Fiber lasers achieve world-record powers

Record-breaking output power in certain types of fiber lasers has been claimed by researchers from Southampton Photonics (SPI; Southampton, England) and the Optoelectronics Research Center (ORC; University of Southampton, England). At the Photonics West Conference (Jan. 25–23; San Jose, CA) cladding-pumped fiber lasers emitting at 1080 and 1565 nm were reported with output powers of 272 and 103 W, respectively.1 A 977-nm-emitting laser with near-diffraction-limited quality and an output power of 3.5 W was announced at the Advanced Solid State Photonics conference (Feb. 2–5; San Antonio, TX; see figure).2

In laboratory experiments, laser scientist Johan Nilsson and Southampton colleagues achieved more than 270 W of single-mode output power at 1080 nm from an ytterbium-doped fiber laser and more than 100 W of single-mode output power at 1565 nm from an erbium-ytterbium-doped fiber laser. The SPI researchers believe these are the highest powers ever produced using ytterbium and erbium-ytterbium single-mode fiber lasers. Ytterbium-doped fiber lasers are among the most efficient of all rare-earth-doped fiber lasers, and erbium-ytterbium co-doped fiber lasers are the most efficient type of high-power laser in the eye-safe wavelength region near 1550 nm.

Fiber lasers are smaller and need less alignment than conventional lasers. However, high power approaching 1 kW in cladding-pumped fiber lasers is necessary to replace traditional lasers for high-power applications. The most promising uses of fiber lasers with high power are in broadband erbium-doped fiber amplifiers (EDFAs), tunable fiber lasers with broad wavelength emission in glass hosts, and pulsed sources.

With the appropriate fiber designs, SPI expects single-mode fiber lasers with 1 kW of output power to be achieved in the near future. The limitation to overcome, say Nilsson and colleagues, is the available power in existing pump sources. Recent rapid improvements in available power are expected to continue and spread to more-refined fiber lasers with single polarization, narrow linewidths, and pulsed sources. "Fiber lasers are leading candidates for various high-power applications, and will be chosen over bulk lasers, not least when the broad linewidths of glass hosts are advantageous," says Nilsson.

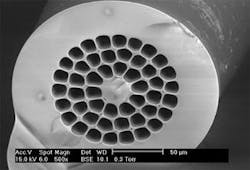

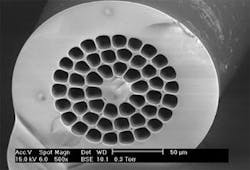

A further world-record power of 3.5 W was obtained from a 980-nm laser using ytterbium ring-doped-cladding pump technology. In this experiment, a high-brightness pump module was used to deliver 5 W of multimode power in a 35-µm beam. A holey fiber, called a jacketed air-clad fiber, was then fabricated with a 35-µm-thick cladding suspended in air. The ring-doping technology incorporates the ytterbium ions in a ring around a single-mode core of the fiber, which reduces 980-nm absorption and gain from the undesirable 1040-nm radiation.

The result is a single-mode 980-nm fiber laser with a threshold of 400 mW and 42% slope efficiency, an attractive source for high-power pumping of erbium-doped fibers and in pump-sharing schemes. Frequency doubling of 980-nm fiber lasers to 490 or 488 nm could enable them to replace argon-ion lasers in biomedical and analytical instrumentation, says Nilsson.

REFERENCES

- J. Nilsson et al., SPIE Proc., Photonics West, San Jose, CA, 2003.

- K. H. Ylä-Jarkko et al., Proc. Adv. Solid State Photonics, San Antonio, TX, 2003.