Fine-tuning the properties of optical fiber allows it to meet the specific needs of a diverse range of applications.

Optical fibers have always come in a greater variety than Model Ts, which Henry Ford would gladly sell in any color you wanted, as long as it was black. In the 1950s, the two types of optical fibers were intended for imaging—bundles of loose fibers where flexibility was important, such as gastroscopes; and fused bundles, where high resolution or larger viewing area were critical. The first communication fibers were specialty products in their time. But until the last several years most fibers fell into a few broad classes, optimized for a few types of light transmission.

Fiberoptic fabric art "The River" by artist Laurie Carlson weaves side-emitting plastic fibers and hand-spun flask on a framework of engineered yarns and metal wire. A rotating filter wheel changes the colors through the fiber, producing the striking effect shown in the dark (left). The right photo shows the illuminated fibers and framework in normal light.

Now specialty optical fiber has become a field unto itself, separate from general communications fiber. Some specialty fibers are produced to meet the narrow requirements of specific applications, including sensors and optical amplifiers. Others have their specifications varied so they work better for certain purposes, such as reduced-cladding fibers for coiled-fiber devices, or fibers with cores optimized for use in couplers. The overall goal is moving away from the old "one size fits all" philosophy to custom-tailoring fiber properties for application requirements. That can involve a variety of modifications, including doping fiber cores, controlling polarization, and increasing the core-cladding index differential to reduce bending losses.

Doped fibers

Optical-fiber amplifiers use fibers in which the cores are doped with a light-emitting element such as erbium. An external light source—a semiconductor or solid-state laser—illuminates the fiber, exciting the dopant atoms in the core. An optical signal traveling through the core then stimulates the excited dopant atoms to emit light at the same wavelength, amplifying the signal.

The best-known example is erbium, used in both fiber amplifiers and fiber lasers. The level of erbium doping required depends on the band being amplified and the degree of amplification desired. Erbium absorbs strongly in the 1550-nm amplification band, and attenuation of an erbium-doped fiber at the 1530-nm absorption peak is typically on the order of 10 dBm. Erbium also absorbs strongly on the pump bands at 980 and 1480 nm. The fibers are single-mode, with cutoff wavelengths at 900 to 970 nm for 980-nm pumping and at 1300 to 1450 nm for 1480-nm pumping. Although fluoride fiber amplifiers have been demonstrated, most doped fibers are based on germanium-doped silica.

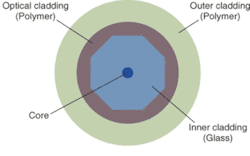

FIGURE 1. Dual-core fiber enhances pump efficiency of fiber laser. The large outer core collects pump light from a large-area source and guides it so it passes back and forth to pump dopant atoms in the inner core. This concentrates the pump intensity and generates a strong population inversion. The small inner core confines stimulated emission to a single mode, generating high intensity.

Other rare earths can be doped into fibers for use as amplifiers and lasers. Important examples are thulium, holmium, ytterbium, and neodymium. Fibers can be made with a dual inner-outer core for high-power fiber lasers (see Fig. 1). The pump light fills the larger outer core, where it is confined by total internal reflection. The outer core is designed to reflect pump light back and forth through the single-mode inner core, where it excites dopant atoms, producing stimulated emission that is guided in the inner core. Codoping with a second element that absorbs pump light, such as erbium, can enhance output.

Fiber Bragg gratings

The composition of photosensitive fibers is adjusted to enhance their response to ultraviolet light for the fabrication of fiber Bragg gratings. Short-wavelength UV light breaks atomic bonds in the germania-doped cores of silica fibers, changing the refractive index by a factor of 0.00001 to 0.001 in standard fibers, depending on the intensity and duration of ultraviolet illumination. Treating the fiber with hydrogen enhances the sensitivity, producing an effect as large as 0.01 (1%), larger than the difference between core and cladding index in most single-mode fibers. Photosensitive fibers have compositions that enhance their response enough to avoid the need for hydrogen treatment.

A phase mask diffracts the UV light illuminating the fiber, producing an interference pattern of alternating light and dark zones along the fiber. The differing UV exposure produces a series of alternating high- and low-index zones in the fiber, which forms a Bragg grating filter. Each refractive-index change reflects a little light, an effect that is magnified by the large number of zones. If the wavelength in the fiber matches twice the grating period, the small reflections add to selectively reflect the light. The effect does not add at other wavelengths—because their phases do not match throughout the grating—and they are transmitted. The grating period can be varied along the length of the fiber to make various types of filters, and for use in sensing.

Sensing and polarization-maintaining fibers

Unlike conventional transmission fibers, sensing fibers are designed specifically to respond to their environment. In general, the goal is to respond strongly to one specific variable, such as temperature or pressure, without responding to others, so designs differ considerably. The most widely used sensor, the fiberoptic gyroscope, requires polarization-maintaining fiber, which also has other applications.

