Detection of traces of explosive or poisonous gases like methane, hydrogen cyanide, ammonia, or acetylene is sometimes desired in places that are inaccessible or dangerous to humans. Or perhaps one may want to monitor the atmosphere for pollutants. An experimental system described at CLEO 2004 (May 16–21; San Francisco, CA), has the potential to provide a low-cost, compact optical sensor for these applications. Tuomo Ritari of Helsinki University of Technology (Helsinki, Finland) described using photonic-crystal (also known as "holey") fiber with an air cavity at its core to sense gas molecules.1 While a typical spectrometer uses a cell to contain the gas, the "cell" in this device is the core of the fiber, creating a very long interaction length between the guided mode of the light and the gas, while requiring only a small total volume of gas.

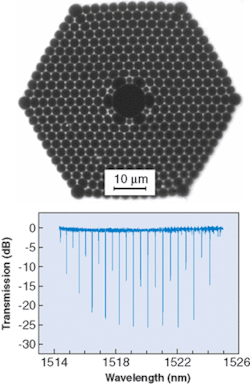

In the experimental setup, light from either a light-emitting diode (LED) or a tunable laser is focused into a vacuum chamber. One end of the 1-m-long holey fiber is placed in the chamber, near the light-input window. The other end of the fiber is spliced to a single-mode fiber connected to an optical spectrum analyzer. The holey fibers tested have core diameters of about 10 and 15 µm.

When a gas at low pressure is introduced into the chamber, it enters the core of the fiber. The light traveling through the fiber is almost entirely confined in the core as well. In addition to the long interaction length, microstructured fibers with air at the core offer higher sensitivity than index-guiding photonic-crystal fibers, explains Ritari, "because more than 99% of the main optical mode is in the air core."

While other groups have experimented with index-guiding fibers, Ritari's group is the first to demonstrate gas sensing using air-core fibers. In addition to Ritari, the group includes Danish researchers with expertise in air-guiding fibers such as Theis Hansen at Crystal Fibre (Birkerød, Denmark). Other group members include Jan Petersen at the Danish Institute of Fundamental Metrology and Thorkild Sørensen and Anders Bjarklev at the Technical University of Denmark (both Lyngby, Denmark), and group leader Hanne Ludvigsen at Helsinki University of Technology (Helsinki, Finland).

Insensitive to bending

The guiding capabilities of the fiber make it highly insensitive to bending, allowing the fiber to be coiled into a relatively compact package. Furthermore, the system is designed to use telecommunications equipment and low-power light sources such as LEDs, creating the potential for these systems to be low-cost sensors.

The researchers measured absorption spectra of hydrogen cyanide and acetylene using light from a 1550-nm LED with a 62-nm full-width at half-maximum bandwidth. They also measured the normalized absorption spectra of acetylene, methane, and ammonia using a tunable laser. While the LED provides a low-powered inexpensive light source, the tunable laser provides higher resolution, which would be useful, for example, in distinguishing the multiple lines in a spectrum (see figure).

Ritari explains that the results show that the sensors can sense strong- and weak-absorbing gases, and that they can obtain increased sensitivity by using longer fiber lengths. "The loss level is quite low," he notes. Alternatively, the 1-m fiber could be used when only a tiny amount of gas is available, because the volume inside the fiber is so small.

One drawback of the system at the moment, says Ritari, is that the light must be transmitted. The group plans to create another version of the sensor that uses Bragg gratings in the fiber to reflect the light. They also plan to improve the system's response time and sensitivity.

REFERENCE

- T. Ritari et al., CLEO 2004, Paper CWM1.