FIBER LASERS: Move over, solid-state lasers– Femtosecond fiber lasers are here

JIAN LIU and LIHMEI YANG

In biomedical applications, achieving 100 fs pulsewidths has long been conceived as a barrier for high-power femtosecond fiber lasers to compete with solid-state lasers (such as 80 MHz, 1 W Ti:sapphire lasers), since most ultrafast laser applications like nonlinear imaging, tissue ablation, and coherent supercontinuum generation require pulsewidths down to that level. Over the past several years, high-power femtosecond fiber lasers have been intensively investigated both in industry and academia. Though average power as high as 200 W has been reported for many femtosecond fiber lasers, 100 fs pulsewidths are still a technical barrier for the ultrafast fiber laser community.

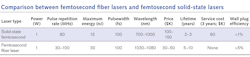

At Photonics West 2010 in San Francisco, CA, PolarOnyx broke the 100 fs bottleneck using a novel development in high-power femtosecond fiber laser technology. Using our proprietary pulse-shaping and spectral-shaping technologies, the pulsewidth of our high-power femtosecond fiber lasers was compressed to 100 fs. This significant improvement (100 fs versus 200 fs) opens a wide range of applications for femtosecond fiber lasers and will enable the aggressive replacement of solid-state lasers in addition to the already well-known fiber laser features of compactness, maintenance-free operation, and cost-effectiveness (see table). Femtosecond fiber lasers are now the enabling technology for many industrial and clinical applications.

Pulsewidth compression

The challenges to pulsewidth reduction of femtosecond fiber lasers are management of dispersion, nonlinearity, and gain narrowing. Compared to solid-state lasers, due to the relatively long length of fibers and gain medium, fiber lasers experience severe nonlinearity and gain-narrowing effects. These impact the pulse shape and spectral bandwidth and limit the compressed pulsewidth to typically 200 fs for 1 W operation. Moreover, the high-order dispersion (HOD) mismatch between fiber and grating compressor used in the femtosecond fiber laser makes this cancellation or compensation even more difficult.

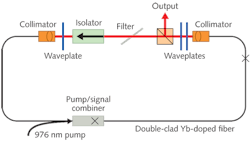

To resolve these issues, researchers at Cornell University investigated a high power modelocked fiber laser oscillator that exploits dissipative-soliton pulse shaping along with cladding pumping for high average power.1 By properly selecting the optical filter bandwidth and adjusting the polarization, stable modelocking can be achieved. The fiber laser generates 31 nJ chirped pulses at 70 MHz repetition rate, for an average power of 2.2 W. After dechirping outside the laser, 15 nJ, 80 fs pulses with 200 kW peak power are obtained (see Fig. 1).One of the key pulse-shaping techniques is to manipulate the third-order dispersion (TOD) of the fiber. Basically, the dispersion in the fiber is controlled by both material dispersion and waveguide dispersion. In the 1020–1090 nm spectral region, material dispersion shows a positive dispersion slope. With traditional fiber designs such as that for Corning's (Corning, NY) SMF-28, the TOD is always a positive number around 0.3 ps/nm2-km, which does not match the TOD of the grating compressor used. However, by manipulating the fiber waveguide structure (with a depressed cladding), waveguide dispersion can be introduced to modify the material dispersion such that the TOD and dispersion slope of the whole fiber system are matched, especially with the grating compressor.

Another key spectral shaping technique used for reducing the pulsewidth is to obtain enough pulse spectral bandwidth by taking advantage of the self-phase modulation (SPM) that may take place after the amplification stage such that the broadening spectrum will not be limited by the gain spectrum or narrowing effect of the amplifier. The fiber implemented in the amplification stage should have appropriate length in order to generate the required spectrum bandwidth. The SPM effect causes spectral broadening when the peak power of the pulse reaches a certain level. Depending on the pulse energy level and pulsewidth (that defines the peak power), the broadening factor can be optimized by selecting the right length and fiber type. Moreover, proper control of SPM can balance the TOD mismatch between the fiber stretcher and bulk-grating compressors.

