Fiber-optic Sensing: Pressure-sensing, embedded-core capillary fibers improve on complex microstructured optical fiber designs

Numerous designs exist for microstructured and/or photonic-crystal optical fibers used as pressure sensors for medical and industrial applications such as downhole oil exploration and recovery. The fibers are designed such that an external load triggers asymmetric stresses within the fiber that cause refractive-index variations that can be measured and translated into induced pressure values. Unfortunately, the microstructured designs for these fibers are quite complex and result in fragile, delicate sensors from fibers that are difficult to fabricate and do not lend themselves to standard optical-fiber drawing processes.

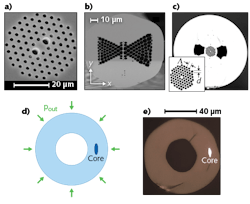

Understanding that an asymmetric form within an optical fiber is necessary to alter refractive index under stress, researchers at the Universidade Estadual de Campinas (Unicamp) and at the Instituto de Estudos Avançados (IEAv), both in São Paulo, Brazil, have improved on traditional microstructured designs by developing a much-less-complex embedded-core capillary fiber that can be drawn using traditional methods and optimized through software to perform with comparable sensitivity to more-expensive, complex microstructured optical fibers (see figure).1

Embedding cores and COMSOL optimization

To create asymmetry with applied pressure, a silica capillary tube with 80 and 40 µm outer and inner diameter, respectively, is fabricated with a germanium (Ge)-doped oval-shaped region within the wall of the capillary tube. But before the position and size of this region could be optimized, the researchers first used an analytical model to explore how applied pressure affected birefringence of a capillary tube without the Ge region.

The analytical model revealed that applied pressure (50 bar outside, 1 bar inside) generates an asymmetrical stress distribution inside the capillary tube through the photoelastic effect, with stresses causing variation in the material refractive index that differ in horizontal and vertical directions to create birefringence.

Using COMSOL (Burlington, MA) Multiphysics software, the Ge-doped elliptical region was then added to the mathematical model and modal birefringence was analyzed as a function of position of the elliptical region within the capillary wall. The resulting finite-element-based model showed that birefringence is maximized when the elliptical region is very close to the innermost wall of the capillary tube, roughly 2 µm into the wall for this particular capillary tube.

To test performance of the embedded-core capillary fiber as a pressure sensor, a capillary tube with 40 µm inner diameter and 100 µm outer diameter with an embedded core (with elliptical axes lengths of 11 and 3.5 µm) positioned 35 µm from the center of the capillary tube was analyzed under pressure using polarimetric wavelength scanning. That is, a supercontinuum source injected light into the fiber under various pressure values and polarizing filters separated the orthogonal modes of the transmission and compared the results via an optical spectrum analyzer.

Sensitivity values of around 1 nm/bar for the embedded-core capillary fibers were better than microstructured fibers that have sensitivity values of around 0.3 nm/bar, while birefringence derivative values were comparable to microstructured designs.

“Though many complex fiber-optic pressure sensor designs have been demonstrated in the literature, we have reached a very simple design that combines microstructured fiber and the basic concepts of the elasto-optic effect,” says IEAv professor Marcos A. R. Franco. “The proposed design can be adapted to work in different ranges of pressure and perform punctual or distributed measurements by optical backscatter reflectometry.”

“This work presents a new route to produce ultrasensitive hydrostatic pressure sensors with room for optimization by fine geometrical adjustments on the fiber parameters,” says Cristiano Cordeiro, Unicamp professor. “Undersea long-distance pressure monitoring is a likely target application. Our research groups are now exploring and modeling new fiber designs and fabrication procedures based on additive manufacturing,” he adds.

REFERENCE

1. See https://goo.gl/s9Xj1n.

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.