High-power Fiber Lasers: Ultrafast fiber laser reaches gigawatt peak powers

Fiber-based laser systems are well known for laser architectures that offer scalable average power. Because of their outstanding efficiency, excellent light confinement in the waveguide structures, and rapid heat dissipation, several kilowatts of continuous-wave power have been demonstrated in a diffraction-limited beam.

In contrast, ultrafast fiber lasers lag behind their bulky solid-state counterparts in terms of performance and have not been considered the optimal choice for a high-peak-power laser source. Fiber-based generation of high-energy femtosecond pulses is thus the ultimate challenge; if successful, the combination of high energy and high average power would enable paramount performance.

Increasing peak power

Fiber lasers have peak-power limitations because of tight confinement of the radiation over the entire fiber length, which causes nonlinear pulse distortions through self-phase modulation (SPM). The most intuitive and common way to suppress these effects is to reduce the pulse intensity by stretching the pulse in time using the well-known chirped-pulse amplification (CPA) technique. Over the years, our group at Friedrich Schiller University has demonstrated average-power capabilities of femtosecond ytterbium-doped fiber CPA systems by achieving 131 W of average power in 220 fs pulses.1 Despite the temporal stretching, which becomes increasingly impractical with increasing stretched-pulse duration, the impact of SPM cannot be avoided when pushing the system to higher output energies.

A quantity that describes the amount of accumulated nonlinear phase by SPM is the so-called B-integral. Above a B-integral of π the regime of nonlinear pulse amplification is entered and in general, a degradation of pulse quality is observed; that is, pulse broadening and evolution of pre- and post-pulses effectively reduces the peak power.

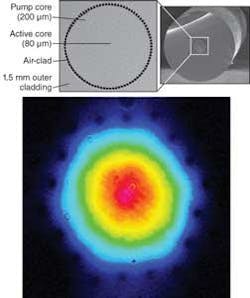

In addition to temporal stretching, mode-area scaling in the amplifier fibers is required to reduce the pulse peak intensity during amplification, and therefore, keep the B-integral as low as possible. To do this, a significant enhancement of single-mode core size has been demonstrated by certain photonic-crystal fiber designs, such as state-of-the-art rod-type photonic-crystal fiber.2 This fiber design is characterized by a very large mode area together with a very short absorption length (less than 1 m), creating ultralow nonlinearity. The waveguide structures for signal and pump radiation are surrounded by a very large fused-silica outer cladding making the fiber stiff and self-supporting without the need for a protective polymer coating. The large fundamental core mode is thereby protected from any bending-induced distortion and mode-area reduction, which is typically observed when large-mode-area fibers are coiled. This rod-type fiber concept enables the large mode size to be maintained over the entire fiber length, leading to the most effective exploitation of its low nonlinearity. In addition, lack of a polymer coating makes high-average-power extraction possible without thermal issues.

Experimental setup

Recently, our group implemented a high-average-power millijoule-pulse-energy femtosecond fiber CPA system based on an 80 µm ytterbium-doped-core photonic-crystal fiber as the main amplifier (see Fig. 1). The setup consists of a passively modelocked ytterbium-doped potassium gadolinium tungstate (Yb:KGW) oscillator, a dielectric grating stretcher-compressor unit, an acousto-optical modulator as pulse selector, and two Yb-doped photonic-crystal fibers used in single-pass configuration as amplification stages, providing an overall gain factor of approximately 25000.

The long-cavity Yb:KGW oscillator delivers transform-limited 400 fs pulses at a repetition rate of 9.7 MHz and an average power of 1.6 W at 1030 nm center wavelength. The stretcher-compressor-unit uses two 1740 lines/mm dielectric diffraction gratings on a 1.5 × 0.5 m footprint, and stretches the 3.3 nm bandwidth pulses to 2 ns. The throughput efficiency of the stretcher is 60%. Pulse repetition rate is reduced by a quartz-based acousto-optical modulator with diffraction efficiency as high as 75%.

The preamplifier comprises a 1.2-m-long 40-µm-core single-polarization air-clad photonic-crystal fiber having an inner cladding diameter of 170 µm that is pumped by a fiber-coupled diode laser emitting at 976 nm. This configuration is capable of delivering a single-pass gain as high as 35 dB and average powers up to 6 W. However, we have operated the preamplifier just up to a few microjoules of pulse energy to avoid excessive accumulation of nonlinear phase in this stage.

