LASER BEAM COMBINING: Coherent beam combiner yields 100 W of fiber-laser power

Over the last decade, high-power fiber lasers have gained substantial market share in industrial applications such as marking, metal cutting, and welding due to their excellent output-beam quality and high wall-plug efficiency. Sustaining this growth to become the dominant high-power source type for materials processing depends on advances in beam-combining techniques.

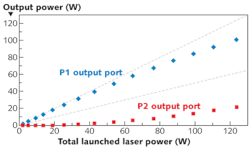

Under a Small Business Innovation Research (SBIR) project for the Air Force Research Laboratory (AFRL) Directed Energy Directorate at Kirtland Air Force Base (Albuquerque, NM), Vytran (Morganville, NJ) scientists and collaborators from AFRL and Hughes Research Laboratories (Malibu, CA) recently demonstrated all-fiber and all-passive coherent beam combining (CBC) of two, three, and four high-power fiber lasers to produce more than 100 W of single-transverse-mode output at around 1 µm. To Vytran's knowledge, this is the highest power output to date from an all-fiber, laser-based CBC without any active control.

How it was done

For laser-power upscaling, there are several technologies that can combine multiple beams. These include CBC, incoherent beam combining, and spectral beam combining. Coherent beam combining is often the preferred option, however, because it not only increases output power but also improves the brightness of the laser—a key beam characteristic.

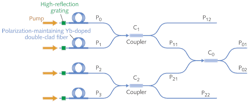

The CBC array consisted of four fiber-laser cavities with polarization-maintaining (PM) fibers and three specific couplers (see figure). Each laser cavity had a high-reflection (HR) grating, PM ytterbium (Yb)-doped double-clad fiber (DCF), and a length of PM passive fiber. The PM Yb DCF was single-mode (SM) with a numerical aperture of 0.11, normalized frequency of 2.2 at 1060 nm, 7.6 µm mode-field diameter at 1060 nm, Yb cladding absorption of 2.0 dB/m at the 975 nm wavelength, and PM beat length of 2.3 mm at 1060 nm. The HR grating had a center wavelength of 1083.0 nm with a 3 dB bandwidth of 1.2 nm and a reflectivity of greater than 99% and the length of the Yb fiber in each cavity was 10.2 m.The laser cavity was end-pumped using 975 nm multimode pump diodes from the HR end via a tapered pump combiner. Each laser output was launched into one input port of the 2 × 2 SM fiber coupler (C1 or C2) with a 50:50 coupling ratio. One output port of each coupler was flat-cleaved and the other port angle-cleaved to suppress the reflection. Two flat-cleaved ports were then spliced to two input ports of the third coupler (C0). One output of the third coupler was angle-cleaved and the other was flat-cleaved to provide a 3.4% broadband reflection.

Within this system, all lasers had the same lasing wavelength band and shared a common laser feedback. The fiber lasers reached in-phase condition spontaneously without any active control. Record power levels of over 100 W were achieved from self-organized beams in two-, three- and four-laser combinations.

Passive fiberoptic combiners

Coherent beam combining is generally realized using active phase control of each laser and is usually implemented in free space. However, since all-fiber coherent laser systems do not require active spectral stabilizers, they are preferred for reliable, compact, rugged, and efficient high-power laser systems.

The critical components for developing and demonstrating CBC are fused-fiber combiners. These combiners were developed and manufactured with the Vytran GPX-3400 glass processor—a system that produces low-loss, high-strength fused components such as pump combiners (7:1, 19:1, up to 37:1), laser combiners, tapers, large-diameter fiber splices, mode adapters, and terminating endcaps. The GPX system also performs adiabatic tapering, a process that provides lossless modal transition in the waveguide (fiber) geometry change process and also preserves the original modal quality.

"Our results not only pave the way for development of rugged, monolithic, all-fiber coherent beam-combined systems based on multiple lasers but for further scaling of laser power to the kilowatt level and beyond," said Jean-Michel Pelaprat, CEO and president of Vytran.

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.