Microstructured Fibers: Superdots enhance microstructured-fiber properties and remote-sensing capabilities

ERIK SCHARTNER, HEIKE EBENDORFF-HEIDEPRIEM, and TANYA MONRO

Significant progress has been made in the field of optical fiber sensing, which allows measurements to be performed in difficult-to-reach places where conventional sensors are not possible due to their electrical interference or the requirement for large sampling volumes. Careful exploitation of the properties of the fibers enables biosensing, chemical sensing, or the measurement of physical sample parameters.1

The primary focus of fiber-sensing work over the preceding decades has been in structural health monitoring wherein fibers are embedded within structures to monitor stress and strain through the use of Bragg gratings. These systems, as well as the telecommunications networks most commonly associated with optical fibers, rely primarily on the lack of interaction between the light guided within the fiber core and its external environment in order to minimize optical losses over the length of the fiber.

Some sensing applications, however, look to subvert this property and instead seek interaction between the light guided in the fiber and the external environment. Tapering fibers down to very small dimensions (<1 μm diameter) is one possible solution that can allow this interaction to occur.2 As the dimensions of the tapered fiber are reduced, the light progresses from being guided solely within the glass to being guided external to the glass, resulting in a very strong interaction between the guided light and the external environment.

While these tapers allow a large interaction, they are limited in manufacturing length and handling practicality. With such small dimensions, they are easily degraded or destroyed by dust or physical contact.

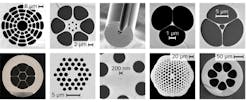

One solution to these issues is a suspended-fiber-nanowire configuration in which the nanowire or tapered fiber is encased within another optical fiber with a larger glass jacket such that light interaction with the external environment can still occur while protecting the nanowire from damage.3 This final geometry then possesses a small core surrounded by three to four air voids into which liquid or gas samples can be filled. These voids are large enough such that liquids can fill to depths of ~20 cm within three to four minutes, but small enough such that the total sample volumes required to perform a measurement can be as small as 10–20 nL.

Extrusion technique

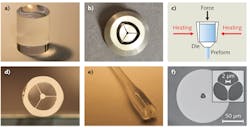

Microstructured fibers with voids can be fabricated using stacked optical fibers or by ultrasonic drilling directly into the initial glass rod preform. However, these methods are typically limited in terms of the final geometry to circular features created by stacked rods or drilled circular holes.3 An alternative to these methods is called the extrusion technique, in which almost arbitrary features can be fabricated in the initial fiber preform in a single step (see Fig. 1).4

Extrusion involves fabrication of a metal or ceramic die with the desired final structure on the output face of the die. This geometry is essentially a scaled-up version (10–20 mm in size) of the final desired geometry. A glass billet is then heated beyond its softening point and forced through the die. By controlling the temperature and the force during this process, the emergent preform displays uniform dimensions along its length and can then be drawn down into the fiber using standard methods (see Fig. 2).Soft glasses

Extrusion techniques are currently limited by the maximum temperature that can be obtained during the extrusion process, which restricts the material choice. Materials must be chosen with a softening point that is low enough to preclude deformation of the die. A standard die made from steel, for example, prevents the use of silica glass-the most common material for the manufacture of optical fibers. Fortunately, there are numerous die choices to cover a range of polymer and glass materials.

Most of the glasses suitable for extrusion fall under the broad category of soft glasses that melt at a lower temperature than conventional glasses. In addition to their lower melting point, these glasses typically have a higher refractive index and nonlinear refractive index than standard glasses, allowing them to be used in applications such as all-optical switching and supercontinuum generation.5

This high nonlinear refractive index, combined with the almost arbitrary control over the fiber geometry, allows these extruded microstructured fibers to be customized for a desired application. This high refractive index also allows sensing in liquids whose refractive index is equal to or higher than that of silica glass, wherein the light would usually be stripped from the core by the high-index liquids.

Suspended-care fiber sensing

Previous work with suspended-core fibers has mainly looked at sensing for various chemicals through the use of fluorescent dyes. The fluorophore is chosen to react with the desired target of interest, resulting in an increase or decrease in the fluorescence signal. By monitoring the change in fluorescence, the detected signal intensity can then be correlated to the quantity of the fluorophore present.

