Microstructured Fibers: Butterfly microstructured fiber complements FBG-based sensing

THOMAS GEERNAERT, FRANCIS BERGHMANS, and HUGO THIENPONT

A microstructured optical fiber (MOF) is an optical fiber that has a transverse wavelength-scale microstructure that typically consists of air holes running along the entire length of the waveguide. These MOFs—also referred to as photonic crystal fibers or PCFs—emerged in the 1990s as a new family of optical waveguides that promised to feature unprecedented properties. Indeed, they have been the subject of numerous research and development efforts and have fulfilled many of their promises.1

The best-known MOF examples include highly nonlinear fibers for octave-spanning supercontinuum generation, large-mode-area fibers for high-power fiber lasers, and dispersion-compensating fibers in optical telecommunications. More recently, microstructured optical fibers are finding utility in biomedical sensing and even structural health monitoring.2 Their success results from the great flexibility that MOFs offer in terms of tailoring their optical waveguide properties and adapting these properties to suit a wide range of applications.

FBG limitations

Since the holey microstructure also affects the mechanical properties of the MOF, and therefore its optomechanical response to mechanical and thermal perturbations, this technology provides opportunities to overcome some of the long-standing limitations of existing optical-fiber-based mechanical sensors-in particular, fiber Bragg grating (FBG) sensors.

A FBG is a wavelength-selective filter fabricated inside the core of an optical fiber for which the reflected wavelength changes when submitted to mechanical strain and/or temperature changes.3 Although FBG-based sensors have many advantages such as low weight, small size, immunity to electromagnetic interference, and high linearity of the measured response, they still have a number of shortcomings. For example, a FBG fabricated in a conventional step-index optical fiber is sensitive to both temperature changes and axial strain leading to cross-sensitivity issues. Furthermore, the sensitivity of FBGs in conventional optical fiber to transverse strain remains considerably lower than to axial strain, while monitoring transverse strains is most important in many applications.

Butterfly MOFBGs

The fabrication of FBGs in MOFs has been an intense area of research over the past decade. At first, conventional ultraviolet-based grating inscription techniques performed poorly. But today, the use of dedicated microstructures or adapted inscription setups that rely, for example, on femtosecond multiphoton inscription, allow the fabrication of FBGs in MOFs with a high spectral quality. The availability of such devices further leverages the application potential of both MOF- and FBG-based technologies.4

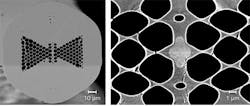

To illustrate ease of fabrication, we focus on a highly birefringent single-mode MOF with a high mechanical anisotropy that we have specifically developed for pressure and transverse strain measurements (see Fig. 1). This MOF has a relatively large birefringence on the order of 10-3 and therefore guides two orthogonally polarized modes. Because of the specific shape of the microstructure we refer to this fiber as the "butterfly MOF". The central part of the core region is doped with germanium oxide (GeO2) to allow for the inscription of FBGs using conventional ultraviolet grating writing techniques.5

A Bragg grating inscribed in this MOF yields two Bragg reflection peaks corresponding to each of the orthogonally polarized guided modes. The spectral distance or wavelength separation between those peaks—denoted by Δλ—is linked with the MOF's modal birefringence.

Owing to the mechanical asymmetry of the fiber's cross-section, hydrostatic pressure or a transverse mechanical load induces material birefringence via the stress-optic effect and is therefore encoded in Δλ. The Bragg peaks will then move towards or away from each other in this microstructured optical fiber Bragg grating (MOFBG) device. On the other hand, Δλ is practically insensitive to temperature and to longitudinal strain.6

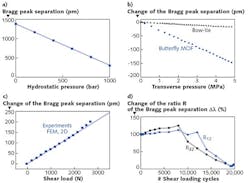

The butterfly MOFBG's working principle is most clearly illustrated when tested under hydrostatic pressure P and considering Δλ as the sensor signal. Both negative (dΔλ /dP < 0; the peak separation decreases with pressure) and positive (dΔλ /dP > 0; the peak separation increases with pressure) pressure sensitivities can be obtained by controlling the fabrication process of the MOF and thereby the resulting microstructure deformations and air filling factor in the core region.7

For different butterfly configurations, we obtained experimental sensitivities of -15 pm/MPa and +33 pm/MPa with excellent linearity for pressure values up to 1000 bar. These values are more than 20 times larger than in conventional birefringent optical fibers. In addition, such pressure measurements benefit from the low sensitivity to temperature (expressed as dΔλ /dT) that is below 0.02 pm/°C.

Structural health monitoring

Besides hydrostatic pressure monitoring, the high transverse strain sensitivity of the butterfly MOFBG enables multiaxial strain measurements in composite materials with unprecedented strain resolution.

A substantial amount of research has already been conducted on optical fiber sensor techniques for monitoring the structural integrity of fiber-reinforced polymers. Optical fibers are minimally intrusive when embedded and offer accurate quasi-distributed strain measurements when multiplexed. The integration of multiaxial strain FBG sensors within such a material provides useful information about the strain state of the host material to support structural health monitoring, for example, of composite material structures used to build aircraft.

