experimental results

A high-energy (40 W), high-power (2 mJ) fiber laser built using CorActive's DCF-YB-30/250P-FA optical fiber employs a 1 W Q-switched fiber laser oscillator seed operating at a repetition rate of 20 kHz and a pulsewidth of 80 ns (see Fig. 1). Although the peak power achieved was 17 kW, the maximum attainable peak power for this fiber could be higher than 40 kW without significant Raman scattering, which is fairly high for a 30-μm-diameter gain fiber. The maximum peak power is dependent on the pumping scheme, pump wavelength, and delivery fiber length, and the power amplifier operates with a slope efficiency of 73% with respect to the launched pump power at 915 nm.Compared to standard optical fibers, high-saturation-energy fibers are inherently more robust against nonlinear effects. As seen on the output spectrum plot, the signal from the 40 W/2 mJ power amplifier shows very little Raman scattering. Other nonlinear effects such as SBS and SPM will also be decreased using high-saturation-energy fibers since most nonlinear effects are directly proportional to the peak power propagating in the fiber. Fibers having a higher saturation energy and lower peak power therefore mitigate these fiber nonlinearities.

Beam quality

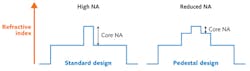

The glass matrix properties of high-saturation-energy fibers tend to create a high numerical aperture (NA)—typically up to 0.20. The NA can, however, be lowered using a pedestal-type fiber design, which consists of adding a raised refractive-index area around the core to decrease the effective NA (see Fig. 2).7,8A pedestal design for high-saturation-energy fibers offers the following advantages: increased doping levels for higher pump absorption; an increased mode area for an increased nonlinear effect threshold; a reduced number of modes for improved beam quality; generation of less amplified stimulated emission to reduce the self-lasing effect; and good spliceability to standard fiber for low-loss (<0.1 dB) splices.

The core NA of high-saturation-energy fibers with a pedestal design is typically decreased to a value near 0.10. But we have found that reducing the NA down to levels of 0.06 is not advantageous. In fact, the use of low-NA, large-mode-area (LMA) fibers (large core diameters and lower core NA) limits the number of supported modes and they are usually operated under tight coiling conditions to eliminate higher-order modes and achieve quasi-singlemode operation.

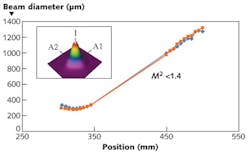

Because this tight fiber coiling is often not highly repeatable and difficult to control in a production environment, high-NA, multimode, high-saturation-energy fibers are preferred to achieve efficient singlemode operation but without unfavorable tight fiber coiling. The singlemode operation is realized by matching the fundamental mode of the high-saturation energy-fiber to the fundamental mode of the delivery fiber.High-saturation-energy Yb-doped glass fibers offer few nonlinear effects, high efficiency, and a low m2 value of less than 1.4 with a Gaussian beam profile, making them an excellent choice for the design of high-energy, high-peak-power fiber lasers (see Fig. 3).

REFERENCES

1. G.P. Agrawal, Nonlinear Fiber Optics, Academic Press, San Diego, CA (2001).

2. K.T. Vu et al., Opt. Exp., 14, 23, 10996–11001 (2006).

3. D.N. Schimpf et al., Opt. Exp., 16, 22, 17637–17646 (2008).

4. M.N. Zervas et al., "High peak power, high rep-rate pulsed fibre laser for marking applications," Proc. SPIE, 6102, 61020Q-1 (2006).

5. F. He et al., Opt. Exp., 14, 26, 12846–12858 (2006).

6. A.E. Siegman, Lasers, University Science Books, Sausalito, CA (1986).

7. P. Laperle et al., "Yb-Doped LMA Triple-Clad Fiber Laser," Proc. SPIE, 6343, 63430X-1 (2006).

8. P. Laperle et al., "Yb-Doped LMA Triple-Clad Fiber for Power Amplifiers," Proc. SPIE, 6453, 645308-1 (2007).

Michel Bégin is a product line manager and Bertand Morasse is an R&D scientist at CorActive, 2700 Jean-Perrin, suite 121, Québec, QC, Canada, G2C 1S9; e-mail: [email protected]; www.coractive.com.