After years of development, fiberoptic networks are finally starting to appear in luxury automobiles. The first applications are in high-end broadband entertainment and information systems, linking compact-disc (CD) changers, audio systems, and speakers throughout the car, delivering navigation information to the driver, and providing video entertainment to passengers. Also in development are fiber systems that transmit safety-critical control and sensor information throughout the car. The initial versions of both types are based on polymethyl methacrylate (PMMA) step-index fiber, but developers are looking at hard-clad silica fiber for future generations.

The evolving automobile

Automotive engineers began thinking seriously about fiberoptics more than two decades ago. Their original goal was to prevent electromagnetic interference from impairing the operation of early electronic systems such as antilock brakes. However, it proved more cost-effective to make the electronic systems less sensitive, so fiberoptics remained on the shelf until a new generation of automotive electronics began challenging the capabilities of copper.

In the late 1990s, the automotive industry grew enthusiastic about the prospects for "telematics," an often-vague vision of equipping cars with a host of new information and entertainment systems. The tremendous inertia of the auto industry damped the wave of enthusiasm, avoiding the excesses of the Internet bubble, and telematics has never taken off.

Nonetheless, new electronic systems are finding their way into luxury cars, including navigation systems, elaborate stereos with multiple speakers, and video systems with back-seat screens to entertain passengers. Electronic control and sensing systems are growing in sophistication. These new technologies are pushing the limits of the traditional automotive wiring harness, which carries both electrical power and control signals.

To get around these limitations, cost-conscious automotive engineers are finally turning to optical fiber—step-index multimode plastic fiber with a 1000-µm core made from PMMA. Its attenuation is too high for most other applications and its bandwidth is low, but plastic fiber is adequate to cable even the most gigantic sport-utility vehicle. This has helped reduce costs to the point at which fibers are going into optional systems on luxury cars, the traditional starting place for new automotive technology.

New standards are required for automotive use of plastic fibers. Cars present a much tougher environment than home electronics. They can be left outside in conditions ranging from a steamy Miami summer with the sun dead overhead, to a frozen Manitoba winter where the sun rises 15° above the horizon and the temperatures hit -40°C. The automotive industry wants fibers able to withstand temperatures to 85°C, well above the 65°C standard for indoor consumer electronics. Connectors must be both cheap and durable. "Temperature and vibration are huge issues, so a lot more robust design is required," says Pom Malhotra, program manager at the Automotive Multimedia Interface Collaboration (Bloomfield Hills, MI).

Two distinct types of fiber systems have been developed. One type is optimized for multimedia interfaces carrying audio, video, and digital data, from digital versatile disc (DVD) players to navigation systems, which provide amenities that are not vital for safe operation of the car. The other type carries safety-critical signals, such as those controlling turn signals, windshield wipers, and brakes.

Media-oriented systems transport

MOST Cooperation (Karlsruhe, Germany) was founded in 1998 to develop a multimedia network called media-oriented systems transport (MOST). The goal is to transmit signals at rates from a few kilobits per second to 25 Mbit/s with a "plug and play" user interface. The standard includes a stack of seven layers from application to physical layer—such as in the global telecommunication network—that are hidden from users. Devices meeting the open standard can be used in any car that complies with it.

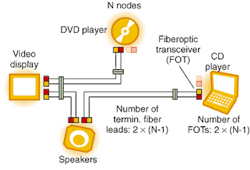

FIGURE 1. In a MOST network, fiber links form a ring connecting components such as mobile phone receivers, radios, speakers, DVD and CD players, computers, and speakers.

null

Fibers in a MOST network run from point to point between devices, which have a pair of ports and are assembled in a ring (see Fig. 1). The transmitters are 650-nm red light-emitting diodes (LEDs), which emit 0.1 to 0.75 mW and are directly modulated with an extinction ratio of at least 10 dB. The receivers are based on PIN photodiodes. The signals are converted to electronic form at each device, then retransmitted around the ring, which is able to support up to 64 devices, including mobile-phone receivers, stereos, computers, DVD players, video displays, and speakers, which automatically initialize when plugged into the network.

Signal transmission for all devices is synchronized to a master clock that controls the network, allowing the use of simple transmitters and receivers and avoiding the need for buffering. The network can carry synchronous data streams to 25 Mbit/s for applications such as video, and handle asynchronous data at total rates to 14.4 Mbit/s. A dedicated control channel carries 700 kbit/s. All analog signals are converted to digital before transmission. The structure allows single- or bidirectional transmission, depending on device requirements.

Car makers are already producing high-end models equipped with MOST hardware. Already in production are the Audi A-8, the BMW 7 Series, the Mercedes E class, the Porsche Cayenne, the Saab 9-3, and the Volvo XC-90. Jaguar, Land Rover, Fiat, Peugeot, and Citroen also are producing MOST cars. Both BMW and Mercedes have announced plans to equip all their lines of cars with MOST networks, and other manufacturers also plan to introduce MOST-equipped cars. The same technology can be used in home electronics networks.

