Optical fibers containing fiber Bragg gratings (FBGs) are extensively used for remote sensing. Temperature or mechanical strain on a remotely placed FBG grating in a long fiber changes the FBG’s period and thus shifts its center wavelength; this shift can be as small as 1 pm for some very sensitive applications. Multiple FBGs along the fiber allow sensing at many different points. However, the spectrometer or swept-laser-based wavelength interrogators used to sense these wavelength shifts are complex and expensive.

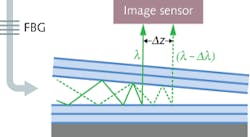

A simple, integrated system for wavelength interrogation of FBG sensors has been developed by a researchers at the U. of Alberta (Edmonton, AB, Canada). In their approach, they used a tapered waveguide clad with omnidirectional Bragg reflector claddings to serve as bandpass filters. The dispersion within the tapered waveguides themselves causes lights of different wavelengths to be coupled through claddings at different positions along the waveguide. An image sensor detects the light’s position shift from a particular FBG sensor when its wavelength changes. A single tapered waveguide can be used for interrogating multiple FBGs along a fiber, and multiple tapered waveguides, fabricated closely side-by-side, can interrogate multiple FBGs from multiple fibers, all using the same image sensor. The experimental device was clad by silicon/silica (Si/SiO2)-based Bragg mirrors and was imaged by a microscope onto an indium gallium arsenide (InGaAs)-based infrared camera. Wavelength shifts down to 10 pm were resolved with a peak-detection algorithm. Reference: C. Potts et al., Opt. Lett. (2014); http://dx.doi.org/10.1364/ OL.39.005941.

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.