MID-IR OPTICS: Fluoride glasses draw fiber into the mid-infrared

MOHAMMED SAAD AND JEAN-SÉBASTIEN TASSÉ

Fluoride glasses comprise a unique infrared amorphous material system that can be drawn into optical fibers and that transmits light from the ultraviolet to the mid-IR wavelengths without any absorption peak. Many properties of fluoride glass set it apart from other materials such as silica. Because silica glass becomes highly absorbing above 2 µm, fluoride glass is the material of choice for numerous mid-IR applications such as laser-beam delivery, sensing, pyrometry, and spectroscopy, in fields as diverse as medicine, defense, and astronomy. Fiber lasers with narrow emission lines in the visible and the infrared can also be made using fluoride glass because it can be doped with high concentrations of rare-earth elements.

During the 1980s and early 1990s, fluoride glasses went through extraordinary and rapid development. Most fluoride glasses offer a transmission window from 0.25 µm in the UV to 6 to 8 µm in the mid-IR, and have low theoretical losses (0.001 dB/km at 2.6 µm), making them a preferred material for ultra-low-loss optical fiber for repeaterless communication links. Even though losses close to the theoretical values have not been attained, the initial work aimed at long-haul telecom applications has made the technology mature enough to produce high-quality optical fibers suitable for short-length applications. Commercial single-mode and multimode optical fibers are now available with attenuations lower than 0.1 dB/m and proof strength greater than 100 kpsi, depending on fiber type and composition. Small bend radii of less than 0.5 cm are routinely obtained for 125 µm fibers.

Unique physical properties

The varied and numerous families of fluoride glass include fluorozirconate, fluoraluminate, fluorindate, and fluorogallate. By adjusting the composition in each family, glass properties can be tailored to meet various requirements. Stable compositions have been obtained for each family, most notably with zirconium-based compositions.

Fluoride glass has a refractive index ranging from 1.46 to 1.57, which provides low Fresnel losses of less than 4% per end face. Fluoride glass also has the very unusual property of exhibiting a negative dn/dT of around -1 × 10-5 K-1, which minimizes thermal lensing when the glass is heated.

Though fluoride glass is more sensitive to liquid water than silica glass, atmospheric moisture has very limited effect. Fluoride fibers with adequate sleeving and sheathing have been used in industrial environments for years without any degradation of their optical and mechanical properties.

Optical fibers

Unlike silica-based fibers, fluoride glass preforms cannot be prepared by modified chemical-vapor deposition (MCVD), the technique most suitable for the preparation of ultra-high-quality preforms and fibers. Fluoride glass preforms, therefore, are typically prepared by melting and casting. The resulting preforms are smaller than silica ones, but they can still be drawn into 125 µm fibers of more than 1 km in length.

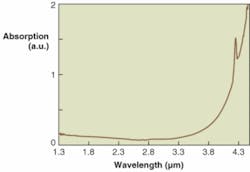

Multimode fibers with core dimension from 20 to 900 µm and absorption loss less than 0.1 dB/m can be drawn from the same preforms. Other than fiber preforms, this melting and casting technique also allows the casting of standard and unusually shaped windows and lens blanks. In a typical 200-µm-core fluorozirconate fiber, the transmission is quite flat in the infrared region, which is an attractive property for spectroscopy and pyrometry applications (see Fig. 1).

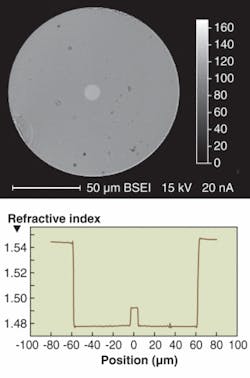

Geometric parameters such as concentricity and core diameter are more critical for single-mode than multimode fiber. This makes infrared single-mode fiber preparation, in general, a big challenge. The core has to be well centered in the cladding, and the core diameter has to be very constant along the fiber.

Different approaches have been successfully used to produce single-mode fibers. Almost all are similar to methods used for silica-based fibers but adapted to infrared glasses. IRphotonics has developed a unique method to obtain a well-centered core and stable diameter along the fiber that varies less than 1 µm over hundreds of meters.

