SHIBIN JIANG and PHILIPPE BRAK

Optoelectronics and fiberoptics technology underwent significant advances in the 1990s, driven largely by well-funded innovations in the telecommunications, semiconductor, and consumer-electronics sectors. Although some of these sectors have since lost momentum, the trickle-down effect for smaller photonic application markets has continued and, in some cases, accelerated.

Fiberoptic sensors, for example, have achieved enhanced performance by integrating improvements in fiber, laser, and photodetector technology. At the same time their relative cost has come down, thanks to advances in optoelectronics manufacturing methods (see "Fiber sources streamline lidar").

Optical sensors tend to be smaller and weigh less than electronic devices, but they deliver higher speed, sensitivity, and bandwidth. At the root of these and other advantages is the fact that the sensing and signal-propagation functions rely on photons rather than electrons. This enables a single segmented fiber to form distributed or arrayed sensors that cover extensive locations while conveying the sensed information to a remote station. With small modifications, fiber elements can form many signal-processing devices (such as splitters, combiners, multiplexers, filters, and delay lines), enabling all-fiber measuring systems.

Furthermore, the dielectric glass or plastic materials from which fibers are made makes fiber sensors passive and immune to electromagnetic interference (EMI) so they can perform reliably in close proximity to large electrical equipment such as generators or motors and invite less potential for damage to the sensing element (or remote electronics) if lightning strikes nearby (see Laser Focus World, October 2003, p. 89). Also, because fiberoptic sensors generate neither heat nor sparks, they are safe for operation in hazardous environments such as oil refineries, grain bins, mines, and chemical processing plants. Standard glass fiber loses none of its performance in many corrosive environments or at temperatures reaching 450°F. Special fibers can extend sensor operation beyond 450°F to as high as 1200°F.

Sensor types

Optical fiber is a physical medium so changes in its environment can alter its geometrical (size, shape) and optical (refractive index, mode conversion) profiles. Unlike communication applications, however, which minimize such external influences, fiberoptic sensors deliberately enhance and measure them. The way in which sensors detect such perturbations classifies them as either extrinsic or intrinsic.

In extrinsic devices, the fiber serves as a conduit for transmitting and receiving light at the sensing region. Signal variation occurs outside the fiber, usually within a controlled space. An external environmental change in this space will alter the known parameters of incoming photons.

Intrinsic sensors are all-fiber devices in which external perturbations interact directly with the fiber itself causing some sort of measurable change in the transmitted photonic signal. These sensors are generally more sensitive than external devices and so they are more susceptible to unwanted external perturbations. The all-fiber configuration is more geometrically versatile and simplifies the connection of sensing and transmitting elements. But intrinsic sensors are generally more expensive and less easily multiplexed. They also require more-complex signal-demodulation schemes.

Typical extrinsic sensor applications include linear and angular positioning for aircraft fly-by-light systems or for process control, where they monitor temperature, pressure, liquid level, or flow rate. Intrinsic sensors are used more often to measure rotation, strain, acoustic emissions, and vibration.

Fiberoptic sensors can also be classified by the photonic parameter they modulate/demodulate, ranging from intensity (amplitude), to polarization, phase, or frequency. Most of these configurations derive data from environmental influences or external perturbations at the fiber's sensitized region, which modulates the optical signal by altering one or more of its parameters. Comparing the optical parameters of photons arriving from the sensitized region against those of the original light field provides measurable data.

Intensity or incoherent sensors are simpler to construct, but phase and frequency deliver better sensitivity and resolution. Because detection of phase or frequency relies on interferometric techniques, devices designed for such work are called interferometric sensors. These sensors are typically based on heterodyne detection or coherent detection techniques.

Most current fiberoptic sensors are "point sensors" in which the sensing gauge length is localized to discrete regions, typically requiring a large number of sensors to cover an extended area of interest. Cost, complexity, and fragility of point sensors currently limit the widespread application of these systems. The development of "distributed sensors," capable of sensing continuously over an entire length of fiber, remains a challenge.

Distributed sensors

Most distributed sensors are based on optical time-domain reflectometry (OTDR). The system is probed by a short pulse of optical radiation returned back by reflection. But this technique generally poses a tradeoff between dynamic range and spatial resolution. Shortening the pulses coupled into the fiber and broadening the measurement bandwidth helps improve spatial resolution, but it increases noise level and decreases the dynamic range.

An alternative approach applies coherent frequency-modulated continuous-wave (FMCW) techniques that are well established in radar applications using longer-wavelength radiation. However, optical FMCW techniques modulate the frequency of a laser around its center frequency by coupling part of the light into a reference arm, which plays the role of the local oscillator in a heterodyne coherent detection scheme. A second, longer optical fiber acts as the sensing element.

Reflected light from the sensing region mixes with the light from the local oscillator to generate a beat frequency. The distance information of the sensing fiber derives from measurement of the photocurrent beat frequency using an electrical spectrum analyzer. The distributed reflection of the sensing fiber can simply be Rayleigh backscattering of the optical fiber. Such coherent detection schemes can easily achieve sensitivities down to -100 dB. Also, large dynamic measurement ranges are possible because the photocurrent beat signal is proportional to the square root of the returned laser power and light from the local oscillator helps amplify the backscattered signal.