Fluorophores can be combined with suspended-core fibers either by directly filling the mixed solution into the voids along the length of the fiber, or alternatively, by attaching the fluorophore to the internal walls of the fiber using covalent or electrostatic attachment methods. This newly functionalized fiber can then be dipped directly into the sample, which fills up into the length of the fiber via capillary action.

Biosensing is performed similarly by attaching fluorophores to antibodies used as fluorescent labels. Generally the labels used are standard organic fluorophores that suffer from photobleaching and autofluorescence background levels from the sample. To circumvent these issues, alternative fluorescent labels such as quantum dots have found extensive use in biophotonic applications because they are considerably more photostable than organic dyes.

Nanocrystal labels

Nanocrystal labels doped with rare-earth ions such as erbium, thulium, or ytterbium can be excited using near-infrared sources and produce visible light through upconversion processes. By carefully controlling the synthesis process, these nanocrystals can be fabricated with a relatively uniform size distribution and through further processing can then be attached to antibodies for use as fluorescent labels.

Nanocrystals are both immune to photobleaching and, due to infrared excitation, are subject to almost no background autofluorescence from the sample. The combination of nanocrystals and suspended-core optical fibers allows sample measurements to be performed at concentrations that are orders of magnitude lower than when using quantum dots alone (see Fig. 3).6Microstructured fibers can be used to optimize nanocrystalsensing performance through characterization of the nanocrystal behavior over a large range of excitation powers and optimization of light emission as the dopant concentration is changed. If thulium:ytterbium nanocrystals are doped with particularly high concentrations of thulium, for example, the nanocrystal emission can be further intensified.7 These bright nanocrystals or Superdots incorporate thousands of emitters per nanocrystal, significantly increasing the signal produced per nanocrystal to increase the signal-to-noise ratio for low-concentration measurements.

Developed by Dayong Jin's group at the Advanced Cytometry Labs at Macquarie University in collaboration with researchers at Peking University and the University of Adelaide, these Superdots greatly increase the number of photons that can be generated per nanocrystal. Combining the Superdots with suspended-core microstructured fibers allows the detection of a single nanocrystal in solution, as the signal generated from one Superdot can be recaptured into guided modes within the optical fiber and measured on a detector. This is the first demonstration of single-particle detection at one end of an optical fiber from the other end-an important step towards in vivo measurements.

With this remote-sensing capability, microstructured fibers and Superdots could allow sensing within the living human brain, next to a developing embryo, or within an artery, locations inaccessible to conventional measurement tools. This paves the way to numerous breakthroughs in medical treatment such as measuring a cell's reaction in real time to a cancer drug, revealing when the treatment has been delivered, and whether or not a person is responding to the therapy.

References

1. T. M. Monro, et al., Opt. Fiber Technol. 16, 6, 343-356 (2010).

2. L. Tong, et al., Nature 426, 6968, 816-819 (2003).

3. H. Ebendorff-Heidepriem, et al., Opt. Express 14, 4, 2646-2657 (2009).

4. H. Ebendorff-Heidepriem, T. M. Monro, et al., Opt. Express 15, 23, 15086-15092 (2007).

5. W. Q. Zhang, et al., Opt. Lett. 36, 4, 588-590 (2011).

6. E. P. Schartner, et al., Nanoscale 4, 23, 7448-7451 (2012).

7. J. Zhao, et al., Nat. Nanotechnol. 8, 10, 729-734 (2013).

Erik Schartner is a postdoctoral researcher in the School of Chemistry and Physics and Institute for Photonics & Advanced Sensing (IPAS) at the U. of Adelaide, Adelaide, South Australia 5005, Australia; email: [email protected]; www.adelaide.edu.au. Prof. Tanya Monro is an ARC Georgina Sweet Laureate fellow and IPAS director. Prof. Heike Ebendorff-Heidepriem is senior research fellow and one of the leaders of the Optical Materials and Structures Theme at IPAS.