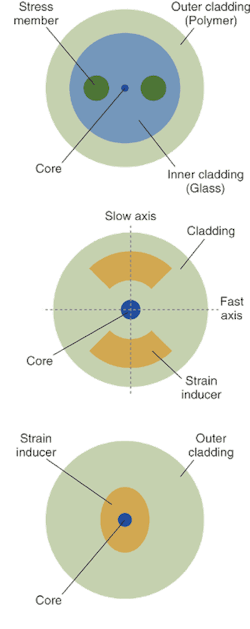

FIGURE 2. Polarization-maintaining fibers have internal structures that strain the fiber across its cross section, separating the two orthogonal polarization modes so light doesn't cross between them. Possible variations include an 80-µm reduced-cladding PANDA design from Fujikura (top), a bow-tie fiber with a wedge design (center), and a dual-core fiber with an oval outer core (bottom).

Standard optical fibers are radially symmetric, so light can easily shift between polarization modes in them. Polarization-maintaining fibers are made with an internal birefringence that effectively isolates light with horizontal and vertical polarization, maintaining the polarization of the input light, as required in certain sensors and other optical devices. Typically this is done by creating an internal structure that applies stress across the fiber in one direction but not the other. In a "PANDA" (polarization maintaining and absorption reducing) fiber, two lobes on either side of the core apply the stress in one direction (see Fig. 2a). The "bow-tie" design is similar, but the lobes on opposite sides of the fiber are wedge-shaped instead of round (see Fig. 2b). An alternate design, with an oval outer core surrounding the inner core, is shown in Fig. 2c.

Most polarization-controlling fibers are polarization-maintaining types. Single-polarization fiber is a different type that guides light with low loss in one polarization mode, but not in the orthogonal mode.

Reduced-cladding fibers

Over the past few years, many companies have begun offering reduced-cladding fiber, single-mode fiber in which the cladding diameter is 80 µm rather than the standard 125 µm. As for 125-µm fiber, the diameter of the protective plastic coating is roughly double that of the cladding. Shrinking the cladding has no significant impact on optical properties because light-guiding in the core does not require a thick cladding. The differences come in mechanical properties.

The 125-µm cladding goes back to the birth of communication fiberoptics, when Corning scientists sought a balance between the cracking and stiffness of thick fibers and the tendency of thin fibers to stick to the spools. They settled on 125 µm as the best compromise, and it remains standard for most applications because the fibers are durable and easy to handle.

However, smaller diameters offer significant advantages when fibers must be densely packed or in coiled fiber devices such as gyroscopes. Thinner fibers can be bent in a tighter radius curve than standard fibers, making them easier to use when fiber pigtails are spliced in tight packages. Thinner fibers also reduce the volume of coiled fiber devices such as fiber gyros and erbium-fiber amplifiers, which depend on the cross-sectional area of the fiber. Erbium-doped fiber for amplifiers, polarization-maintaining fiber for gyros, and fibers optimized for couplers and coupling are all made in reduced-cladding versions.

Coupling and pigtail fibers

Special versions of both standard and reduced-cladding fibers are made for coupling, splicing, and use in devices such as couplers. These applications use relatively short lengths of fiber and have requirements that differ significantly from those for cabled transmission fibers spanning much longer distances. Because distances are short, it's more important to reduce coupling and bending losses than to minimize transmission loss. Thus, coupling and pigtail fibers are designed with a higher-refractive-index core than transmission fibers, giving them a higher numerical aperture, better coupling, and lower bending losses. These fibers are also used in fused fiber couplers, which have similar requirements.

Pigtail fibers may be metal-coated, so they can be soldered in place. They also can be designed for specific wavelengths, such as the 980-nm pump-laser wavelength for erbium amplifiers. Special versions are available with cores designed to couple more efficiently to planar waveguides than standard circular-core fibers. The list could go on and on.

Decorative fibers

Outside of the telecommunications world, special-purpose fibers are also being made for decorative purposes. Conventional plastic fibers have long been used in decorative lamps, collecting light from the source and delivering it to ends that are cut or flared so the large-core fiber sparkles like a tiny cool star. Fibers are used to deliver light in models of buildings and real or imaginary objects—some interesting models are displayed on the web at www.thefiberopticstore.com.

Another decorative twist is production of fiber with light-scattering materials dispersed in the core, which scatter light out the sides so the fiber glows along its length. Some are used to decorate building interiors. Others are woven into decorative fabrics like one made by Cambridge, MA, artist Laurie Carlson ([email protected]; see photo, p. 63).

Outlook

Developers continue to fine-tune fiber properties to meet specific device and application requirements. A quick search reveals a variety of fiber types from high-attenuation fibers for use in attenuators to special fibers to couple 980-nm pump diodes to erbium-doped fiber amplifiers. Fiber-Bragg gratings are specialty fibers that come in many variations. Several other fibers are sometimes considered specialty products, including dispersion-compensating fibers, mid-infrared fibers, plastic fibers, UV fibers, and large-core silica fibers for laser beam delivery.

The most intriguing developments lie in the realm of photonic-crystal and photonic-bandgap fibers. These microstructured fibers can be made with single-mode cores much larger—or much smaller—than conventional fibers. Fibers with tiny cores have very high nonlinearity, attractive for building nonlinear devices. Hollow-core fibers can offer very low dispersion and attenuation—or could be filled with fluids that alter their properties further. Microstructures offer new ways to engineer fiber dispersion. Watch the research papers for more new variations.