The principal advantage of FMCW techniques over alternatives like OTDR is its ability to provide spatial resolution on the order of millimeters over a distance of several kilometers. This, however, assumes that the laser source has a long coherence length and a frequency that can be modulated linearly and at high speed. These attributes allow sensing at high spatial resolution with a large measurement range. But they have been largely absent from conventional semiconductor lasers used in fiber sensor applications. Such lasers include both distributed-Bragg-reflector (DBR) and distributed-feedback (DFB) sources in master oscillator-power-amplifier configurations. The DBR lasers, for example, have demonstrated output powers up to 160 mW in a MOPA configuration—but at a cost to the linewidth, which can reach 200 to 500 kHz. Conversely, DFB lasers have delivered narrower linewidths but at outputs limited to 5 mW.

Laser driven

One solution that has elicited interest is fiber lasers that incorporate ytterbium/erbium (Yb/Er) co-doped fiber. This fiber exhibits extremely high optical gain per unit length of up to 5 dB/cm with negligible ion clustering. Its emergence has enabled linear diode-pumped DBR fiber lasers delivering linewidths of 2 kHz, allowing distributed fiber sensors over distances longer than 50 km (as opposed to hundreds of meters demonstrated with conventional DFB sources).

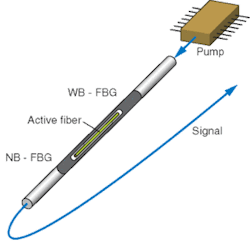

We have developed one such laser that fuses two spectrally narrow fiber Bragg gratings to a very short piece of Yb/Er co-doped fiber (see Fig. 1). This forms a laser cavity with total length of less than 5 cm and frequency stability better than 10 MHz over hours, thermal tuning ranges of 20 GHz, continuous and linear piezo tuning ranges of 100 MHz, and output powers of 150 mW—all of which contribute to reliable and robust sensor systems.

The most obvious potential uses for these lasers are in security, military, and oil-exploration applications in which they would allow cost-effective distributed sensing for monitoring large areas or over long distances with a single laser and photodetector.

One such application is fiberoptic hydrophone sonar arrays (see Fig. 2). For years defense agencies have actively researched sea-bed hydrophone sonar arrays, fiberoptic bottom-mounted arrays, and towed arrays using a combination of time and wavelength-division multiplexing to achieve high channel counts. These arrays also find use for undersea oil exploration and earthquake detection.Substituting interferometric fiberoptic sensors for the conventional electroceramic-based hydrophones in these arrays has several advantages. Besides the benefits of using photons instead of electrons noted previously, fiberoptics help reduce the weight and cross section of cables as well as the through-life cost of the sonar arrays.

The pressure resolution of a fiberoptic-based hydrophone, however, derives from the phase resolution of the sensor's interferometer. Phase resolution, in turn, is adversely influenced by relative intensity noise and frequency noise from the sensor's interferometer. The level of noise increases in proportion to the interferometer's path imbalance, hence a longer interferometer arm means lower pressure resolution.

Narrow-linewidth fiber lasers, such as those described, make excellent sources for hydrophone applications because their frequency noise can be two orders of magnitude lower than the best DFB lasers. The high output power that fiber lasers deliver—without amplifiers—eliminates all spontaneously induced noise.

Shibin Jiang is chief technology officer and Philippe Brak is vice president of sales and marketing at NP Photonics, 9030 South Rita Rd., Suite 120, Tucson, AZ 85747; e-mail: [email protected] and [email protected].

Fiber sources streamline lidar

Coherent lidar systems generally require pulsed-laser systems operating at a single frequency to generate a heterodyne signal for Doppler sensing. These systems, however, are neither compact nor rugged because they incorporate a powerful pulsed-laser oscillator as a slave laser and a stable, but low-power continuous-wave source as the master laser. The system also requires complex controls to enforce and maintain the slave's oscillation at a single frequency.

This conventional configuration for lidar sources demands sensitive free-space optical alignments—not just between the laser resonators, but also at the coupling of seed signals between the master and slave lasers.

Advances in fiber-laser technology have introduced a beneficial alternative to conventional lidar configurations. Fiber sources, for example, are free of alignment error because of their guided-wave nature. Also, erbium-doped fiber lasers operate specifically in the eye-safe 1.55-µm wavelength range, which is not accessible from crystalline solid-state lasers without adding complex nonlinear frequency down-conversion processes. Lidar systems incorporating these sources are both less complex and safer for transmission across public spaces.

Most important, ultracompact Doppler lidar systems have become more feasible with the development of single-frequency, all-fiber Q-switched pulsed lasers. These sources can either operate freely with a local oscillator laser locked passively or actively in frequency, or they can be injection-seeded by the local oscillator laser. The beat frequency of the reference beam from the local oscillator and the returned signal allow simple measurement of the return signal's Doppler shift.

Continuous-wave fiber lasers also make excellent seed lasers, and are highly compatible all-fiber Q-switched sources. Moreover, combining fiber sources allows packaging of a complete lidar system into a small and lightweight box.