Finally, the main amplifier is constructed using the previously described low-nonlinearity air-cladding photonic-crystal rod-type fiber (see Fig. 2). Its inner cladding has a diameter of 200 µm (numerical aperture of 0.58), and the active core is as large as 80 µm. This structure possesses a small signal pump-light absorption of 30 dB/m at 976 nm. The uncoated fiber is embedded in a water-cooled aluminum body. Although the core supports very few transverse modes, stable excitation of the fundamental mode only is achieved by seed-mode matching. This 1.2-m-long rod-type fiber has a mode-field diameter as large as 71 µm, corresponding to an effective mode-field area of 4000 µm2. Output beam quality, characterized by an M2 value of less than 1.2, is power independent.The output spectrum of this high-performance fiber CPA system at the highest extracted pulse energy is characterized by a 2.9 nm width (full width half maximum) and a 7.5 nm bandwidth defined by the stretcher-compressor unit. Only minor gain narrowing is observed for the power levels reported. Amplified spontaneous emission and intermediated (nonselected) pulses are suppressed to better than 35 dB. A larger wavelength scan of the spectrum excludes the onset of stimulated Raman scattering.

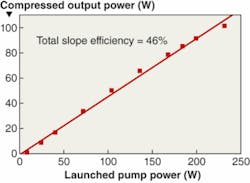

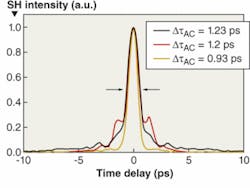

The grating distance in the compressor is continuously adjusted for minimal autocorrelation width. At 500 µJ the width is measured to be 1.2 ps, corresponding to a pulse duration of 780 fs assuming a sech2 pulse shape (see Fig. 4). For comparison, the autocorrelation trace at very low pulse energy reveals a wing structure that grows with pulse energy, which can be attributed to the imposed nonlinear phase (SPM). The total B-integral in this case is calculated to be 4.7. Further increase of pulse energy without further degradation of pulse quality is possible by decreasing the seed power launched into the main amplifier. This reduces the B-integral of the preamplifier and the effective fiber length of the main amplifier and hence the accumulated nonlinearity. However, the extraction efficiency is reduced due to increased pump-light absorption saturation.At 100 kHz repetition rate, a launched pump power of 220 W and a seed average power of 100 mW were necessary to extract 100 W of average power corresponding to 1 mJ of pulse energy, leading to 700 µJ compressed pulse energy. At 50 kHz repetition rate and 70 mW seed power we achieved 71 W of average power with a pump power of 180 W, corresponding to 1.45 mJ energy. In this case the B-integral is as low as 7. The compressed pulses exhibit an autocorrelation width of 1.23 ps (equivalent to 800 fs pulse duration) and a pulse energy as high as 1 mJ. The corresponding pulse peak power reaches approximately 1 GW. To our knowledge, these are the highest pulse energies and peak powers ever reported for fiber-based ultrafast-laser systems.

Power scaling

To investigate the average-power scaling potential of the rod-type photonic-crystal fiber amplifier beyond the demonstrated performance, we built a simple continuous-wave laser cavity. Pumping this fiber from both ends with 976 nm fiber-coupled diode lasers produced a maximum output power of more than 700 W. The output increased linearly with a slope efficiency of 66 % and was only pump-power limited; no rollover was observable.

This 700 W value corresponds to an extracted power per unit length of 570 W/m. Even at this high extracted power level, laser operation was stable and no thermal degradation occurred. As a result, we are confident of its potential for millijoule pulse energies at megahertz repetition rates corresponding to kilowatt output power levels, opening up new possibilities in numerous scientific and real-world applications, such as high-speed, high-precision micromachining, and driving high-field physics experiments at previously unimagined high repetition rates.

REFERENCES

1. F. Röser et al., Optics Lett. 30(20) 2754 (2005).

2. J. Limpert et al., Optics Exp. 14(7) 2715 (2006).

About the Author

Jens Limpert

Professor for Physics, Department of Fiber & Waveguide Lasers at Friedrich Schiller University

Jens Limpert is Professor for Physics and leads the department of Fiber & Waveguide Lasers at Friedrich Schiller University (Jena, Germany).

Andreas Tünnermann

Andreas Tünnermann is director of the Fraunhofer Institute for Applied Optics and Precision Engineering (Fraunhofer IOF), as well as a professor in physics and director of the Institute of Applied Physics at Friedrich Schiller University (both in Jena, Germany).

Fabian Röser

Ph.D. Student, Friedrich-Schiller-Universität Jena

Fabian Röser is a Ph.D. student at the Institute of Applied Physics and the Fraunhofer Institute of Applied Optics and Precision Engineering at Friedrich-Schiller-Universität Jena (Jena, Germany).