These techniques resolve the tradeoff between power scaling and pulsewidth broadening, in which the amplified spectral bandwidth can support the 100 fs pulsewidth without significant residual TOD and gain-narrowing effects. Assuming transform-limited pulse quality, a 100 fs pulse is supported by a 15 nm spectral bandwidth.

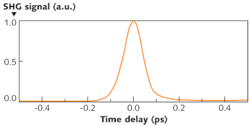

Our 1 W, 100 fs fiber laser has pulse repetition rate of 33 MHz, compressed pulse energy of 30 nJ, and average power of 1.4 W. With an operating wavelength around 1035 nm, actual measured pulsewidth is 90 fs with a Gaussian shape assumption (see Fig. 3). It has a compact compressor integrated with the fiber laser for ease of operation and reliability. For pulsewidths of 200 fs, output power levels as high as 5 W compressed have been achieved. Further optimization can be performed toward a pulsewidth of 100 fs. And by adding an optical parametric oscillator (OPO) as a supplement, the wavelength can cover from the visible to mid-infrared range, further extending the capability of femtosecond fiber lasers.Applications

Femtosecond fiber lasers provide superior advantages in terms of price, reliability, and maintenance, and are becoming a driving force for clinical applications.3

Recently, efforts to develop compact multiphoton systems for in vivo imaging and clinical applications use femtosecond pulses from ultrafast lasers coupled into double-clad photonic crystal fibers (PCFs) or hollow-core photonic bandgap fibers (PBFs). Fiber-connected miniature scanning probes have been developed to provide flexible access to tissue and to acquire multiphoton microscopy (MPM) images. While the probes are becoming smaller and smaller, the sources they use are often traditional solid-state Ti:sapphire lasers that are bulky, expensive, not portable, and require precise alignment. Finding new ultrafast laser sources that are low cost, compact, and portable is expected to enhance the impact of MPM in research and particularly in clinical studies.

Subcellular laser ablation (SLA) has emerged as a powerful tool for the measurement of mechanical properties of load-bearing cytoskeletal elements in their living, intracellular context. In SLA, high-energy laser pulses of ultrashort (100 fs) duration are focused through a high-numerical-aperture objective lens onto an intracellular target, such as an organelle or a cytoskeletal element. Using an ultrashort pulse, material at the laser focus undergoes nonlinear multiphoton absorption leading to optical breakdown and material destruction with minimal heat transfer or collateral damage to surrounding structures. Proof-of-principle studies demonstrate that these ultrafast systems are capable of destroying a single mitochondrion in a living cell without compromising the plasma membrane.4

But despite this progress, compact, fiber-delivered, user-friendly, and economical instruments are needed if femtosecond lasers are to proliferate outside of research environments and find use in multiuser biology facilities, medical clinics, manufacturing environments, and even in mobile facilities. Improved instruments will also greatly facilitate the use of femtosecond techniques in a variety of scientific research projects, particularly if the cost can be reduced. The approximately $150,000 price tag for a Ti:sapphire laser places it beyond the reach of many research groups and applications.

REFERENCES

- K. Kieu et al., Opt. Lett. 34, 5, p. 593–595 (2009).

- United States patents: 7,430,224; 7,440,173; 7,555,022; 7,477,666; 7,593,434; 7,529,278; 7,526,003; 7,430,226.

- S. Tang et al., J. Biomedical Opt. 14, 3, p. 1–3 (2009).

- N. Shen et al., Mechanics and Chemistry of Biosystems 2, p. 17–25 (2005).

Jian Liu is the founder and Lihmei Yang is director of product at PolarOnyx, 470 Lakeside Drive, Suite F, Sunnyvale, CA, 94085; e-mail: [email protected]; www.polaronyx.com.