Developers plan to enhance MOST transmission rates to 50 and 150 Mbit/s, and possibly even to 1 Gbit/s. Above 100 Mbit/s, hard-clad silica fibers and vertical-cavity surface-emitting laser transmitters will replace plastic fibers and red LEDs. Both DaimlerChrysler and Yazaki North America (Canton, MI) showed high-speed prototypes at last year's Convergence show in Detroit.

1394 networks

The 1394 Trade Association, best known for its FireWire standard for video and computer data transfer, has an Automotive Working Group developing a version of the standard for car use. Like MOST, the 1394 standard has seven layers, with point-to-point links running between plug-and-play devices. However, the topology is a tree or star, with devices branching out from each other rather than arranged in a ring like MOST (see Fig. 2). The point-to-point links between devices contain two fibers, one for sending data, the other for receiving it. The 1394 standard does not specify wavelength, but typically 650-nm LEDs are used with plastic fibers.

FIGURE 2. In the tree geometry of the 1394 network, point-to-point links branch off other devices. Typically two fibers run between devices, one for sending and one for receiving.

null

Unlike MOST, the 1394 standard accommodates several types of cable: 1000-µm plastic fiber, hard-clad glass fibers, shielded twisted-pair copper cable, and category 5 copper cable. Each link can run up to 100 m between devices, and the network can contain a total of 63 devices. The design can handle both streaming video signals and asynchronous signals such as computer data.

The original copper-cable version of the 1394 standard operated at up to 400 Mbit/s, but was limited to runs of 4.5 m by the use of copper cable. The enhanced 1394b version can carry data rates to 800 Mbit/s over distances to 100 m over plastic fiber or category-5 cable. Future plans call for increasing data rates to 3.2 Gbit/s. The final standards are in the approval process.

Byteflight

The Byteflight protocol, developed by BMW in conjunction with several electronics firms, is intended for safety-critical applications. It transmits at 10 Mbit/s using a flexible time-division multiple-access protocol, an architecture that guarantees a fixed latency time for high-priority messages from critical components, while allowing lower-priority messages to use the remaining bandwidth. This deterministic behavior is vital for safety. Developers picked optical fiber because of its immunity to electromagnetic interference.

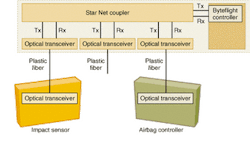

The network is an active star system, with plastic fibers running between individual devices and a central active coupler, which is a dedicated integrated electronic circuit. Optical transceivers at the device and coupler ends convert the optical signals to electronic form (see Fig. 3). Each transceiver consists of a red LED mounted on top of a photodiode receiver, so both are coupled effectively to the same plastic fiber. The active star coupler receives the electronic signals and distributes them back to all working nodes. It generates clock and control signals, and can both regenerate input signals and switch off nodes that generate garbage signals. Devices can be connected to two active stars for redundancy.

FIGURE 3. In a Byteflight network, all signals go through an active coupler, which processes them in electronic form, then redistributes them to other devices.

null

BMW began using Byteflight in its 7 Series cars in 2001, in which 13 electronic control units are connected, including accelerometers and pressure sensors to detect when seats are occupied. Transmission shifting is also done through the fiber network. Last year, BMW added Byteflight to control the airbag system on its new Z4 roadster, and this year will extend fiberoptic airbag control to its new 5 Series cars.

A slow spread likely

It may take time for fiber to spread beyond high-end luxury cars, says Paul Hansen, editor of the Hansen Report, an auto-electronics newsletter in Portsmouth, NH. Fiber costs remain higher than those for copper cable, but fiber costs will come down as production increases. Auto-industry manufacturing engineers can be relied on to squeeze every penny they can out of the production process, while quality-control engineers will monitor how well fiber performs. But there's a steep price differential between economy cars and the luxury models that now come with fiber options.

Mass production of plastic fibers could help the technology spread to home electronics and office networks. The 1394 standard is already used in many video links and computers. MOST is looking at similar applications. As prices drop and performance improves, low-cost fiber links could find many more uses.

ACKNOWLEDGMENTS

Thanks to Josef Berwanger, BMW; Paul Hansen, the Hansen Report; Pom Malhotra, Automotive Multimedia Interface Collaboration; Larry Matola, Delphi; and Jim Minewiser, MOST.

Resources

1394 Trade Association: http://www.1394ta.com

Automotive Multimedia Interface Collaboration: http://www.ami-c.org

Byteflight http://www.byteflight.com

Hansen Report on Automotive Electronics: http://www.hansenreport.com

MOST Cooperation: http://www.mostcooperation.com