BALTIMORE, MD--It was a battle of the fiber lasers at the post-deadline session at CLEO `97. First up was Martin Muendel from Polaroid Corp. (Cambridge, MA), who discussed a double-clad ytterbium-doped silica fiber laser (post-deadline paper CPD30-1). Using four 915-nm fiber-coupled diode bars, researchers from Polaroid pumped a laser fiber with 55.4 W to produce a pump-limited output of 35.5 W at 1100 nm, or 140 MW/cm2 peak in the core. There was no damage or output instability, or other fiber-related power limitations.

According to Muendel, this result was the highest CW output from a fiber laser reported to date. Future work includes higher power generation by using brighter pumps—such as a 40-W laser from Opto Power Corp. (Tucson, AZ)—pulsed operation to produce 30-µJ pulses at 1 MHz repetition rate, and frequency doubling to cover the wavelength range from 525 to 575 nm. "This could open a whole new arena of applications," says Muendel.

Second up was Daryl Inniss from Bell Labs- Lucent Technologies (Murray Hill, NJ), who described a single-mode Yb-doped cladding-pumped fiber laser emitting from 1.065 to 1.472 µm (paper CPD31-2). The Yb-doped fiber cavities were defined by two fiber Bragg gratings. Output power generated from this system was 16.4 W at 1065 nm and 20.4 W at 1101 nm.

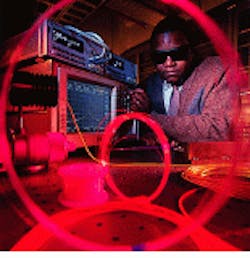

Inniss also reported on the construction of a cascaded Raman fiber laser with an output power of 8.5 W at 1472 nm (see photo). The Lucent fiber laser was pumped by a single Opto Power 915-nm, 1-cm-wide high-power semiconductor laser bar in a specially designed beam-shaper configuration for optimal fiber coupling. "This allows us to capture more light, enabling higher powers," says Inniss.

According to Inniss, the key to high power was the double-clad structure. Because of this, the researchers did not have to worry about coupling single-mode light into a single-mode fiber, which is the industry standard.

In a smooth transition, Inniss acknowledged the differences between the Polaroid fiber laser system and the Lucent Technologies system. Inniss says that although the Polaroid system demonstrated a higher output, it requires four diode lasers, while the Lucent system uses only one. Also, the Polaroid laser could not be used to pump a cascaded Raman laser unless it was coupled with a conventional single-mode fiber. In addition, Inniss says, the Lucent system allows greater wavelength flexibility. "In principle, the ytterbium-doped lasers can operate at any wavelength from 1050 to 1140 nm," says Inniss.

Fiber lasers have potential applications in telecommunications, materials processing, printer, and medical fields.

About the Author

Laurie Ann Peach

Assistant Editor, Technology

Laurie Ann Peach was Assistant Editor, Technology at Laser Focus World.