In the early days of the laser industry, the best way to reach high powers was to extract energy from a large volume of laser material. That’s still the case for some purposes, such as assembling large glass amplifiers to deliver 1.8 MJ pulses from the National Ignition Facility at the Lawrence Livermore National Laboratory. But for many industrial applications, the high-power laser medium of choice has become an optical fiber with an ytterbium-doped core.

Fiber-laser powers have come a long way since Elias Snitzer made the first one in 1963. In June IPG Photonics (Oxford, MA) reported continuous-wave single- mode output of 10 kW at Laser 2009 in Munich and at the Solid State and Diode Laser conference held by the Directed Energy Professional Society (DEPS) in Newton, MA. IPG has also built a 50 kW multimode fiber laser, which Bill Shiner, vice president for industrial markets, says Raytheon (Waltham, MA) has tested for potential weapons applications. But IPG’s bread-and-butter business is industrial materials-working, from cutting silicon wafers for solar cells to robotic welding of metal sheets.

Why fibers for high power?

Like other diode-pumped lasers, fiber lasers essentially convert the raw low-quality pump laser output into a much higher-quality laser beam that can be used in applications from medicine and materials-working to weapons. The fiber geometry has two important advantages for high-power operation: efficient conversion of pump power into output in a high-quality beam, and good dissipation of the inevitable waste heat.

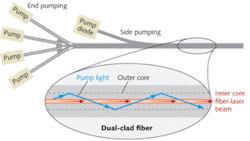

The high efficiency comes from diode pumping, careful choice of the active laser species, and optimization of fiber design. The fibers used in high-power fiber lasers have an inner core containing the laser species, and an outer core that confines the pump light, a more recent Snitzer invention. The pump light can enter the outer core through the end of the fiber or by being coupled through the side of the fiber in a direction nearly parallel to the fiber axis (see Fig. 1). The latter approach is called “side pumping,” but does not mean the pumping is transverse to the laser cavity, as in bulk lasers. Once guided within the outer core, the pump light passes repeatedly through the inner core as it travels the length of the fiber, giving high pumping efficiency. Stimulated emission is guided inside the inner core, building to high intensities before it emerges as a laser beam.

The active species in most fiber lasers is ytterbium, chosen because the small quantum defect–the difference between energy of pump and output photons–is only about 6% when pumping a 1035 nm Yb-fiber laser on its 975 nm absorption line. In contrast, the quantum defect of a 1064 nm neodymium laser pumped on its 808 nm absorption line is 20%. The small quantum defect helps allow optical-to-optical pumping efficiency to exceed 60% for ytterbium-fiber lasers. With electrical-to-optical conversion efficiency of 50% for pump diodes, that means wall-plug efficiency can reach 30%.

Fiber geometry exposes a large surface area per unit volume, aiding cooling of fiber lasers, but even with water cooling, heat dissipation can limit performance. Five years ago developers had hoped that increasing dopant level and size of the inner core could allow fiber lasers to reach higher powers, but Johan Nilsson of the University of Southampton says that at high average powers “thermal effects come back to kill you” because residual heat becomes harder to remove from the fiber.

Single- and multimode fiber lasers

Traditionally fiber lasers have been pumped directly with diode lasers, but the limited brightness of 980 nm pump diodes restricts high-power Yb-fiber lasers to generating kilowatt-class output, Oleg Shkurikin of IPG told the DEPS meeting. The key to obtaining higher powers from Yb-fiber amplifiers or lasers is to switch to brighter pump sources, such as Yb-fiber lasers emitting at 1018 nm. Yb-fiber absorption at 1018 nm is an order of magnitude below that at the 975 nm absorption peak, but the 1018 nm fiber laser is 100 times brighter.

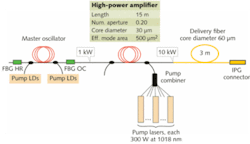

“Both approaches are viable,” Shkurikin said, but there are tradeoffs. Direct diode pumping provides efficiency up to 35% and permits smaller devices, but results in higher heat loads per unit length of fiber, and single-fiber versions with gigahertz laser bandwidth now are limited to output of 400 to 600 W. Erbium-fiber laser pumping reduces efficiency to 25% to 28% and roughly doubles the size of the laser package, but now offers total power of 1 to 1.5 kW from a single fiber.Higher-power out with good beam quality can be generated by combining the outputs of many single-mode Yb-fiber laser modules in a 2.5 m output fiber with 100 µm core. At the DEPS, Alex Yusin of IPG reported obtaining just above 10 kW in a beam with M2 below 1.3, an impressive jump from the 5 kW achieved in 2008. IPG hopes to have a commercial version ready by year-end. “It will be very difficult to get to 15 or 20 kW, but we hope to by 2010 or 2011,” he added. The system draws 40 kW of power, and is refrigerator-size (see Fig. 2).