The limited transverse strain sensitivity of conventional fibers makes it difficult to realize multiaxial strain sensing, but with the butterfly MOFBG, 3D strain sensing becomes possible.8

Due to the asymmetry of its microstructure, the sensitivity of the butterfly MOFBG to transverse strain varies in a sinusoidal manner with the angular orientation of the microstructure with respect to the direction of the applied load. This dependence can be exploited to quantify the strain along the three directions of space inside a carbon fiber reinforced polymer (CFRP) composite material.

To demonstrate CFRP 3D strain, we embed two identical MOFBG sensors parallel to each other, but with different angular orientations of their microstructure with respect to the through-the-thickness direction of the composite laminate. The maximum difference in transverse strain sensitivity is obtained when combining angular orientations of 0° and 90°. The normal strains in the 3 directions of space in the composite material can then be measured via the changes in the four Bragg wavelengths returned by two closely spaced parallel MOFBG sensors.

The butterfly MOFBG sensor configuration exhibits a 6X higher mathematical stability and a 6X improved strain resolution in the transverse direction compared to traditional FBG-based optical fibers. Using commercially available FBG interrogators with a Bragg peak detection resolution of 1 pm, the transverse strains can be measured with a resolution of 5 με.

In addition, the butterfly MOFBG enables shear strain measurements in glued joints. Such glued joints are becoming increasingly popular as a fastening and repair technology, but in situ monitoring of the quality and strength of adhesive bonds has proven very difficult. Our MOFBGs provide a solution to that issue. By embedding these sensors in the adhesive bond with an angular orientation of 45° such that the transverse strain sensing axes of the MOF are aligned with the directions of principal stress, we can measure shear load in a single lap adhesive joint (SLJ).9

Using our MOFBGs to measure SLJ shear load, we obtained a shear stress sensitivity of about 67 pm/MPa, which corresponds to a shear strain sensitivity of 10 pm/mε (see Fig. 2). This is a 4X improvement over the sensitivity of conventional birefringent optical fibers.The combination of multiple shear stress sensors can also provide insight into the existence and propagation of disbonds in SLJs. To demonstrate that ability, we embedded three butterfly MOFBG shear stress sensors in a SLJ at the specific locations where the magnitude of the peel stress is minimal (in the center and near the edges). We subjected the sample to a cyclic tensile loading test and a fatigue test wherein the response of the three sensors illustrates their (collective) ability to detect disbond initiation and propagation.

By reconstructing the response of the three sensors using 2D finite element analysis, we could derive the length of the cracks on both sides of the SLJ. Indeed, as long as the bond line remains intact, the ratios R12 and R32 (representing the response of a MOFBG shear sensor at the edge of the SLJ compared with that of a sensor in the center of the SLJ) will nearly remain constant, independently of the loading level. However, once a significant disbond starts to appear at one or both sides, these ratios will change (see Fig. 2).

Using the three butterfly MOFBG shear stress sensors, the minimum length of a detectable disbond is 100 μm, while the exact loading level does not need to be known (but should be above 17% of the failure load).

Combining Bragg gratings with specialty microstructured fibers adds new momentum to optical-fiber-based sensor applications. Considering the level of maturity that is already achieved by FBGs and MOFs as separate technologies, we are confident that their combination can rapidly gain industrial maturity and enable new structural health monitoring applications.

REFERENCES

1. P. St. J. Russell, J. Lightw. Technol., 24, 12, 4729–4749 (2006).

2. S. Pissadakis and S. Selleri, Optofluidics, Sensors and Actuators in Microstructured Optical Fibers, 1st Edition, Woodhead Publishing, An imprint of Elsevier, Amsterdam, Netherlands (2015).

3. A. Cusano et al., Fiber Bragg Grating Sensors: Recent Advancements, Industrial Applications and Market Exploitation, Bentham Science Publishers, Beijing, China (2011).

4. F. Berghmans et al., Laser Photonics Rev., 8, 1, 27–52 (2014).

5. T. Geernaert et al., J. Lightw. Technol., 28, 10, 1459–1467 (2010).

6. C. Sonnenfeld et al., Sensors, 11, 12, 2566–2579 (2011).

7. S. Sulejmani et al., IEEE Photon. Technol. Lett., 24, 6, 527–529 (2012).

8. C. Sonnenfeld et al., Smart Mater. Struct., 24, 5, 055003 (2015).

9. S. Sulejmani et al., "Fiber Bragg grating-based shear strain sensors for adhesive bond monitoring," Proc. SPIE, 9128 (2014).

Thomas Geernaert is postdoc fellow of the Research Foundation-Flanders (FWO), Francis Berghmans is full professor, and Hugo Thienpont is full professor, managing director of the Brussels Photonics Team, and vice-rector at the Vrije Universiteit Brussel, Pleinlaan 2, 1050 Brussels, Belgium; e-mail: [email protected]; www.b-phot.org.