Doped and undoped single-mode fibers have been successfully manufactured featuring core diameters from 4 to 20 µm. Rare-earth concentrations can be as high as 50,000 parts per million, significantly higher than silica fibers (see Fig. 2).

Passive applications

Lasers of different wavelengths (Nd:YAG, Ho:YAG, Er:YAG, and CO2) are increasingly used in medical applications as a more efficient and precise alternative to the surgeon’s scalpel and the dentist’s drill. Compared to an articulated arm, fibers offer a potentially more-flexible and cost-effective solution. The use of fibers for transmitting light above 2 µm, however, has been limited by the high absorption of silica-based fibers over this wavelength.

Erbium-doped YAG lasers are becoming increasingly popular in medical applications, especially in dentistry, skin resurfacing, and urology, because they transmit at a wavelength of 2.9 µm, which corresponds exactly to the absorption peak of water. Fluoride-glass fibers are the fiber of choice for such applications, because they are flexible and show the lowest attenuation at 2.9 µm. In addition, low Fresnel losses of less than 4% per face allow an overall transmission greater than 85% for a typical 2 m fiber-delivered medical system. The small bend radius of 4 cm for a 450-µm-core fiber gives the fiber a great flexibility. Furthermore, the same fiber can transmit a visible pointing beam.

Most organic molecules and some gases have fundamental absorption peaks in the 2-to-5 µm spectrum. An infrared optical fiber connected to a Fourier-transform IR spectrometer is able to measure very low concentrations of these substances. Optical fibers are very useful for remote spectroscopy because they are easily implemented in a production line. They can also facilitate quality control and multiple-point control.

Institut National d’Optique (INO; Quebec City, Quebec, Canada) has developed a system to monitor hydrogen fluoride gas concentration in a chimney of an aluminum factory. A fluoride glass fiber carries the IR signal from the chimney to a spectrometer located more than 50 m away. A fluoride glass fiber can be used as well between the light source and the sample. The same technique can be adapted to analyze other molecules.

Pyrometry, the science of temperature measurement, can take advantage of the wide transmission spectrum of fluoride fibers. Indeed, according to the blackbody emission theory, the peak wavelength emission of a body changes with temperature. The low attenuation and flat transmission spectrum of fluoride fibers therefore allow precise determination of much lower temperatures than silica fibers in shock physics experiments in which targets are subject to extreme temperature and pressure conditions.

Fluoride fibers have also proven useful in shortwave IR (SWIR; 0.7-2.5 µm) and midwave IR (MWIR; 3-5 µm) homeland-security applications because they permit remote identification of chemical threats. Signals from hot objects like plane engines, or IR countermeasures for fooling heat-seeking missiles can also be transmitted by fluoride glass fibers.

Sensing and astronomical interferometry are additional passive applications that can take advantage of fluoride fibers’ low loss and wide transmission window.

Active applications

Fiber lasers offer many advantages over solid-state lasers including high wall-plug efficiency, excellent beam quality, and compactness. And fluoride glass fiber can contain rare-earth-element concentrations higher than those obtained with silica and chalcogenide glass fibers, which translates into a greater lasing efficiency and therefore shorter fibers. Doped fluoride glass fibers, likewise, show more active laser lines in the visible, near-IR, and mid-IR than conventional and nonconventional glass fibers.

Doped and codoped fluoride glass fibers can be drawn into exotic geometries such as D-shapes and rectangular double-clad forms to suit different fiber-laser requirements (such as pumping configuration and lasing efficiency). Fiber lasers have been made from fluoride glass fiber using different rare-earth elements such as erbium, holmium, thulium, neodymium, and praseodymium. And fiber lasers with high power levels have been demonstrated, such as 10 W at 2.74 µm, which was achieved using a 4-m-long erbium-doped ZBLAN fiber.

MOHAMMED SAAD is the CTO and founder, and JEAN-SÉBASTIEN TASSÉ is the sales manager at IRphotonics, 627 McCaffrey, Montréal (Québec), Canada H4T 1N3; e-mail: [email protected]; www.irphotonics.com.