Reaching that power required an oscillator-amplifier configuration and a two-stage pumping process. First 975 nm diodes pumped Yb-fiber lasers emitting at 1018 nm, which then pumped Yb-fiber lasers emitting at the 1070 nm output wavelength. That reduced heat dissipation in the 1070 nm Yb-fiber laser, and the good beam quality of the 1018 nm pump reduced divergence of the 1070 nm output.

Producing higher powers comes at a steep cost in beam quality. Yusin said IPG’s 50 kW laser has a beam quality M2 of 33, although with 170 kW of power needed to generate the multimode beam, its wall-plug efficiency is higher than the single-mode laser. The output comes from combining the beams from an array of 1.1 kW modules in a single length of 200 µm core output fiber. The whole system is about the size of three large refrigerators (see Fig. 3).Eye-safe fiber lasers

One important drawback of Yb-fiber lasers is that their output poses a serious retinal hazard. That concerns military planners because they don’t want to expose troops or noncombatants to dangerous beams during training exercises or cause collateral damage during military operations.

Operating at wavelengths longer than 1.4 µm increases the safety margin for retinal damage by a factor of between 100 and 1000, Josh Rothenberg of Northrop Grumman Aerospace Systems (Redondo Beach, CA) told the DEPS meeting. Air transmits the 1.55 µm wavelength of standard erbium-fiber lasers quite well, but diode pumping is inefficient. He thinks thulium (Tm)-doped fiber lasers emitting near 2 µm are more attractive because a single 790 nm pump photon can excite two thulium atoms to the upper laser level, doubling quantum efficiency from 40% to 80%.

He reported that Northrop Grumman reached single-mode output of 608 W from a Tm-fiber system with 5 MHz linewidth at 2040 nm. A 3 mW distributed-feedback oscillator and a series of preamplifiers were followed by the main amplifier, a 3.1 m length of dual-clad Tm-doped fiber with 25 µm inner core and 400 µm cladding. Pump power absorbed in the amplifier was 1.1 kW. Rothenberg reported M2 of 1.05 for the full 608 W beam, with more than 98% of the power confined to the core, “all very favorable for coherent combination” of multiple fiber-amplifier outputs to deliver even higher powers.

A different approach to erbium pumping could be promising, said Mark Dubinskii of the U.S. Army Research Laboratory in Adelphi, MD. Instead of pumping at the usual 980 nm line, he tried pumping erbium at 1530 nm to excite emission at 1600 nm, a quantum defect of only about 4%. Corning demonstrated the idea in 2003, but only reached 500 mW from a double-ended laser. Dubinskii generated 45 to 50 W of pure single-mode output at 1580 nm when pumped with a 100 W narrowband source at 1532.5 nm–85 W of which were absorbed. “We expect to get to 6 kW before reaching nonlinearity limits,” he said.

Single-fiber limits and beam combination

Nonlinearities are one of the inherent limitations of the fiber form. The most important is stimulated Brillouin scattering, which scatters light propagating through a fiber in the reverse direction, effectively limiting the maximum power transmission. The effect is strongest for light concentrated in a bandwidth smaller than the Brillouin bandwidth of the material, tens of megahertz for silica, where it limits power from a single-mode fiber to hundreds of watts.1 Increasing bandwidth to gigahertz or tens of gigahertz allows higher power, but eventually optical damage and other effects limit power.

Combining beams from a number of single-mode fiber lasers is an obvious route to higher power, but the question is how to do it (see www.laserfocusworld.com/articles/332972). Coherent beam combination is attractive in theory, but has been tougher in practice; phase-matching the sources stably enough for constructive interference among the beams requires active feedback control. Nilsson says a promising approach is a synthetic phase-matching approach developed by Thomas Shay of the Air Force Research Laboratory (Kirtland AFB, NM).2

So far, incoherent phase combination is ahead in output power. IPG uses spatial beam combination, tiling fiber-laser beams across the input end of a multimode beam-delivery fiber. Another approach is spectral beam combination, which overlays beams at different wavelengths, in a high-power version of wavelength-division multiplexing.3

Raw power is far from the only story. Nilsson is working on wavelength conversion and Raman fiber lasers. Others are working on ultrafast fiber lasers, which Photonic Frontiers will cover in February.

References:

- S. Gray et al., IEEE J. Sel. Topics in Quant. Elect. 15, p. 37 (Jan/Feb 2009).

- T. M. Shay et al., IEEE J. Sel. Topics in Quant. Elect. 13, p. 480 (May-Jun 2007).

- T. Schreiber et al., IEEE J. Sel. Topics in Quant. Elect. 15, p. 354 (March/April 2009).

Jeff Hecht | Contributing Editor

Jeff Hecht is a regular contributing editor to Laser Focus World and has been covering the laser industry for 35 years. A prolific book author, Jeff's published works include “Understanding Fiber Optics,” “Understanding Lasers,” “The Laser Guidebook,” and “Beam Weapons: The Next Arms Race.” He also has written books on the histories of lasers and fiber optics, including “City of Light: The Story of Fiber Optics,” and “Beam: The Race to Make the Laser.” Find out more at jeffhecht.com.